Sodium Carboxymethyl Cellulose in Paper Making Good Emulsion

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 3000000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product description:

CMC is a high-efficiency paper-making auxiliary, and features good moisture retention, dispersibility. Pigment coating: CMC can help control and regulate the rheology of coatings and dispersibility of pigments, get pseudoplasticity of coatings, improve the moisture retention of coatings, has excellent film forming property; Intracytoplasm adding: improve jordaning efficiency, shorten pulping time, regulate electric potential of pulp, Improve the retention rate of additives, fillers etc; Top sizing: has excellent rheology and film forming property, improve the brightness and gloss of paper, Enhance the stiffness and smoothness of paper, Increase the surface strength and abrasion resistance of paper.

Specifications:

Product | Carboxyl methyl Cellulose ( CMC ) |

Main spec item | Degree of Substitution (D.S.) Viscosity |

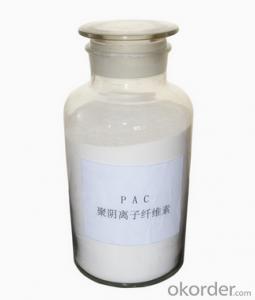

Color | White or yellowish |

Form | Powder |

Smell | Odorless |

toxicity | Non-toxic, Environmental friendly |

Packing | 25kg/bag |

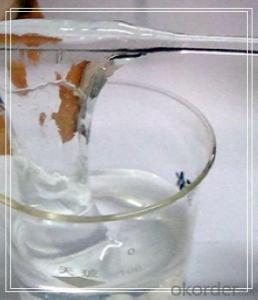

Solubility | When CMC dissolve in water, the liquid is transparent, which has good emulsion, dispersed, suspended and bonding role. Does not dissolve in acid, cresol, ethyl alcohol, acetone, chloroform, benzene and so on. Lightly dissolves in methyl alcohol, ether and so on such organic solvent |

Main feature:

CMC is used in making pulp so as to improve the retention rate and increase humidity and strength; when used in surface sizing, CMC can improve internal adhesion, decrease printing dust and enhance printing quality as molding reagent. In paper coating, CMC also helps the dispersion and fluidity of paint, improves appearance of paper and smoothness, upgrades optical performance and printing adaptability.

Packaging:

1. 25kg kraft bags with PE inner

2. According to the requests of the customers

FAQ:

1.Are you a trading company or manufacturer ?

We are direct manufacturer.

2.Why do we choose you ?

Advanced technology and facilities, good quality control, different grades for different applicaiton fields.

Send your message to us

Sodium Carboxymethyl Cellulose in Paper Making Good Emulsion

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 3000000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords