Functional Refractory Materials - Slide Nozzle Bricks and Converter Skimming System

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Slide Nozzle Bricks And Converter Skimming System

1、Slide Nozzle Bricks

In order to satisfy the requirements of various steels and working conditionns ,series slide nozzles including alumina-zirconia-carbon,alumina-carbon,and magnesia nozzles are prepared using high quality corundum, zirconia-corundum, magnesite,alumina micropowder,and graphite as raw materials,mixing, high pressure shaping,low temperature heat treatment,high temperature firing,and fine processing.The nozzles are featured with high strength,good corrosion and erosion resistance.

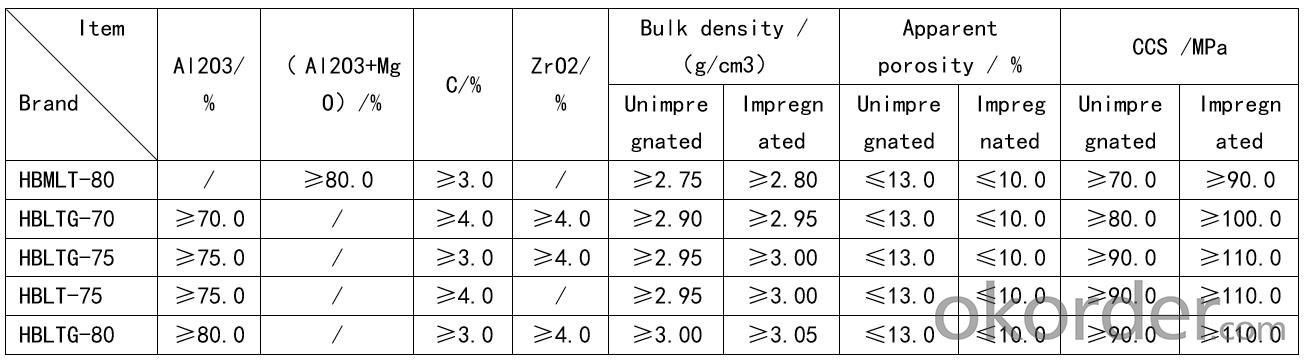

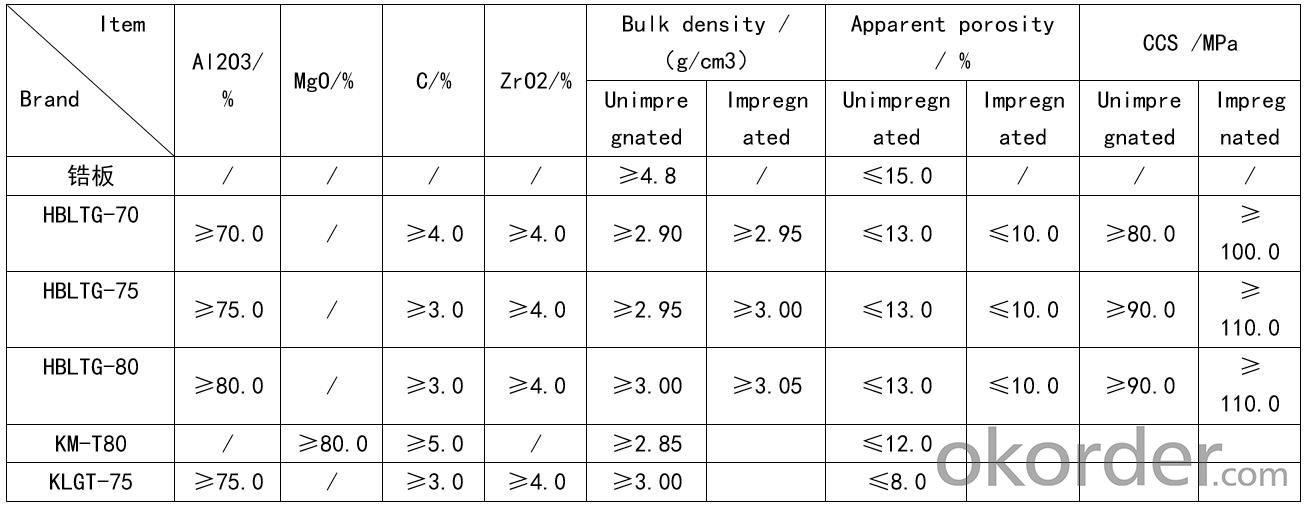

Physical properties and chemical composition of slide plate

Physical properties and chemical composition of nozzles

2、Converter Skimming System

According to the working mechanism of ladle sliding nozzle, the converter slide plate slag skimming technology is to install sliding taphole system at the end of converter taphole, and to control the sliding taphold system (open or close) by means of automatic slag-tapping detection system. The slide plate slag skimming technology of converter can avoid slag-tapping before steel-tapping, achieve fast, reliable and accurate slag-skimming in the later stage of steel-tapping, realize less slag and slag-free steel-tapping, reduce the slag-tapping amount of converter, reduce the consumption of deoxidizer and alloy, and increase the grade precision of molten steel and the yield of alloy.

As a key functional material to control the flow of converter molten steel, the slag skimming plate of converter has a decisive influence on the efficiency and safety of steelmaking process. It has to be subjected to harsh service conditions, such as long-term erosion and chemical corrosion of molten steel at high temperatures, and the thermal shock caused by repeated cycles between ambient temperature and service temperature.

In order to meet the requirements of various smelting conditions and different types of steel, our company has developed a series of slide plates and matching inner and outside nozzle bricks, such as alumina-zirconia-carbon, magnesia-carbon, zirconia plate (ring) composites, which have been well used in more than 60 converters with capacity of 70-350 tons in China and overseas.

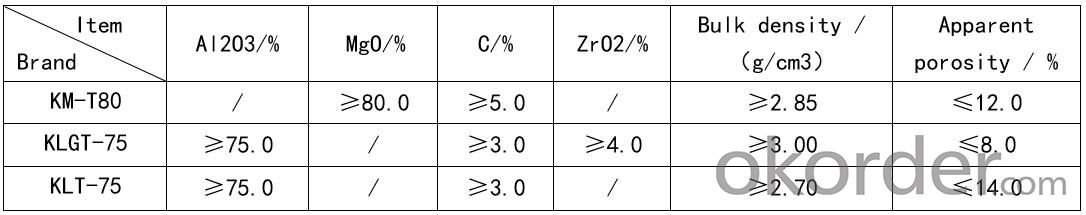

Physical properties and chemical composition of Slide plates and nozzle bricks for converter skimming system

Send your message to us

Functional Refractory Materials - Slide Nozzle Bricks and Converter Skimming System

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Ruitai Ma Steel New Materials & Technology Co., Ltd.

Ruitai Ma Steel New Materials & Technology Co., Ltd.