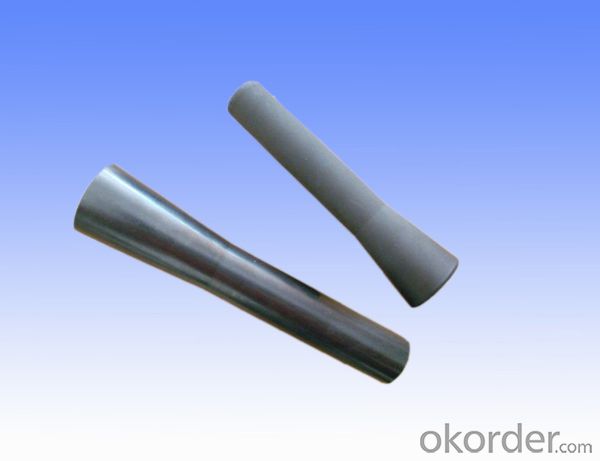

SSIC Axle sleeve

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

|

Tailor-made for customers all kinds of pumps with my company, kettle, bearing no pressure sintering silicon carbide mechanical seal, and all kinds of resistance corrosion pump parts and the accessories. Our company pressureless sintered silicon carbide products a reaction bonded silicon carbide products, can easily adapt to the harsh working conditions, in strong corrosive, strong wear, high temperature, high pressure, high strength harsh harsh under complex conditions is more outstanding. At the same time, our company to provide customers with nozzles, armored body armor plate and other special-shaped pieces of custom-made service. Compared with the reaction sintered silicon carbide product (SSIC), the production process of the sintered silicon carbide product (RBSIC) is complex and the production investment is high. In addition, whether it is in the resistance to corrosion and abrasion, compressive and flexural fracture resistance of or high pressure, high temperature and other properties are more excellent, this is pressureless sintering silicon carbide products will in the near future completely replace reaction bonded silicon carbide products is one of the important reasons. The main varieties of the pressureless sintering silicon carbide products with all kinds of mechanical seal with sealing ring and moving ring and static ring, corrosion resistant pump, magnetic pump, shield pump components. At the same time, the production special-shaped pieces of nozzle, wire drawing die, armor plate. According to the drawings, we will provide customers with satisfactory products and customer satisfaction. Let customer satisfaction is one of the purposes of our company has been pursued, but also one of the objectives pursued by all the staff of our company. Features: high temperature resistance, wear resistance, corrosion resistance, oxidation resistance, hardness, heat conduction Main products: mechanical seals, pump parts, nozzles, bullet proof plate Mechanical seals: high hardness, high wear resistance, good self - Lubrication and high heat conductivity, so the service life of mechanical seal is greatly improved. Pump: resistance to corrosion and wear characteristic of the pressureless sintering silicon carbide become magnetic pump sliding bearing, resistant corrosion pump sleeve, shielding pump assembly, etc. various kinds of pump of choice Nozzle: wear resistant, high temperature resistance, high hardness characteristics of the normal pressure sintering silicon carbide nozzle to become a perfect alternative to carbide nozzle Armor: light weight, high hardness, good ballistic performance, pressureless sintering of SiC for your life and property security escort |

Here are some of the pressure sintered silicon carbide products, physical and chemical parameters:

medium | content | Causticity | |||||||

Atmospheric SIC | The reaction SIC WC | WC | AL2O3 | ZrO2 | Si3N4 | stainless steel | steel | ||

HNO3 nitric acid | 50% | A | A | C | A | A | C | C | C |

Hydrochloric acid HCI | 35% | A | A | C | A | A | C | C | A |

Sulfuric acid H2SO4 | 98% | A | A | C | A | A | C | C | A |

Hydrofluoric acid HFF | 40% | A | C | C | C | C | C | C | C |

Phosphoric acid H5PO4 215OC | 85% | C | C | C | C | C | C | C | C |

HNO3+HF | 20%+5% | A | C | C | C | C | C | C | C |

Sodium chlorate NaCIO | 10% | A | B | C | A | A | A | C | A |

Sodium hydroxide NaOHH | 50% | A | C | A | B | A | B | A | A |

Potassium hydroxide KOH | A | C | A | B | A | B | A | A | |

Acetic acid CH3COOHH | 80% | A | A | C | A | A | C | C | C |

Sodium sulfate + Na2CO3 + H2SO4 925OC

| A | A | C | A | A | C | C | B | |

Silica solution SIO2

| B | C | C | C | C | C | |||

Assessment Method: the specimen prior polishing, immersed in the test liquid (70OC) for 100 hours, the weight was measured and observed microstructure, weight reduction is calculated by the degree of corrosion was observed microstructure for corrosion to comprehensive judgments. | |||||||||

A level (corrosion): corrosion rate ≤0.125mm / ingredients in a small amount of corrosion observed slice | |||||||||

Level B (somewhat resistant): corrosion rate = 0.125-1.0mm / or annual corrosion rate ≤0.125mm / observe a large number of corrosion | |||||||||

Class C (resistant to corrosion): corrosion rate ≥1.0mm / or the main ingredient of Corrosion

Silicon carbide performance indicators

Index Name

| Atmospheric SiC | Reaction Bonded Silicon Carbide |

Purity (%) of silicon carbide | > 97 | >90 |

Density (g / cm) | 3.06-3.15 | >3.05 |

Particle size (um) | 0.5-0.7 | 8-20 |

Hardness (HRA) | ≥90 | ≥90 |

Flexural Strength (MPa) | 400-580 | 350-450 |

Compressive strength (MPa) | 3900 | >2500 |

Fracture Strength (MPa) | 3.05-4.6 | 4.3 |

Elastic Modulus (GPa) | 380-410 | 420 |

Thermal conductivity | 102.6 | 35-110 |

Coefficient of thermal expansion (1 / ℃) | 4.02×10 | 4.3×10 |

Poisson's ratio | 0.14 | 0.15 |

- Q: What are the differences between the major and minor axes of a car?

- The length is determined, the wheelbase is the most important influencing factors of space travel, because the 2 car passenger seats accounted for most of the 3 passenger cars and car are arranged between the front and rear axles. The long wheelbase increases the longitudinal space of the occupant, greatly increasing the foot space that influences the riding comfort of the vehicle. Although the wheelbase is not the only factor in determining the vehicle space, but it is the fundamental factor. The car with short wheelbase can't be compensated for by some design, but it is still limited in general

- Q: When you mark the axis number, it indicates that the selected axis is not the starting axis. It can not be continuously marked with the axis number

- There are several possible causes of this:1, the axis is not automatically generated line segments, but hand-painted multi paragraph line, format brush can change other attributes, but can not change the multi line into the axis, the default line format, so the day can not read.

- Q: The transmission change ratio is defined as the input shaft speed / output shaft speed. So, is the 1 gear drive larger than the 5 gear transmission ratio?

- Split view should be control relationship between the gearbox and the speed of the engine, the clutch control left after incision impact of transmission speed has been in decline, because of the transmission loss from the driving force of the engine after the body inertia driving tire with gear rotation. The right pedal is actually controlling the speed of the engine.

- Q: What is the heat treatment method for making the shaft made of 45 steel? What is the microstructure after heat treatment?

- The method of heat treatment after quenching and tempering at high temperature is called quenching and tempering. High temperature tempering means tempering between 500-650 degrees centigrade. Quenching and tempering can make the properties and material of steel be adjusted greatly. The strength, plasticity and toughness of the steel are better, and it has good comprehensive mechanical properties. The tempered bainite is obtained after quenching and tempering.

- Q: How does the plane move along the Z axis in SketchUp?

- First select the plane, then move it to the blue axis using the moving toolOne, in general, when the moving direction tends to the blue axis, the blue auxiliary line appearsAt this point, the shift can lock the blue axis so that the plane moves along the blue axis

- Q: What are the differences between axial and oblique strikes of hydraulic generators?

- . The higher the head drop, the greater the power required to meet the requirements of the pipe. This form can be divided into new and old and new turgo "double double turgo", "four ring pipe spray turgo", according to the change of water source, adjust the number of switching nozzle, make better use of water resources.

- Q: What does axle control and frame control of locomotive mean?

- Many so-called axis controls are only inverters that independently control a motor, and the previous rectifier or intermediate loop is still common to several motors.

- Q: What does DNF's Y axis move and the X axis shift mean?

- SS Y mobile weapons shaft speed, can be in there for the Gelansidi!

- Q: What are the differences between the temperature instrument, axial type and universal type, radial type?

- The axial type is also called angle type, radial type is called straight shape and universal type is called adjustable angle shape. The specific shape is as follows:

- Q: What is the driving shaft in the conveyor and what is the passive shaft? I hope friends can give me a detailed answer! Thank you

- The active shaft and the passive shaft should be a pair of directly adjacent shafts connected by transmission (gears, pulleys, sprockets). Which axis is near to the power source, which is called the driving shaft, but the one near the working axis...............

Send your message to us

SSIC Axle sleeve

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot Searches