Sillimanite Brick - High Quality Sillimanite Bricks

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

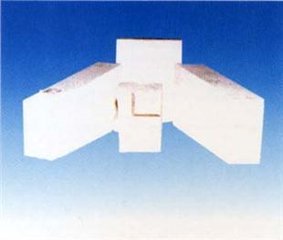

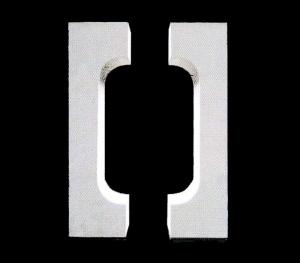

Refractory brick made of sillimanite minerals.Sillimanite into after high temperature calcination mullite and free silica.Commonly used high

temperature burning method and mud casting method.The physical and chemical performance is better than high alumina brick, 1770 ~ 1830 ℃,

refractoriness under load softening the starting point of 1500 ~ 1650 ℃.It is mainly used for glass tank furnace discharge hole forming,

blast furnace lining, furnace throat and ceramic industry kiln furniture.

Crystalline silicon steel gray, amorphous silicon is black, 2.4 g/cm3 density, melting point 1414 ℃, boiling point 2355 ℃, crystalline silicon atomic

crystal, hard and glossy, semiconductor properties.Silicon structure are similar to diamond, is a regular tetrahedron structure.Silicon chemistry

more lively, can at high temperature and oxygen etc. Various elements combined, insoluble in water, hydrochloric acid and nitric acid, soluble in

hydrofluoric acid and alkali, used to build alloy such as ferrosilicon, silicon steel, silicon single crystal is a kind of important semiconductor materials,

used in the manufacture of high power transistor, rectifier, solar cells, etc.Silicon is widespread in nature, containing about 27.6% of the earth's crust,

mainly exists in the form of silica and silicates.In the crust, the content of silicon in all elements content is second only to oxygen, second.Its shape is divided into crystalline form and network form

- Q: I am a student of refractory materials. I would like to know the general rank of national refractory materials company

- GL-60, high temperature daub, rock wool pipe shell, high quality magnesia brick, high alumina castable explosion-proof, high strength steel fiber steel fiber reinforced corundum castable, refractory castable, alkali brick, sillimanite brick, high alumina brick insulation level, wear-resistant castable, refractory castables for large power plant, silicon mullite brick, alkali resistant castable, blast furnace iron trough castable, super high alumina brick, magnesia spinel brick, castable, magnesia chrome brick, high alumina low cement castable, rock wool board, aluminum corundum brick, magnesia brick etc..

- Q: What kind of refractory material will be used in the glass kiln?

- 1. compact chromium oxide brickIt has the best resistance to high temperature E glass corrosion, its erosion basically does not cause pollution to the glass liquid, so it has become the first choice of E glass unit refractory bricks.Dense chromium oxide is formed by isostatic pressing. Its density is very high. The main technical indexes include Cr2O3 content >94%, porosity <15%, volume density >4.24g/cm3, and erosion loss only 1/10 of compact zirconia brick. Used in the E glass furnace unit kiln, directly contact high temperature molten glass melt, wall, melting parts, high temperature parts, pool bottom, main channel, pool wall and pool bottom, transition channel, pool wall, etc..

- Q: Is it good for your cupola to use that kind of refractory, high aluminum brick, clay brick or red silica?

- The high aluminum clay brick is slightly more stable and can be used!

- Q: Sillimanite brick

- After calcination at high temperature, sillimanite transforms to mullite and free silica. Generally use the firing process and production of high temperature mud casting method. Its physical and chemical properties are better than those of aluminum bricks, the refractoriness is 1770~1830 degrees, and the load softening point is 1500~1650 degrees centigrade. The utility model is mainly used for the forming of a liquid hole in a glass furnace, a lining of a blast furnace, a furnace throat and a ceramic industrial kiln tool.

- Q: What refractory materials are adopted in each part of the blast furnace?

- The blast furnace throat from top to bottom, stack, belly and Bosh, hearth and bottom etc.

Send your message to us

Sillimanite Brick - High Quality Sillimanite Bricks

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords