SC200D Frequency Conversion Hoist

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 60 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Construction Hoist Description

Single cage

Rated Capacity: 2 ton

Lifting speed: 0~33min/0-45m/min/0-90m/min

Motor power: 2x3x11kw

Inverter power: 45kW

Cage size (Length x width x height): 3x1.4x2.25m

Mast size (Length x width x height): 650x650x1508mm

Safety device: anti-dropping tripper

Mast weight: 124.2 kg(with one rack)

Loading information: 1*40 HQ can load 60m high SC200ZBconstruction hoist

Features of Construction Hoist

It is vertical transport machinery driving with pinion and rack, applies to engineering of high rise, and is efficient construction machinery for vertical transport of building materials and personnel. As a permanent or sub-permanent external elevator, it also applies to storehouse, high tower, etc.

There are single cage and double cages hoist. According to the needed get rid of one cage of double cages the hoist will be changed to single cage hoist.

SC hoist is equipped with reliable electrical and mechanical safety device. It is a efficient and safety vertical transporting equipment.

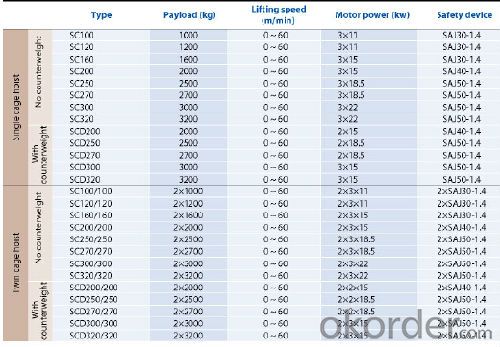

Construction Hoist Specifiction

FAQ of Construction Hoist

Q: What is the main structure of building hoist?

A: The P/M construction hoist mainly contains metal structure, driving system, electrical control system, cable guide &

protection system, electrical top crane and safety device.

Q: What is the meaning of the building hoist’s code?

A: Take SC200/200 for example: “SC” stands for rack and pinion hoist, “200/200” stands for double cage and capacity

is 2 tons per cage. “SC200” stands for single cage and capacity is 2 tons.

Q: What is the dimension of the cage?

A: Normally the cage dimension is 3X1.5X2.5M (L/W/H) for 2t type hoist. Details should be checked according to our

quotation sheet. Also, the size can be customized according to the factual site condition. There are two doors (entrance

& exit doors) for each cage, It can be produced as up & down sliding or ramping model for safety and convenience.

- Q: This question asks for the proper usage guidelines for a building hoist, a mechanical device used in construction to lift materials.

- <p>To use a building hoist correctly, follow these steps: Ensure the hoist is inspected and certified for safe operation. Check all safety devices, including limit switches and emergency stops, are functioning. Securely attach the load to the hoist's hook, ensuring it's balanced and within weight limits. Never exceed the hoist's capacity. Operate the hoist with caution, avoiding sudden starts or stops. Keep the hoist area clear of people and obstacles. Use a tag line to guide the load if necessary. Always lower the hoist when not in use and secure it against wind or other forces. Regular maintenance and inspections are crucial to prevent accidents.</p>

- Q: This question asks for a comparison of the pros and cons associated with the use of electric building hoists in construction.

- <p>Electric building hoists offer several advantages such as ease of operation, reduced manual labor, and increased efficiency in lifting and transporting materials. They are also safer compared to manual hoists, reducing the risk of accidents. Additionally, they can handle heavier loads and operate in various weather conditions. However, they have some disadvantages too. For instance, they require a power source and can be less reliable during power outages. They also involve higher initial costs and maintenance expenses. Electric hoists can be noisy, which may lead to noise pollution, and they can be complex to install and operate, requiring skilled personnel.</p>

- Q: This question asks whether building hoists can be used in both indoor and outdoor environments.

- <p>Building hoists can be used both indoors and outdoors, but their usage depends on the specific type and design of the hoist. Material hoists, for instance, are often used outdoors in construction sites to lift materials vertically. On the other hand, dumbwaiters are hoists designed for indoor use, typically to transport goods between floors in buildings. It's important to ensure that the hoist is suitable for the environment in which it will be used, considering factors such as weather conditions, building structure, and safety regulations.</p>

- Q: This question asks if a building hoist is capable of lifting objects that vary in size and weight.

- <p>Yes, a building hoist can be used to lift objects of different sizes and weights, but it is crucial to ensure that the hoist's capacity is suitable for the load. Building hoists are designed to handle various materials and equipment during construction, and their lifting capacity can range from a few hundred pounds to several tons. It is essential to check the hoist's specifications and adhere to the maximum load limit to ensure safety and prevent damage to the hoist or the objects being lifted. Always follow the manufacturer's guidelines and safety standards when operating a building hoist.</p>

- Q: This question asks whether a building hoist can be utilized in both indoor and outdoor environments.

- <p>A building hoist can indeed be used both indoors and outdoors, depending on the specific model and design. Outdoor hoists are typically built to withstand weather conditions and are more robust, while indoor hoists are designed for controlled environments. It's crucial to ensure that the hoist is suitable for the intended environment to maintain safety and functionality. Always follow the manufacturer's guidelines and safety regulations when using a building hoist in any setting.</p>

- Q: This question asks whether a building hoist can be utilized in construction or demolition activities.

- <p>Yes, a building hoist can be used for both construction and demolition work. In construction, hoists are essential for transporting materials and personnel vertically within a building under construction. They are designed to handle heavy loads and operate safely at significant heights. In demolition, hoists can be used to remove debris and transport workers to different levels of a structure being dismantled. However, it's crucial to ensure that the hoist is suitable for the specific task and that all safety protocols are followed to prevent accidents.</p>

- Q: Is it permissible to utilize electric or hydraulic building hoists in personal workshops or factories?

- <p>Yes, you can use an electric or hydraulic building hoist in your own workshop or factory. However, you must ensure that the hoist complies with local safety regulations and standards. It's crucial to have the hoist installed by qualified professionals and to maintain it regularly to prevent accidents. Always follow the manufacturer's guidelines and safety protocols to ensure the safe operation of the hoist.</p>

- Q: Is it possible to utilize a building hoist for the transportation of heavy objects?

- <p>Yes, building hoists are specifically designed to move heavy objects vertically within a construction site. They are used to lift and lower materials such as concrete, bricks, and other construction supplies. Building hoists are equipped with strong cables and a robust mechanism to handle significant weight, making them ideal for heavy-duty lifting tasks in construction projects. However, it's crucial to ensure that the hoist is operated within its weight capacity and safety guidelines are strictly followed to prevent accidents.</p>

- Q: Is it possible to utilize a hydraulic cylinder in the construction of a building hoist?

- <p>Yes, hydraulic cylinders can be used in building hoists. They are often employed in lifting systems due to their ability to generate large forces in a controlled manner. Hydraulic cylinders provide smooth and precise control over heavy loads, which is crucial for the safe and efficient operation of a building hoist. They can handle the vertical movement of materials and personnel in construction settings, ensuring a stable and reliable lifting mechanism.</p>

- Q: This question asks whether a building hoist can be used in both indoor and outdoor construction settings.

- <p>Yes, a building hoist can be used both indoors and outdoors for construction work. These hoists are versatile and designed to facilitate the movement of materials and personnel in multi-story buildings. Outdoors, they are often used during the construction of high-rise buildings, while indoors, they can be used for the vertical transportation of materials in large structures like shopping malls or office buildings. It's important to ensure that the hoist is suitable for the specific conditions, such as weather resistance for outdoor use, and that safety protocols are strictly followed to prevent accidents.</p>

Send your message to us

SC200D Frequency Conversion Hoist

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 60 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords