SPC-K03H Automatic High Speed Carton Erector

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 10 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Features

1.Precision designed and engineered by expertise. This carton erector has been awarded several patents, and has received approval from famous industries around the world. It is the highest speed carton forming and sealing machine in Taiwan.

2.Fully cam driven continuous system assures positive and stable motion with maximum stability.

3.In a breakthrough for tapping head design, this machine provides extremely secure sealing effect, outstanding tape smoothening performance, without tape slipping problems.

4.Accommodates all type of self-adhesive tapes.

5.Variable speed adjustment for carton forming and sealing. Reducing labor requirements.

6.Easy to operate and adjust. No damage on carton.

7.Horizontal cardboard stacking permits for supply of empty carboard at any time.

8.Automatic indication for tape replacement or cardboard supply.

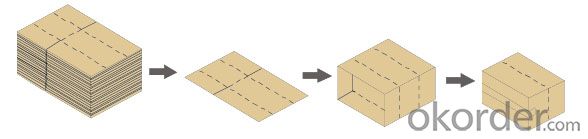

Work Flow Chart

SPC-2500 | Technical Parameters | ||

Model | SPC-K03H40 | SPC-K03H20 | SPC-K03H10 |

Forming and Sealing Speed | 40(cartons)/min | 20(cartons)/min | 10(cartons)/min |

Carton Storage Quantity | 70pcs(700mm) | 100pcs(1000mm) | 50pcs(1000mm) |

Carton Sizes(mm) | L:280-500*W:200-400*H:200-400mm | L:280-500*W:200-400*H:90-400mm | L:200-450*W:150-400*H:100-350mm |

Power Requirements | 750W(AC380V 3F ) | 750W(AC380V 3F ) | 750W(AC380V 3F ) |

Air Compressing | 4~5kg/cm2 | 4~5kg/cm2 | 5~6kg/cm2 |

Air Consumption | 450NL/min | 450NL/min | 150NL/min |

External Sizes | L3540*W1250*H1840mm | L2780*W1250*H1840mm | L2000*W1900*H1200mm |

Machine Weight | 990 kgs | 990 kgs | 350 kgs |

Applicable Tape Size | 1 1/2", 2", 2/12", 3" | 1 1/2", 2", 2/12", 3" | 1 1/2", 2", 2/12", 3" |

- Q: What is the design basis of automated packaging?! Just for today!

- Increase productivity and reduce process costGerman packaging machinery, especially beverages, beer filling machinery and food packaging machinery, with high speed, complete sets, high degree of automation and good reliability and so on. Beverage filling speed up to 1200 bottles / D, when the cigarette packaging 12000 / min.. Increasing the speed of the machine is a complex problem. The faster the piece production cost is, the higher the use area of the workshop is. In addition, the speed of the motor is limited, so do not think how fast, how fast. In general, the speed increase by 15%, 20%, will lead to a series of complex problems. In addition to increasing the speed, the productivity can be solved from other channels:1. continuous or long work. Packaging machinery works a batch type and continuous type, design, design should strive for continuous work, also can improve the productivity; one device may also have multiple production lines, the production of the same product or several different products, but must improve the reliability.2. reduce scrap rate and provide fault analysis system. The loss of waste to production is enormous, not only product loss, but also material loss. So try to force to reduce the rejection rate; packaging machinery sale should also provide maintenance services for the fault analysis system, the modal analysis is carried out to find fault, or through the Inter network for remote diagnosis, the maximum to meet customer needs. In the future, the packaging machinery will be further intelligent, that is, the equipment itself to find fault, to solve their own failure, to reduce waste rate and failure rate, so that the normal productivity can be improved.

- Q: What is the general packing cost of beer beverage packaging?

- In addition, according to the product's own conditions to set, the packaging machine prices are generally in the range of 3-5 yuan

- Q: What is the price of a small jujube packing machine?

- Small packaging machine is mainly divided into single grain and multi grain packaging, there are 3-6, there are about 200000. Mainly depends on the performance and use of the machine

- Q: What kind of reducer is commonly used in packaging machinery?

- There are many kinds of packing equipment, such as food packing, filling, quantitative packing, back channel packing and so on

- Q: Working principle of packing machine

- The working principle of the packing machine is simple. The packing material is first installed on the packing machine and installed

- Q: Food packaging process is not standardized, there is no responsibility?! For example, after the production of candy, because there is no corresponding packaging equipment, the need for artificial packaging

- Yes, automatic packing machine. I'm an employee of the automatic packaging machinery company.

- Q: What is the delay time of the packer's cross sealing?

- There is also a delay in the end of the last movement of the machine to the beginning of the sealing action.

- Q: Food, equipment, tools, containers, packaging materials, etc. shall comply with food safety standards or requirements

- Hygienic standard for polyethylene terephthalate resin for GB 13114 food containers and packaging materialsGB, 13113-1991. Hygienic standard for polyethylene terephthalate molded articles for food containers and packaging materials

- Q: Will the Internet be too passive? Telephone marketing, what kind of food can be found in the factory, such as the phone, people basically do not need, and all have. Does the salesman run the market? How do you run? Thanks for the direction...

- Mechanical sales are nothing more than two points: first, equipment aging, need to update; two, equipment efficiency is low, need to improve. You don't know anything about the customer. Come up and sell the product. If you are a customer, I don't think you have the patience to listen

- Q: Calendering, extrusion, blow molding, pressing, plastic (vacuum forming) and what is the rotational molding

- Plastic forming and processing methodPlastic molding is an engineering technology, involves the plastic into all kinds of plastic products in the process. The transformation process tends to happen in one or more of the following conditions, such as polymer rheology and physical and chemical properties of the change.

Send your message to us

SPC-K03H Automatic High Speed Carton Erector

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 10 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords