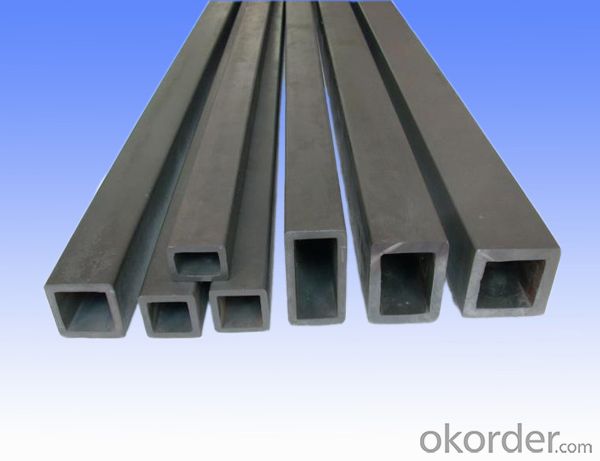

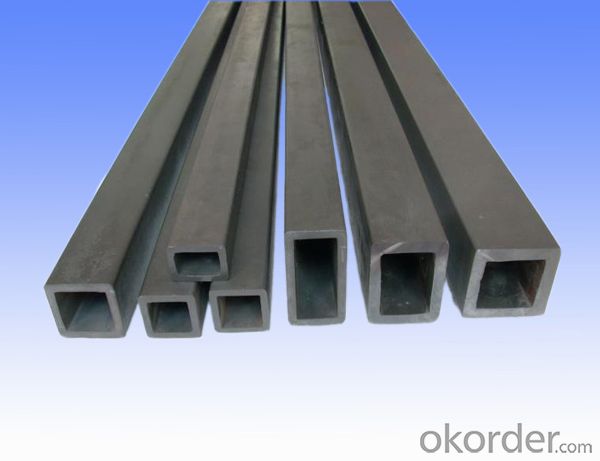

SSIC Silicon carbide tube

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 pc

- Supply Capability:

- 500 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Tailor-made for customers all kinds of pumps with my company, kettle, bearing no pressure sintering silicon carbide mechanical seal, and all kinds of resistance corrosion pump parts and the accessories. Our company pressureless sintered silicon carbide products a reaction bonded silicon carbide products, can easily adapt to the harsh working conditions, in strong corrosive, strong wear, high temperature, high pressure, high strength harsh harsh under complex conditions is more outstanding. At the same time, our company to provide customers with nozzles, armored body armor plate and other special-shaped pieces of custom-made service.

Compared with the reaction sintered silicon carbide product (SSIC), the production process of the sintered silicon carbide product (RBSIC) is complex and the production investment is high. In addition, whether it is in the resistance to corrosion and abrasion, compressive and flexural fracture resistance of or high pressure, high temperature and other properties are more excellent, this is pressureless sintering silicon carbide products will in the near future completely replace reaction bonded silicon carbide products is one of the important reasons. The main varieties of the pressureless sintering silicon carbide products with all kinds of mechanical seal with sealing ring and moving ring and static ring, corrosion resistant pump, magnetic pump, shield pump components. At the same time, the production special-shaped pieces of nozzle, wire drawing die, armor plate. According to the drawings, we will provide customers with satisfactory products and customer satisfaction. Let customer satisfaction is one of the purposes of our company has been pursued, but also one of the objectives pursued by all the staff of our company.

Features: high temperature resistance, wear resistance, corrosion resistance, oxidation resistance, hardness, heat conduction

Main products: mechanical seals, pump parts, nozzles, bullet proof plate

Mechanical seals: high hardness, high wear resistance, good self - Lubrication and high heat conductivity, so the service life of mechanical seal is greatly improved.

Pump: resistance to corrosion and wear characteristic of the pressureless sintering silicon carbide become magnetic pump sliding bearing, resistant corrosion pump sleeve, shielding pump assembly, etc. various kinds of pump of choice

Nozzle: wear resistant, high temperature resistance, high hardness characteristics of the normal pressure sintering silicon carbide nozzle to become a perfect alternative to carbide nozzle

Armor: light weight, high hardness, good ballistic performance, pressureless sintering of SiC for your life and property security escort

medium | content | Causticity | |||||||

Atmospheric SIC | The reaction SIC WC | WC | AL2O3 | ZrO2 | Si3N4 | stainless steel | steel | ||

HNO3 nitric acid | 50% | A | A | C | A | A | C | C | C |

Hydrochloric acid HCI | 35% | A | A | C | A | A | C | C | A |

Sulfuric acid H2SO4 | 98% | A | A | C | A | A | C | C | A |

Hydrofluoric acid HFF | 40% | A | C | C | C | C | C | C | C |

Phosphoric acid H5PO4 215OC | 85% | C | C | C | C | C | C | C | C |

HNO3+HF | 20%+5% | A | C | C | C | C | C | C | C |

Sodium chlorate NaCIO | 10% | A | B | C | A | A | A | C | A |

Sodium hydroxide NaOHH | 50% | A | C | A | B | A | B | A | A |

Potassium hydroxide KOH | A | C | A | B | A | B | A | A | |

Acetic acid CH3COOHH | 80% | A | A | C | A | A | C | C | C |

Sodium sulfate + Na2CO3 + H2SO4 925OC

| A | A | C | A | A | C | C | B | |

Silica solution SIO2

| B | C | C | C | C | C | |||

Assessment Method: the specimen prior polishing, immersed in the test liquid (70OC) for 100 hours, the weight was measured and observed microstructure, weight reduction is calculated by the degree of corrosion was observed microstructure for corrosion to comprehensive judgments. | |||||||||

A level (corrosion): corrosion rate ≤0.125mm / ingredients in a small amount of corrosion observed slice | |||||||||

Level B (somewhat resistant): corrosion rate = 0.125-1.0mm / or annual corrosion rate ≤0.125mm / observe a large number of corrosion | |||||||||

Class C (resistant to corrosion): corrosion rate ≥1.0mm / or the main ingredient of Corrosion

Silicon carbide performance indicators

Index Name

| Atmospheric SiC | Reaction Bonded Silicon Carbide |

Purity (%) of silicon carbide | > 97 | >90 |

Density (g / cm) | 3.06-3.15 | >3.05 |

Particle size (um) | 0.5-0.7 | 8-20 |

Hardness (HRA) | ≥90 | ≥90 |

Flexural Strength (MPa) | 400-580 | 350-450 |

Compressive strength (MPa) | 3900 | >2500 |

Fracture Strength (MPa) | 3.05-4.6 | 4.3 |

Elastic Modulus (GPa) | 380-410 | 420 |

Thermal conductivity | 102.6 | 35-110 |

Coefficient of thermal expansion (1 / ℃) | 4.02×10 | 4.3×10 |

Poisson's ratio | 0.14 | 0.15 |

- Q: What kinds of seals are there in SKF bearings?

- The so-called bearing additional sealing performance device, that is, in the installation of end caps and other internal manufacturing into a variety of sealing devices.The following main factors should be taken into account in the selection of bearings for external seals:1. bearings, lubricants and types (greases and lubricants);2. the working environment of the bearing, the size of the occupied space;

- Q: Replacement seals, but it does not feel like a O ring, ask this solenoid valve seals what is the name, specifications how to express?

- Noise reduction and decompression of the seat, and therefore used for flashing and other industrial and mining, the drawback is that the media can not be used for dirty areas.V- ball and eccentric rotary valve can be used in slurry and other impurities containing medium.

- Q: What are the main seals used in nuclear power plants?

- Similar to thermal power plants or petrochemical plants.Seal depends on the equipment, in addition to nuclear island equipment, nuclear power and thermal power. Nuclear island equipment seals are also more than a radiation protection requirements.

- Q: What kind of seal is the dust sealing ring?

- Role of dust ringDust seal is very important for the protection of some hydraulic equipment. If the hydraulic equipment into a number of dust, not only will wear to the seal, but also for some guide sleeve and piston rod wear is more serious. In addition, if these impurities into the hydraulic medium, the operation of the valve will also have a certain impact on the pump function, and if the situation is worse, a lot of damage to these devices may. After using the dustproof ring, the dust and sundries of the wheat on the piston rod can be effectively removed, but the oil film on the upper part can not hurt any more, and is beneficial to the lubrication of the sealing element.

- Q: How can the tapered roller bearings be sealed?

- There are many kinds of tapered roller bearings, I wonder if it is oil lubrication or grease lubrication? Dustproof or anti leakage?

- Q: How to prevent the metal from sticking to the gasket?

- It is better to use torque wrench when sealing gasket is pressed. For large bolts and high strength bolts, it is better to use hydraulic tightening devices. The tightening torque shall be calculated by calculation according to the given gasket. The size of the hydraulic pressure of the hydraulic tightening device shall also be determined by calculation.5. When installing the gasket, tighten the nut in sequence. However, the design value should not be screwed once. Generally should be recycled at least 2~3 times so that the gasket can be evenly distributed.6, the flammable and explosive medium pressure vessel and piping, replacing gasket should be used to avoid security tools, tool and flange bolts or collide, sparks, causing a fire or explosion accident.

- Q: The material of the seal must be compatible with the medium in contact with it. Why? What is compatibility? Thank you

- For example, three Yuan rubber sealing material is good, can withstand a certain corrosive acid, so it can be used to seal the acidic decomposition medium such as high voltage gas insulated SF6, but if used to seal the aviation hydraulic oil will fail because of three EPDM not resistant to oil, then we must choose nitrile rubber.

- Q: What is the sealing principle of O type sealing ring?

- Type O sealing ring is a sealing extrusion type, the basic working principle of extrusion type seal is the seal on elastic deformation caused by contact pressure in the sealing contact surface, the contact pressure is greater than the sealed medium pressure, no leakage, and leakage.

- Q: How do you determine the assembly direction of the cylinder seals?

- Look at your choice of sealed form, two-way sealing products do not have to consider the direction of installation, but some lip products, such as Y ring, we should consider the direction of the lip and the direction of the oil pressure coordination

- Q: What is the maximum resistance to the seal in the hydraulic system currently being produced?

- Therefore, in order to improve the sealing capacity, not only rely on seals, good structure is also very important. You say, if the light takes into consideration the seal, there is no problem with the regular 50MPa (usually around 30).

Send your message to us

SSIC Silicon carbide tube

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 pc

- Supply Capability:

- 500 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches