SC200ZA Frequency Conversion Hoist

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 60 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Construction Hoist Description

Single cage

Rated Capacity: 2 Ton

Lifting speed: 0~33min/0-45m/min/0-90m/min

Motor power: 2x3x11kw

Inverter power: 45kW

Cage size (Length x width x height): 3x1.4x2.25m

Mast size (Length x width x height): 650x650x1508mm

Safety device: anti-dropping tripper

Mast weight: 124.2 kg(with one rack)

Loading information: 1*40 HQ can load 60m high SC200ZBconstruction hoist

Features of Construction Hoist

● The gearing adopts imported bearing, enameled cable, and oil seal.

● The electric parts adopt products from world renowned manufactures such as Schneider, Siemens, and LG.

● The racks and pinion adopts special material and heat-treatment technique, which prolong the life of these parts.

● The steel structure uses quality steel from famous domestic manufactures.

● The surface of the structure can apply paint-spray, or hot galvanizing processing according to users requirements,

● The cage can be produced and decorated by aluminum molded board, punched-plate or figured aluminum board.

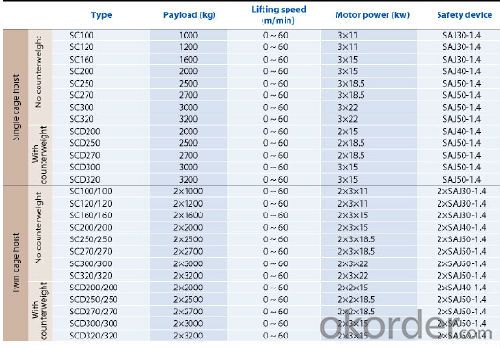

Construction Hoist Specifiction

FAQ of Construction Hoist

Q: What is the building hoist main purpose?

A: Building hoist equipped with double or single cabin to transport the materials and labors up and down. It's the ideal

construction equipment for vertical transportation in the field of construction.

Q: What is the main structure of building hoist?

A: The P/M construction hoist mainly contains metal structure, driving system, electrical control system, cable guide &

protection system, electrical top crane and safety device.

Q: What is the meaning of the building hoist’s code?

A: Take SC200/200 for example: “SC” stands for rack and pinion hoist, “200/200” stands for double cage and capacity

is 2 tons per cage. “SC200” stands for single cage and capacity is 2 tons.

- Q: Construction elevator positioning should consider which problems

- It is convenient to install the wall with the wall

- Q: Can construction elevators be taken by people or by goods

- ?yes, you can! It is to pass the authority authority to issue use card to be able to use! Construction lifts are also called elevators

- Q: How many kw is the sc construction elevator

- The construction elevator sc200/200 is rated at 63 kw power, and the power consumption is greater.

- Q: Is it possible to utilize a building hoist for the purpose of moving materials up and down in a warehouse setting?

- <p>Yes, a building hoist can be used to lift and lower materials in warehouses. These hoists are designed for vertical transportation of goods and are particularly useful in multi-story warehouses where space is limited. They are capable of handling heavy loads and can be operated manually or with electric power, making them efficient for moving materials between different levels of a warehouse. However, safety measures and proper maintenance are crucial to ensure the secure and effective operation of the hoist.</p>

- Q: How many floors are built to use the construction elevator? With six floors?

- The country stipulates above 7 floor to be installed elevator, of course 7 below can be installed not outfit, average 7 floor below is a ladder of ladder of ladder of ladder of ladder of ladder of ladder of ladder of ladder of stairs and so on

- Q: This question asks whether a building hoist can be utilized in construction or demolition activities.

- <p>Yes, a building hoist can be used for both construction and demolition work. In construction, hoists are essential for transporting materials and personnel vertically within a building under construction. They are designed to handle heavy loads and operate safely at significant heights. In demolition, hoists can be used to remove debris and transport workers to different levels of a structure being dismantled. However, it's crucial to ensure that the hoist is suitable for the specific task and that all safety protocols are followed to prevent accidents.</p>

- Q: This question asks about frequent issues related to building hoists and seeks solutions for these problems.

- <p>Common problems with building hoists include mechanical failures, electrical issues, overloading, and safety malfunctions. Mechanical failures can be fixed by regular maintenance, lubrication, and replacement of worn parts. Electrical problems may require checking wiring, connections, and replacing faulty components. Overloading can be prevented by strictly adhering to the hoist's weight limit and using load indicators. Safety malfunctions, such as brake failure, require immediate attention and may involve replacing brake pads or overhauling the braking system. Always ensure that hoists are used according to the manufacturer's guidelines and are regularly inspected by qualified personnel to prevent accidents and ensure safe operation.</p>

- Q: What are the necessary maintenance and inspection procedures for hydraulic building hoists to ensure their safe and efficient operation?

- <p>Hydraulic building hoists require regular maintenance and inspection to ensure safety and efficiency. Daily checks should include visual inspections for leaks, proper functioning of controls, and safe operation of the hoist. Monthly inspections should cover the condition of hydraulic hoses, cylinders, and seals. Annual inspections should be conducted by a qualified professional to check the structural integrity, load-bearing components, and overall mechanical condition of the hoist. Regular lubrication of moving parts and replacement of worn components are also crucial. Always adhere to the manufacturer's guidelines and local regulations for maintenance and inspection intervals.</p>

- Q: Is it possible to utilize alternative lifting equipment in place of a building hoist for specific tasks?

- <p>Yes, for certain tasks, alternative lifting equipment can be used instead of a building hoist. Cranes, forklifts, and telescopic handlers are common substitutes. The choice depends on the task's specific requirements, such as the weight of the load, the height to which it needs to be lifted, and the available space. Each piece of equipment has its own advantages and limitations, so it's crucial to select the appropriate one based on the project's needs to ensure safety and efficiency.</p>

- Q: How many meters is the wall of the construction elevator?

- It seems that there is no, just the local code, you search for the construction elevator acceptance specification look, I have searched this aspect before, now forget.

Send your message to us

SC200ZA Frequency Conversion Hoist

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 60 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords