Specifications Complete Used Pump Rod Straightening Machine

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. The applications structure and characteristics

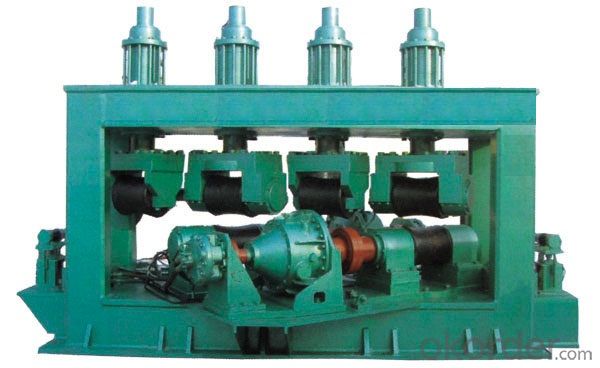

Pump rod straightening machine is an rotary pump rod straightening equipment. It is applicable to Φ16-Φ40 pump rods.

The characteristic of this machine include advanced structure, which uses cross rolls straightening. It is a seven-roll machine. It is made up of upper four rolls(three hosts and one back) and lower three rolls (two host and one back).

The upper four rolls are controlled by the oil cylinder.The fine control can clamp. The lower two drive rolls can be drived by variable speed hydraulic motor with the reduction box(including the upper three drive rolls ). Straighten the rods well, high efficiency, good quality, low residual stress, high straightness accuracy.

2. Technical requirement

Applicable diameter: Φ16-Φ40mm

Applicable length: 4-10m

Straightening straightness: ≤50 mm/m

Straightening precision: ≤2 mm/m

System pressure:15Mpa

Straightening speed: 0.2-0.7m/s

Total power of equipment(kw): 30KW

3. Principle and Structure

1) Principle

There are two rows(upper and lower) crisscross arrangement working rolls on the roller type straightening machines. The crooked rod between the rotating work rolls does the rectilinear motion. After the work rolls bend several times, the rod appears elasto plastic deformation and is straightened.

2) Structure

The machine is made up of a frame and a upper roll subsystem, a upper roll angular adjustment mechanism, a lower roll subsystem, a lower roll angular adjustment mechanism, a upper roll gap combination oil cylinder, a hydraulic system, a control console, a electrical system and so on.

1) The frame adopts the frameset structure. It consists of a underpart(a base), a column, a upperpart and so on. Except the hydraulic system, other components installed in the frame.

2) The upper and lower roll subsystems are segmented into the drive roll and the passive roll. Except the hitch bar and the drive motor, the dirve roll are the same with the passive roll. Those are the arbour, the bearing, the bearing seat and so on.

3) The upper four angular adjustment mechanism are adjusted by the frameset mechanism uniformly. The lower three rolls are adjusted separately. It is made up of multi-stage screw rods, nuts, cutter axis, a support and so on.

4) The upper roll gap combination oil cylinder consist of the oil cylinder, the valve guide disc guide, the worm wheel, the worm mechanisms, screw rods,the hand wheel and so on. It can adjust the distance between the upper and lower rolls.

5) The rapid up-and-down system are fixed on the host.It is controlled by the oil cylinder.

4. The hydraulic unit (the hydraulic system and the process flow-path)

The hydraulic unit single device is made up of a electrical motor, a hydrulic pump, a oil cylinder, a integrated package, various hydraulic valves, a cooling apparatus and so on. It is the power souce. The hydraulic valves use subbase mounting wholly. They are fixed on the integrated package directly, beauty, dependable performance, convenience of installation, debugging, maintenance.

1) The power source is a 30KW motor(collocation P=17.5,a vane pump of displacement 153).

In the system, it use one pump distributary two circuit feeding and passing hydraulic loop. It is made up of one main integrated package and four branch integrated packages, which form two units partly. That will optimize pipeline configuration, reduce oil return resistance between the system, lower hydraulic drive interference. In the system if the motor leaks the oil, it will intensively recycle into the oil cylinder.

2. In the system instruction unit ,the electrical cabinet carry out the instruction repertoire.

In the conrolling unit, the electromagnetic relief valve, the slenoid valve, the NDV/NDRV form together the contorlling programme. In the execution unit, the hydraulic oil cylinder, the hydraulic motor form the execution programme.

- Q: What are the platinum metal processing equipment?

- Platinum metal processing equipment: ultrasonic cleaning machine, all kinds of files, polishing machine, welding equipment, electroplating, mould, hammer and so on.

- Q: What do metal processing machines include?

- Automation machinery: automation tools, bearings, cleaning machines, mechanical drive systems, automatic control systems, packaging equipment;

Send your message to us

Specifications Complete Used Pump Rod Straightening Machine

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords