Soft Touch Lamination Film from A Professional Manufacturer

- Loading Port:

- Xiamen

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 500 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Soft Touch Lamination Film Description:

Soft Touch Lamination Film is coated on books and magazine; catalogs; pictures; promotional materials; non-drying adhesive; paper bag; clothes lag.Blueprint document; outdoor advertisement; spray painting; post; digital print.Wedding photograph; photo album.Outside coating for wrapping box for food; medicine; cosmetic; gift; liquor, ect.

Soft Touch Lamination Film is widely used in food,medicine,cosmetics and other industries packaging, can also be used for printing,garland,adhesive sticker ,gold and silver carboard

2.Main Features of the Soft Touch Lamination Film:

Low chormatic aberration after lamination.

Easy to use, saving operating time.

No bubble, wrinkle or desquamate.

Glossier than traditional laminating films, keep for a long time and protect the printing color from changing.

None solvent pollution, keep the factory much safer an environment-friendly, health for the workers.

Suitable for ordinary hot laminating machine.

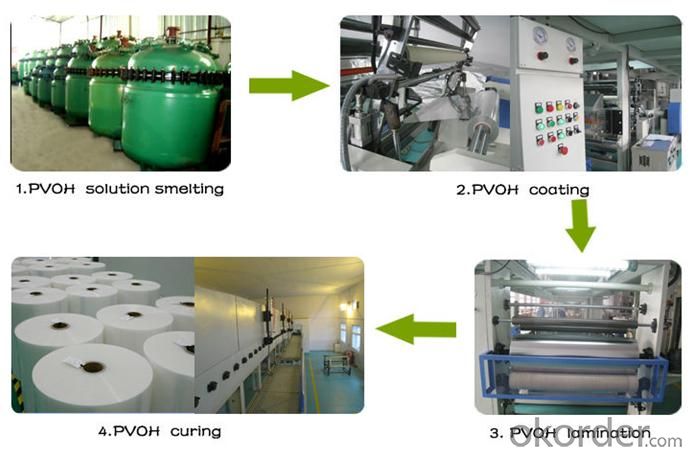

3. Soft Touch Lamination Film Images

4. Soft Touch Lamination Film Specification

Appearance ( color ) | : light white transparent liquid | |

2 | Solid content(NV%) | : 6.3±0.2% |

3 | Viscosity | :27s±2s |

4 | Diluent | : water |

washing solvent | ||

5 | Coating solution temp. | : normal temperature |

6 | Storage condition | : 5~30°C |

7 | WVTR result | :NOT AVAILABLE |

8 | O2TR result | :≤75px3/m2•24h•0.1MPa |

9 | Compatibilityand good bond coating with polyurethane adhesive | Enough |

: polyesther or polyether adhesive | ||

10 | Appearance after coating | : ( must brightly or clearly |

11 | Bonding strength between PET and PVA | ………………………………gr/15mm or N/15mm |

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

one of the largest thermal film manufactures in China. We are engaged in developing and producing new types of environmental friendly laminating materials(thermal laminating film for offset prints, digital prints and advertising inject prints).Our products are exported to Europe, North America, South America, South East Asia, etc.

②What is the package?

3 inch paper roll is always made with more than 1000 meters,so it is always packaging with one roll one carton.And 1 inch paper core is made with below 500meters,so we always packaging it with 9 rolls with one carton.and then by pallet.

③How to application manual?

.Adjust roller pressure and temperature according to different types of paper and ink.

.When using the film for the first time or changing to other sizes, we recommend a small trial volume before going into fully mass lamination.

.The following situation will affect the quality of the film during lamination.

a. When using metal ink

b. When the ink contains too much wax, dried oil, adhesive, and silicon additive. etc

c. When the ink is too thick

d. When the ink is not completely dry

e. When the paper contains too much moisture

f. When there is too much powder

- Q: The technical issues of the cutting PE protective film

- It's about the cutter. Maybe the position of cutter is too low. Sometimes, if the cutter ring is not smooth enough, the same problem may occur. Besides, for better result, you should also ensure that the cutter is pressed to the right position and no indentation on the blade.

- Q: Import PET protective film has those good introduction?

- Organic or inorganic glass lenses, various metal, electroplating plates, stainless steel, aluminum profiles, steel plastic profiles, aluminum plastic panels, glass panels, various types of paint panels, high-grade furniture, stone and other materials surface protection

- Q: What are the ways to remove the stainless steel protective film?

- 5. With hand cream. First, the surface of the printed products tear off, and then put some hand cream on the top, slowly rub with your thumb, rub for a while, you can rub the stainless steel protective film on the residual gum are rubbed down. Just slow down. Hand cream is a kind of grease, which is not compatible with gum. Remove glue is to use this characteristic.

- Q: What are the protective films?

- The most common is the high definition film, characterized by cheap, clear (relative to matte film, diamond film transmittance and reflective rate), the closest to the visual effect of no film, the drawback is easy to leave fingerprints, oilIt is a very good feeling, matte film, matte, not easy to leave fingerprints, to the maximum to avoid the disadvantages of the situation that HD phone screen patch of oil is the reflection rate is high, that is to increase the brightness of the screen, or see clearlyNail polish is similar to that of diamond films that the girls, similar to the feeling of the fluorescence is not easy to keep the fingerprint grease shortcomings and scrub, and the outside world is too bright that fluorescent (or reflective chips) will affect the mobile phone reading sight

- Q: The mirror protective film is what, how should the truth!

- The common protective film just scratch the most basic function, mirror protective film protective film is a functional OK8 brand launched the first one in the scratch with new technology, the mobile phone background lights off when the protective film provides the user with a mirror function, as well as anti spy film, matte film, AR film other types of protective film, LZ if you want to further understand can go to the OK8's official website. There is this brand of protective film, the price is similar to the highest inside the protective film

- Q: What are the main components of PE protective film?

- The main components of PE protective film are polyethylene thin film and acrylic glue. Basically, it does not contain substances that are harmful to human body after the production is done. Of cource, the premise is that it's properly used.

- Q: How should the PET protection film identify his viscosity?

- Usage: suitable for car color separation, industrial machine spray painting.Features 3: special PET, high temperature resistance, good adhesion, tensile strength, acid resistance, alkaline, impermeable, non residual glue.

- Q: What to do if the sandblasted protective film on marble stele is not adhesive any more?

- The reasons may be: 1. If there is oil or water on the surface of the processed stele, the film can't be sticked firmly. 2. Maybe the adhesion of the protective film is not enough. I suggest you try a new film that is more adhesive. We have recieved many similar complaints from our customers. Generally, we will provide them with a variety of protective films for testing.

- Q: Are PET silicone protective films the same for PE films?

- PET protective film for television screen, notebook computer screen, PDA handheld computer screen, LCD screen, PSP game machine LCD screen LCD screen, mobile phone, electronic dictionary, digital camera, camera screen, car DVD display, GPS LCD protection etc..

- Q: How to remove the protective film on PCM plate in a quick way?

- PCM plate can be coated with film using machine. But you can only tear off the film by hands. There is no such machine that can remove the film for you.

Send your message to us

Soft Touch Lamination Film from A Professional Manufacturer

- Loading Port:

- Xiamen

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 500 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords