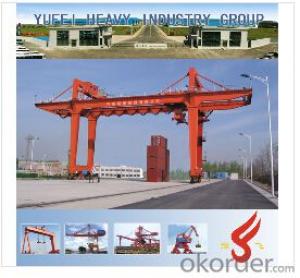

Ship Building Gantry Crane

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Ship building gantry crane is a kind of great lifting capacity, large span, high lifting altitude, multi-function, high efficiency of gantry crane, is special for the fragmented transport, end-to-end joint and turning operation of large ship hulls. Ship building gantry crane is used in the place of manufacturing of ship and dock.

In the past ten years, with the development of large-scale ship building, Shipyard gantry crane for sale, ship building gantry crane is the rapid growth of demand. Compared with the traditional portal crane, large ship building gantry crane has the obvious advantage of the installation and transportation of hull sections. It spans the dock (berth), can provide on-site assembly service at the coverage plane in the dock, not only has the lifting, horizontal transport function, but also can implement hull air turnover, adjusting the fragment to the welding position of ship required.

Features:

1. It have multiple functions of single hanging, hoisting, turnover in the air, slight horizontal turnover in the air and so on;

2. The gantry falls into two categories: single girder and double girder. To rationally utilize materials, the girder adopts optimum design of variable section;

3. The gantry rigid legs with a single column and double column type for customer choice.

4. The upper trolley has two main hooks, which are separately fixed at both sides of the main beam, but the lateral movement can be individually or simultaneously 0 - 2m.

5. The lower trolley has a main hook and auxiliary hook, which fixed below at the center of the two girders;

6. Both the upper trolley and the lower trolley can cross each other for operation;

7. All the lifting mechanism and travelling mechanism adopts frequency conversion speed regulating;

8, On the top of the girder at the side of rigid leg is equipped a jib crane to accomplish maintenance of upper and lower trolley;

9. In order to prevent the storm attack, such safe and reliable anti-wind devices as rail clamp and ground anchor are equipped.

Technical Data:

250t×60m | 300t×108m | 600t×60m | |||||

Duty | A5 | ||||||

Lifting weight | Normal lift | t | 250 | 200 | 600 | ||

Rotate lift | t | 200 | 200 | 400 | |||

Span | m | 60 | 108 | 60 | |||

Lifting height | m | 48 | 70 | Above rail 40 Below rail 5 | |||

Top trolley | Lift weight | t | 100×2 | 100×2 | 200×2 | ||

Lifting Speed | m/min | 0.5-5-10 | 0.5-5-10 | 0.4-4-8 | |||

Running speed | 1~28.5 | 3~30 | 1~25 | ||||

Bottom trolley | Lifting weight | Main hook | t | 100 | 150 | 300 | |

Aux hook | 20 | 20 | 32 | ||||

Lifting speed | Main hook | m/min | 0.5-5-10 | 0.5-5-10 | 0.4-4-8 | ||

Aux hook | 10 | 10 | 10 | ||||

Running speed | 1~26.5 | 3~30 | 1~25 | ||||

Jib crane for maintenance | Lifting weight | t | 5 | 5 | 5 | ||

Lifting speed | m/min | 8 | 8 | 8 | |||

Running speed | 20 | 20 | 20 | ||||

Rotate speed | r/min | 0.9 | 0.9 | 0.9 | |||

Crane travelling speed | m/min | 1~26.5 | 3~30 | 1~25 | |||

Max. wheel presure | kN | 200 | 450 | 430 | |||

Power supply | 380V / 10kV; 50Hz; 3 Phase | ||||||

- Q: This question asks for the proper usage guidelines for a building hoist, a mechanical device used in construction to lift materials.

- <p>To use a building hoist correctly, follow these steps: Ensure the hoist is inspected and certified for safe operation. Check all safety devices, including limit switches and emergency stops, are functioning. Securely attach the load to the hoist's hook, ensuring it's balanced and within weight limits. Never exceed the hoist's capacity. Operate the hoist with caution, avoiding sudden starts or stops. Keep the hoist area clear of people and obstacles. Use a tag line to guide the load if necessary. Always lower the hoist when not in use and secure it against wind or other forces. Regular maintenance and inspections are crucial to prevent accidents.</p>

- Q: What measures should be taken to ensure safety when operating electric-motor powered building hoists?

- <p>When using electric-motor type building hoists, safety precautions include: ensuring all safety devices are in good working order, regularly inspecting and maintaining the hoist, following the manufacturer's guidelines, never overloading the hoist, keeping the hoist and its surroundings clean and free from obstructions, using proper lifting techniques, ensuring the hoist is stable and secure, wearing appropriate personal protective equipment, and training operators on the safe use of the hoist. Adhering to these precautions can significantly reduce the risk of accidents and ensure the safety of workers and the integrity of the construction process.</p>

- Q: The user is asking if it's possible for them to fix their own building hoist without professional assistance.

- <p>While it is technically possible to repair your own building hoist, it's generally not recommended unless you have specific expertise in hoist maintenance and repair. Building hoists are complex mechanical systems that require knowledge of safety regulations and proper repair techniques. Attempting repairs without proper training can lead to accidents or further damage. It's best to hire a professional who is familiar with the specific model and has the necessary certifications to ensure the hoist is safe and functioning correctly.</p>

- Q: This question asks about the typical issues that can arise with building hoists, which are mechanical devices used in construction to lift materials and workers.

- <p>Common problems with building hoists include mechanical failures such as broken cables or chains, malfunctioning brakes, and worn-out gears. Electrical issues like short circuits or damaged control panels can also occur. Safety hazards may arise from improper installation or maintenance, leading to accidents. Overloading the hoist can cause structural damage and failure. Environmental factors like extreme weather conditions can affect performance and longevity. Regular inspections and maintenance are crucial to prevent these problems and ensure the safe operation of building hoists.</p>

- Q: Is it possible for a building hoist to lift more than one object simultaneously?

- <p>Yes, a building hoist can lift multiple objects at once, provided the combined weight does not exceed the hoist's maximum load capacity. The hoist's design and specifications will dictate how many and what types of objects can be lifted simultaneously. It's crucial to follow the manufacturer's guidelines to ensure safety and prevent damage to the hoist or the objects being lifted.</p>

- Q: This question asks for a list of various types of cables that are utilized in lifting equipment.

- <p>Lifting equipment employs several types of cables, each designed for specific purposes. The primary types include: 1. Wire ropes, which are the most common and are used for their strength and flexibility. 2. Chain slings, which are strong and durable but less flexible than wire ropes. 3. Synthetic slings, made from materials like nylon or polyester, offering lighter weight and resistance to chemicals. 4. Round slings, providing a smooth surface to protect loads from damage. 5. Wire rope slings, which are versatile and can be used in various configurations. 6. Aircraft cables, known for their high strength and resistance to corrosion. 7. Endless wire rope slings, which are used for heavy loads and offer a looped design. Each type of cable has its own set of advantages and is chosen based on the specific requirements of the lifting task.</p>

- Q: Can a building hoist experience failure due to mechanical problems or the natural aging process?

- <p>Yes, a building hoist can malfunction due to mechanical issues or wear and tear. Mechanical problems can arise from various factors such as poor maintenance, overloading, or manufacturing defects. Wear and tear, which is the gradual deterioration of a machine's parts over time, can also lead to malfunctions. Regular inspections and maintenance are crucial to identify and rectify these issues, ensuring the safety and efficiency of the hoist operation.</p>

- Q: Is it possible to utilize a building hoist to lift objects with varying dimensions and weights?

- <p>Yes, building hoists are designed to lift a variety of objects with different sizes and weights. However, each hoist has specific weight and size limitations that must be adhered to for safety and operational reasons. It's crucial to ensure that the objects being lifted are within the hoist's capacity to prevent accidents and damage. Always consult the manufacturer's specifications and safety guidelines before using a hoist for lifting operations.</p>

- Q: This question asks if improper functioning or lack of maintenance in hydraulic cylinders can lead to damage.

- <p>Yes, hydraulic cylinders can cause significant damage if they malfunction or are not properly maintained. Malfunctions can lead to leaks, component failure, or even structural damage due to pressure surges. Lack of maintenance can cause wear and tear, leading to reduced efficiency and potential failure. Regular maintenance, including checking for leaks, ensuring proper lubrication, and replacing worn parts, is crucial to prevent damage and ensure the safe operation of hydraulic systems.</p>

- Q: Is it possible to replace an electric motor with a hydraulic cylinder in an electric-hydraulic lifting system?

- <p>No, a hydraulic cylinder cannot be used in place of a motor in an electric-hydraulic lifting system. A hydraulic cylinder is a component that converts hydraulic pressure into linear motion, while an electric motor converts electrical energy into mechanical energy. In an electric-hydraulic system, the motor drives a hydraulic pump, which generates the pressure needed to actuate the cylinder. The motor is essential for providing the power source, and the cylinder is the actuator that uses this power to perform work. Replacing the motor with a cylinder would result in a system without a power source, rendering it inoperative.</p>

Send your message to us

Ship Building Gantry Crane

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords