Screw for Router Communicationc Equipment Okorder.com

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 10000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1, Screw for Router Communicationc Equipment

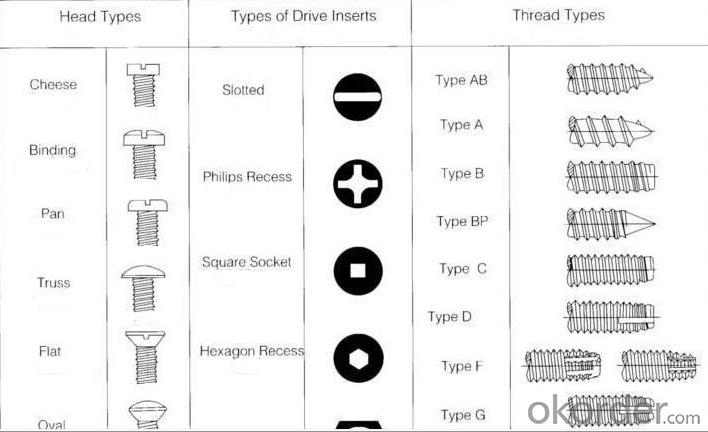

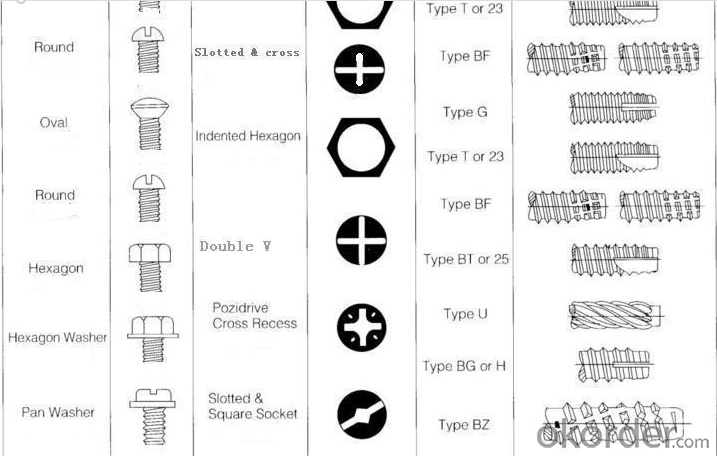

| Phillips Button Head Screw For Communications Equipment | |

| Material | SS304 |

| Dimension | As customer's request |

| Head shapes | Button head |

| Driver types | Phillips |

| Screw thread | Coarse thread |

| Screw tip | Flat point |

| Finish | Plain |

| Features | Good anti-corrosion ability |

| Grade | A2 |

| Certification | ISO9001, ROHS, SGS, CTI |

After-sale service | If there are any quality problems, please contact with us at once |

3,products show and packing details

Term | USD/1000 pcs FOB shanghai |

Payment | T/T |

Packing | Bulk in master carton or small box packing |

Delivery Time | 30 Days after order confirm |

Place of Origin | China |

4,FAQ

Q: WHAT ARE YOUR ADVANTAGES?

A: 1. We have a specialized team in dealing with all the documents required by customers. We aim to zero error to save money and time for client. 2. We have a strict quality control from production to delivery. 3. We take use of advanced system and tool to improve working efficiency and control every step. 4. Professional sales team to serve customers. 5. Samples can be provided as your requirements. 6. Professional packing team which keep every packing safely.

Q: WHAT ARE YOUR MAIN PRODUCT?

A: We are specializing in providing cold rolled 201/410/430 Stainless Steel Coil / Stainless Steel Strip / Stainless Steel Sheet / Stainless Steel Plate, Stainless Steel Circle, Stainless Steel tube / Stainless Steel Pipe Sheets.

Q: CAN I GET FREE SAMPLE?

A: YES. We can provide free sample. However, you should be responsible for the transportation freight. Please tell us your express account or please send us the transportation freight of samples firstly, then we can arrange sample delivery.

Q: HOW MUCH THE TRANSPORTATION FREIGHT WILL BE FOR THE SAMPLES?

A: The freight depends on the weight and packing size and your area.

- Q: The Symbolic Meaning of Screw

- The "crazy screw" is in the life and employment under the dual pressure, long-term super-strength, over time limit of labor, the spirit of life, , Constantly challenge the physical and psychological limits of a group of people, they bear the hard work day and night, physically and mentally tired tired, gather more away from the family, is the new era of labor and employment environment of a deformed landscape.

- Q: What is the meaning of the 8.8 on the screw

- 8.8 is a high-strength screw! 6.8 is the strength of 4.8 is the national standard screws the highest high-strength screws is 12.9 I have seen the best and most exquisite

- Q: Screws are not slopes.

- Yes, the inclination of the object can be seen as a slope This can be seen as a slide, the slide is a slope. The slope is a simple machine. The screw is screwed into a cylindrical slope, the thread on the screw is like the pattern formed in Figure (A), the length of a circle of threads is equivalent to the length of the slope.

- Q: I'm talking about another thing

- crews for the daily life of indispensable industrial necessities: such as cameras, glasses, watches, electronics and other small screws used; television, electrical products, musical instruments, furniture and other general screws; as works, construction, bridges are large Screws, nuts; transport equipment, aircraft, trams, cars, etc. are the size of the screw and use. Screws have an important task in industry, and as long as there is industry on earth, the function of screws is always important. Screw is thousands of years of people in the production of common inventions, according to the application field, it is the first major inventions of mankind.

- Q: I would like to know the specifications of the two types of screws models, including length, diameter, diameter and pitch, etc.

- The specific need to check their own standard parts manual to judge

- Q: M4.8 * 25 What does it mean in screw size?

- M4.8 is the screw size 25 is the length of the screw

- Q: Was rusty rust, the screwdriver are turning how to do, is a very important thing

- Drop a few drops of oil or gently knock around a few times, to the rusty screw drops (to bubble better) gasoline or kerosene, washing the use of oxalic acid also

- Q: Why should the screw twist clockwise?

- Clockwise tightening of the screw is called orthodontic screw, counterclockwise tightening of the screw called anti-screw or left teeth screws, the general international are clockwise orthodontic screws, in a particular case will use the left teeth Screws, such as the need to fix the fan impeller, are left teeth

- Q: Who knows who invented the screw?

- The spirits were invented more than 2,000 years ago, but less than 500 years for fixing things. The first person who describes the spiral is the Greek scientist Archimedes (about 287 BC - 212 BC) The Archimedes spiral is a huge spiral in a wooden cylinder used to The water is raised from one level to another, and the fields are irrigated. Its true inventor may not be Archimedes himself. Maybe he just described something that already existed. Perhaps it was the ancient Egyptian craftsmen who had designed it to use the irrigation on both sides of the river. Archimedes spiral in the ancient society are used to raise water, no one considered to change it into a fixed piece. Archimedes spirals are widely used for water lifting. For example, the Romans used it to drain the mine. In the Middle Ages, carpenters used wooden nails or metal nails to connect furniture and wooden structures. In the 16th century, nail workers began to produce spiral nails, these nails can be more firmly connected things. It was a small step from this nail to the screw. At the end of the eighteenth century, screws were quite popular as fixed parts, because at that time a cheap production method had been found. Screwdriver (chisel) appeared in London around 1780 years. The carpenter found that screwing the screw with a screwdriver was better than a hammer and could fix something better, especially when a fine screw was encountered.

- Q: How did the screw twist?

- after the drill with the drill cap will be destroyed. The use of the principle of anti-silk will be the remaining screw drilled (you can use a broken screw-specific drill bit - broken screw out of the device)

Send your message to us

Screw for Router Communicationc Equipment Okorder.com

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 10000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords