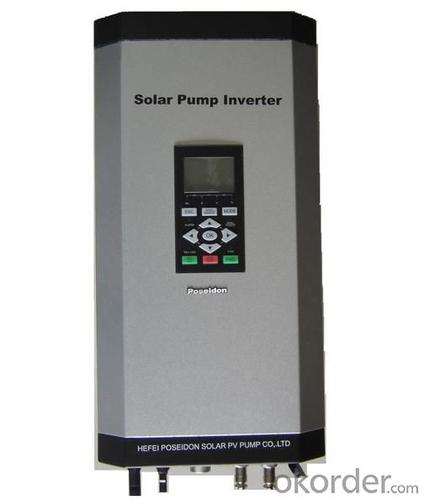

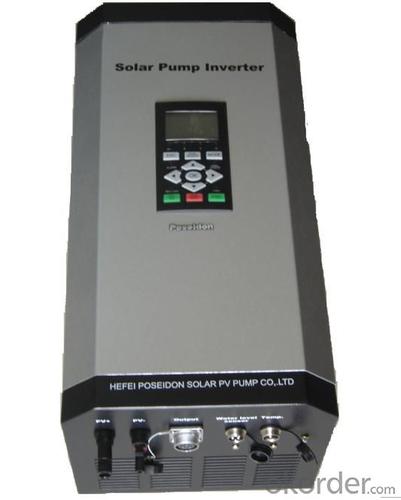

RPS 400 Solar Pump FCPM11KH Inverter

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Solar pump inverter FCPM11KH Product Description:

Solar water pumping system is constructed with solar panel array,solar pump inverter and AC water pump, DC current produced from solar panel will be delivered to solar pump inverter,and it will convert it into AC current to drive water pump,and will automatically regulate output frequency according to sun radiance intensity,maximally realize MPPT tracking function.

Features

Adopting the proposed dynamic VI maximum power point tracking (MPPT) control method, with fast response, and reliable operation, achieves efficiency of 99%.

Designed with variable frequency driver, greatly improves efficiency

Extremely high efficiency

Digital mode control, with automatic operation and manual operation mode options

Complete protection functions

Adopts intelligent IPM module, with high reliability

LCD display and operation panel, in real time presents operating data

Optional for water level measurement and control circuit

Applicable for general ACC pumps, like centrifugal pump, piston pump etc.

Independent intellectual property; Highly effective, the redundant reliability, exempts the maintenance and the long life.

The pumps are soft started, fully protected.

No batteries are used. So better Sunlight, more water.

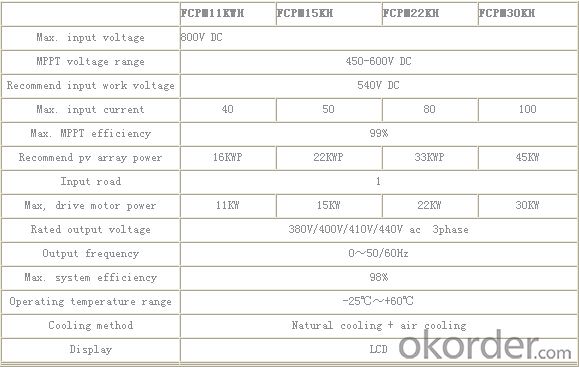

Datasheet.

- Q: What is the maximum pressure that a solar pump can generate?

- The maximum pressure that a solar pump can generate depends on various factors such as the type and size of the pump, the amount of sunlight available, and the specific design specifications. However, in general, solar pumps can typically generate pressures ranging from 30 to 100 pounds per square inch (psi).

- Q: Are solar pumps weatherproof?

- Solar pumps are indeed weatherproof. They have been engineered to endure diverse weather conditions, such as rain, snow, and extreme temperatures. Typically, they are constructed using sturdy materials that resist corrosion and UV radiation. Moreover, they often come with protective covers or casings to safeguard the internal components against moisture and other environmental elements. This impeccable weatherproof design guarantees the efficient and dependable operation of solar pumps in any outdoor environment, making them ideal for a variety of uses, such as irrigation, water supply, and fountain systems.

- Q: Can a solar pump be used for water circulation in ponds or lakes?

- Yes, a solar pump can be used for water circulation in ponds or lakes. Solar pumps are designed to operate using sunlight, converting it into energy to power the pump. They are often used in outdoor settings, including ponds and lakes, to circulate and aerate the water. This not only helps maintain water quality but also prevents stagnation and promotes a healthier environment for aquatic life.

- Q: What is the cost of a solar pump?

- The cost of a solar pump can vary depending on several factors such as the brand, capacity, and features. On average, a basic solar pump for small-scale applications can cost anywhere between $500 to $2,000. These pumps are typically used for irrigation purposes in gardens or small farms. For larger-scale agricultural or commercial applications, the cost can range from $2,000 to $10,000 or more, depending on the size and capacity of the pump. These pumps are designed to handle higher volumes of water and may have additional features like remote monitoring or advanced control systems. Furthermore, the cost may also include additional components like solar panels, batteries, and installation charges. It is important to consider the overall system requirements and consult with a reputable supplier or installer to get an accurate estimate of the total cost. It is worth noting that while the initial cost of a solar pump may be higher compared to traditional pumps, the long-term benefits, such as reduced energy costs and environmental sustainability, make it a worthwhile investment in the long run.

- Q: Can a solar pump be used for water circulation in fountains or decorative features?

- Yes, a solar pump can be used for water circulation in fountains or decorative features. Solar pumps are specifically designed to operate using solar energy, making them a sustainable and eco-friendly option for powering water features. They can effectively circulate water, creating beautiful and mesmerizing displays in fountains or decorative features without the need for electricity or traditional pumps.

- Q: What is the efficiency of a solar pump?

- The efficiency of a solar pump refers to how effectively it converts solar energy into pumping power. It is typically measured as the ratio of the pump's output power to the input solar power. Higher efficiency means that the pump can deliver more water or fluid using less solar energy, resulting in reduced operating costs and environmental impact.

- Q: Can a solar pump be used for water supply in recreational facilities?

- Certainly! Solar pumps have the potential to serve as a water supply solution in recreational establishments. These pumps offer an outstanding alternative to conventional electric or diesel pumps since they harness solar energy to generate power. In addition to being cost-effective and eco-friendly, solar pumps can reliably provide water to various recreational facilities, including swimming pools, water parks, and sports fields. By effectively extracting water from wells, rivers, or other water sources and distributing it to the desired location, solar pumps prove to be an efficient choice. Their installation is hassle-free, and they require minimal maintenance, making them an optimal choice for water supply in recreational areas. Furthermore, solar pumps can be equipped with storage systems to ensure a constant water supply, even during cloudy days or at night. In summary, incorporating solar pumps for water supply in recreational facilities not only reduces operating expenses but also showcases a dedication to sustainable and clean energy solutions.

- Q: How do solar pumps compare to diesel or electric pumps in terms of efficiency?

- Solar pumps are highly efficient compared to diesel or electric pumps. Solar pumps utilize energy from the sun, making them cost-effective and environmentally friendly. They have lower operating costs, as they do not require fuel or electricity from the grid. Additionally, solar pumps have a longer lifespan and require less maintenance, resulting in higher overall efficiency.

- Q: Can a solar pump be used in areas with high humidity?

- Yes, a solar pump can be used in areas with high humidity. High humidity does not affect the functionality or performance of a solar pump as it primarily relies on sunlight to generate power. However, it is important to ensure the pump's electrical components are properly waterproofed to prevent any damage caused by moisture.

- Q: Can a solar pump work at night or in cloudy weather?

- No, a solar pump cannot work at night or in cloudy weather as it relies on sunlight to generate the necessary energy for operation.

Send your message to us

RPS 400 Solar Pump FCPM11KH Inverter

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords