Solar Energy - Best Quality Flexible Solar Cells with CE, RoHS, ICE Certification

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 500 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Model Number: | ANM250M-96 | ||||

| Material: | Monocrystalline Silicon | Size: | 1575*1082*50 | Number of Cells: | 250 |

| Max. Power: | 250 | Certificate: | CE, ROHS, ICE | Warranty: | 5 years |

| keywords: | flexible solar cell | Short circuit current(Isc): | 5.95 | Open circuit voltage(Voc): | 58.40 |

| Current at max power(Imp): | 5.28 | Voltage at max power(Vmp): | 47.33 | Max. Power (Pm): | 250 |

| Operate Temp. scope: | -40~85 | Impact Resistance: | AC2000V; DC3000V |

Packaging & Delivery

| Packaging Detail: | standard export package suitable for long seavoyage and tough handling |

| Delivery Detail: | 10-25 days depending on order quantity |

Specifications

flexible solar cell

1.Monocrystalline

2.Solar Panel Factory

3.CE, ROHS, IEC

4. 5yrs warranty

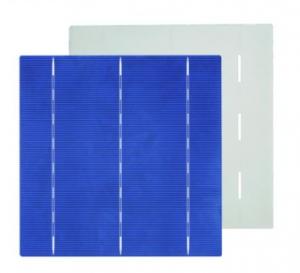

Types of Solar Cell

Current solar cells are classified into several types according to the material, structure and the manufacturing method used. Wherein the multi-crystalline silicon solar cell refers to the silicon semiconductor substrate is a monocrystalline silicon solar cells and a raw material polycrystalline silicon solar cells; in addition to amorphous silicon-based solar cells, such batteries with the liquid crystal panel prepared by the same film is based, it is deposited on a silicon substrate instead of a glass substrate made of amorphous silicon.

Monocrystalline silicon solar cells are formed on a monocrystalline silicon substrate, but also the conversion efficiency up to 20% of the products, with excellent performance and reliability characteristics. However, as the price of raw materials expensive silicon substrate, the higher cost of electricity per watt. Although polycrystalline silicon solar cell conversion efficiency is lower than that of silicon solar cells, with the advantage of cheap cost.

Most substrate monocrystalline and polycrystalline silicon solar cell used is from the slowly cooled liquefied silicon after heating the crystalline silicon block (ingot) cut out of the sheet manufacturing. Forming a polycrystalline silicon solar cell uses polycrystalline silicon ingots; forming a single crystal silicon solar cell uses single crystal silicon ingot. Compared with polysilicon ingot, single crystal silicon ingot production efficiency is lower, therefore more it is more expensive.

The more cutting thin silicon substrate, the silicon ingot obtained by the same base plate number, the more, the lower the cost. However, there are also disadvantages sheet cut easily broken during the manufacturing process. So how global materials manufacturers around the sheet during cutting and increase yield, reduce cost in a fierce competition.

Using a thin film of amorphous silicon solar cell production method is different significantly reduce the amount of silicon used, and vacuum evaporation using a manufacturing process suitable for mass production, as compared with the crystalline type can significantly reduce costs, but the amorphous silicon solar cell lower conversion efficiency is only about 10%. Such batteries silicon feedstock prices of the period of concern, but with the tight silicon market weaker than expected growth in its share.

- Q: What is the impact of extreme temperature fluctuations on solar cell efficiency?

- Extreme temperature fluctuations can have a significant impact on solar cell efficiency. When the temperature rises, solar cells tend to generate less electricity due to increased resistance and decreased voltage. Conversely, in colder temperatures, solar cells may experience higher efficiency initially, but this could be offset by reduced performance as the temperature drops even further. Therefore, extreme temperature fluctuations can lead to a decrease in overall solar cell efficiency, affecting their ability to harness and convert sunlight into usable electrical energy.

- Q: Can solar cells be used in smart grid systems?

- Yes, solar cells can definitely be used in smart grid systems. Solar cells can generate electricity from sunlight, which can then be integrated into the smart grid to efficiently distribute and manage renewable energy. This allows for the seamless integration of solar power into the grid, reducing reliance on conventional energy sources and promoting a more sustainable and reliable energy system.

- Q: Can solar cells be used for indoor applications?

- Yes, solar cells can be used for indoor applications. While solar cells are primarily designed to harness sunlight and convert it into electricity, they can also generate power from indoor lighting sources such as fluorescent or LED lights. However, the amount of electricity generated indoors is generally lower compared to outdoor conditions due to the reduced intensity of indoor lighting. Nonetheless, solar cells can still be used effectively for powering small devices or charging batteries in indoor settings.

- Q: Can a solar cell be used in commercial buildings?

- Yes, of course, it can .

- Q: What is the impact of solar cells on reducing water usage?

- Solar cells have a positive impact on reducing water usage as they generate electricity without requiring water for cooling, unlike traditional power plants. This helps conserve water resources and reduces the strain on water supplies, particularly in regions facing water scarcity.

- Q: My solar cells are broken, can I just buy one and replace it?

- No, you just can not do properly

- Q: How do solar cells impact wildlife?

- Solar cells have a minimal impact on wildlife compared to other forms of energy generation. While the installation and maintenance of solar panels can disrupt local habitats temporarily, once operational, solar cells do not produce air or water pollution, noise, or hazardous waste that could harm wildlife. Additionally, solar farms can provide valuable habitats for certain species, as the spaces between panels can be used for vegetation growth. Overall, solar cells are considered a much cleaner and safer energy option for wildlife compared to traditional fossil fuels.

- Q: Can solar cells be installed on curved surfaces?

- Yes, solar cells can be installed on curved surfaces. Flexible solar panels are designed to be bendable and can conform to curved surfaces, making them suitable for a variety of applications such as solar-powered vehicles, curved rooftops, and even wearable technology.

- Q: What is the impact of snow accumulation on solar cell performance?

- Snow accumulation can significantly reduce the performance of solar cells. The presence of snow on the surface of solar panels prevents sunlight from reaching the cells, thereby reducing their ability to generate electricity. Additionally, the weight of the snow can cause structural damage to the panels and potentially lead to their failure. Therefore, snow accumulation must be cleared promptly to ensure optimal solar cell performance.

- Q: Can solar cells be used to power homes?

- Yes, solar cells can be used to power homes. Solar panels, made up of multiple solar cells, convert sunlight into electricity that can be used to power household appliances and lighting. This renewable energy source can provide a sustainable and cost-effective solution for residential power needs.

Send your message to us

Solar Energy - Best Quality Flexible Solar Cells with CE, RoHS, ICE Certification

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 500 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords