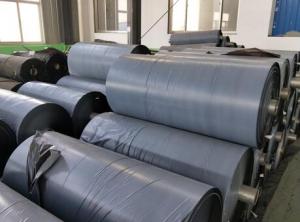

Silicone coated PET release film red,blue,black colors

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 10000000 square meter m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PET release film specifications:

| Specifications | |

| Name | Silicone coated PET release film red,blue,black colors |

| Material | Polyethylene Terephthalate (PET) 100% virgin material |

| Thickness | 23um~250um |

| Coating | One or two sides coating/solvent free or solvent |

| length : | makes as orders |

| Colors : | Transparent, white, blue, yellow or as customer’s requirement |

| Testing equipment | testing equipment from USA |

| Sample | |

| Base coating | Silicone oil |

| Application | Adhesive tape/Label and stickers/MLCC purpose/ electrical industrial products |

| Release force | Light mold and heavy mold |

| Feature: | Good-smoothness and evenly plain |

| Usage: | For surface protection during moving, storage, installation etc |

| MOQ: | 10000 square meter |

| Package: | Carton packing with pallets or as customer’s requirement |

| Business type: | with 16 years manufacture experience |

| Our big client : Haier(China's largest home appliance manufacture) ,LG and so on | |

Our silicone release film is used in applications such as:

Release liner for pressure sensitive labels

Release liner for shingle release

Release liner for cast polymer materials

Process liner for adhesive tape manufacturing

Release film in electronic applications

Process liner where a separation is needed during processing or storage

Release liner in the production of ceramic capacitors

Release liner for the window film market

Technical data:

Item | Unit | Measurement method |

| |||||||

SD02 | SD04 | SD06 | SD08 | SD10 | SD12 | |||||

thickness | um | ASTMD374 | 36~250 | 23~250 | 23~250 | 23~250 | 23~250 | 23~250 |

|

|

Haze | % | ASTMD1003 | 2~10 | 2~10 | 2~6 | 8~10 | 2~10 | 2~10 |

|

|

Peel strength | g/inch | TESA 7475 tape(300mm/180 ) | 12~120 | 4~66 | 5~40 | 4~66 | 8~20 | 5~40 |

|

|

Residual adhesiveness rate | % | NITTO 31B tape | >=85 | 85~97 | 97 | 85~97 | >=95 | 97 |

|

|

Surface wetting tension | Dynes |

|

| 19~40 |

|

|

|

| ||

Quality assurance :

Quality has been our major forte. we are committed to meet and exceed our customers’ expectations by providing top-of-the-line products and prompt services. In our endeavors to achieve optimal customer satisfaction, we have developed a total quality management system under the supervision of quality personnel .Our high quality products have earned us a position of repute in the industry.

- Q: What kind of keyboard protection film is good for you?

- People feel good because of strong adsorption or silica gel, not easy to move.

- Q: Should the protective film of the sole of high-heeled shoes be torn off?

- I suggest that if you don't take it, you'll break it if you don't walk a few steps. Half of it is stuck on half of the shoe and it's floating in the air. Not only is it ugly, but it falls,

- Q: Usually what equipments does it need in processing PE film?

- Using cutting machine is OK! !

- Q: How to easily remove the protective film of the new refrigerator?

- 1, from the refrigerator side of the next blow with the hair dryer for a while, gently to the side all the way up, slowly torn, with a small rod, roll up and pull out can be, so that the force evenly, once all pull open2, with a washed clean foam produced by the warm water, take a cloth to wipe the protective film, and then let it stand for a while, then the film off, it is very easy

- Q: After the camera is attached, some bubbles want to be replaced with another one. How can you pull it out? It's urgent. Can you stick it in a little water? Oh, that's tough

- The film itself has a vent, in between the film and the camera screen space from the clean, the film will cling to the screen, to separate words, must make between the two is filled into the space, can use the nail pick a corner, then slowly is too high, this space will be along the slot into the space, you can tear down.

- Q: Why does PE film curl when rolling it after coating?

- It may happen if the temperature of equipment is too or glue of high adhesion is applied to fairly thin flim. (The solution is to increase the speed or decrease the temperature.) The adhesion of glue is too high because it's too thick, or the base material is not good, or the stress is too strong when drying the film.(Solution: using the inlet air to press the film from the right side to make it flat and ensure the glue won't fall off.) And if the film you use is composite membrane, when the composite membrane is not composited compeletly, the same problem may occur too. I don't know your coating process, thus all above are the possible reasons that I suppose.

- Q: What are the requirements for PE protective films?

- Storage period: storage in warehouse for more than one year, no change in quality;No pollution and no corrosion: the adhesive is inert and will not react with the surface of the glued material;

- Q: What are the main functions of PET protective films?

- 3. glue function is stable, high temperature resistant, can be used for a long time in high temperature environment;4., non residue glue, good acid and alkali resistance;

- Q: What about the keyboard and the protective film on the laptop? Why?

- No, not at all! If you're afraid of dirt or dirt, buy a cleaning kit to help clean up. Of course, it's very dangerous whether you add water or not!First, if you add a bad, such as very soft, silicone do, easy to touch gray, affecting the notebook cooling, and then you typing, it is very uncomfortable.

- Q: What's the difference between the original film and the protective film?

- Fourth: to prevent electromagnetic radiation (film has a certain anti electromagnetic breaking effect), pregnant women and babies born as little as possible contact with radiation of electronic productsFifth: mirror the function of girls favorite (mirror film can be used as a mirror, to attend any place, you can use the phone as a mirror make-up)Sixth: variety of color film to highlight personalitySeventh: diamond film dazzlingEighth: the screen through regular film protection, not only mobile phone screen from scratch, oil contamination, and can reduce the use of mobile phone owners eye fatigue. There are more and more people who like to put their cell phones in their pockets, and most people have the problem that they have mobile phones, keyboards and screens which are easy to get into the dust

Send your message to us

Silicone coated PET release film red,blue,black colors

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 10000000 square meter m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches