SC200 Building Hoist (Passenger Hoist) for Sale

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Building Hoist:

1). Cage load capacity: 1000kgs-3200kgs

2). Lifting speed: 36m/min, 0 - 63m/min, 0 - 96m/min

3). Mast section: Painted or hot dipped zinc

4). Cage: Single cage or twin cage

5). Recommended cage inner dimensions (L x W x H): 2.5 x1.3 x 2.5m, 3.0 x 1.3 x 2.5m, 3.2 x 1.5 x 2.5m, 3.6 x 1.5 x 2.5m, 3.8 x 1.5 x 2.5m, 4.0 x 1.5 x 2.5m, 4.2 x 1.5 x 2.5m, according to requirements of customers

6). Motor and reducing device: Made in China, or uses SEW according to requirements

7). Counterweight: With counterweight or without counterweight

8). Color of cage: Yellow, red, blue or your request

9). Cage load capacity: 1, 000kg, 1, 200kg, 2, 000kg, 2, 700kg or 3, 200kg

10) including VFD or without VFD.

Ketong Building hoist superiority:

1. Smoothly starting and stopping without surging or jarring the elevator car.

2. The lifing speed can be easily controlled and is infinitely variable

3. The elevator starting current is lower than rated current.

4. By using the frequency conversion device greatly reduces mechanical wear and tear oil the elevator and its components

5. The frequency conversion drive is more emcient and uses less power.

Advantages of Building hoist

Our advantage:

1- More than 130,000 employee.

2- state-owned company and Fortune 500 enterprises.

3- own systems of production engineering.

4- 10 service branch in the work, such as UAE. KSA. IRAN, USA. INDIA, RUSSIA...

5- Professional construction equipment supplier.

6- technical experts with great experience in the sector.

7- More pls visit our factory, you will find we are your best choice.

Hoist Advantages:

1. Quality raw material, strict production management and career responsibility to make the hoist with the highest safety control, and the advanced design make it with good vision to enhance the safety.

2. Simple structure and low cost

3. Convenient in installation, disassembly and maintenance.

4. Energy-saving, starting current is lower than the rated current.

5. Adjustable speed, the maximum speed could reach 96m/min.

6. Frequency conversion control system, stable starting and breaking and low mechanical wear .

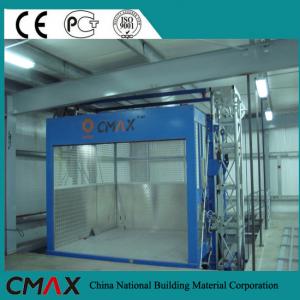

Building Hoist Images:

Building hoist Specifiction:

Elevator classification | Cage | Model | Rated load capacity(kg) | Lifting speed(m/min) | Moter power(kw) | Dimension inside cage (L*W*H)(m) |

Normal construction elevator | single cage | SCD200 | 2000 | 33 | 2*11 | 3.0*1.3*2.4 (3.2*1.5*2.4) |

SC200 | 2000 | 33 | 3*11 | |||

double cage | SCD200/200 | 2*2000 | 33 | (2*2) *11 | ||

SC200/200 | 2*2000 | 33 | (2*3)*11 | |||

SS100/100 | 2*1000 | 24 | 2*7.5 | |||

Frequency construction elevator | Single cage | SCD200 | 2000 | 0-63 | 3*15 | |

SC200 | 2000 | 0-63 | 3*15 | |||

Double cage | SCD200/200 | 2*2000 | 0-63 | (2*3)*15 | ||

SC200/200 | 2*2000 | 0-63 | (2*3)315 |

FAQ of Building Hoist:

Q: What is the building hoist main purpose?

A: Building hoist equipped with double or single cabin to transport the materials and labors up and down. It's the ideal

construction equipment for vertical transportation in the field of construction.

Q: What is the main structure of building hoist?

A: The P/M construction hoist mainly contains metal structure, driving system, electrical control system, cable guide &

protection system, electrical top crane and safety device.

Q: What is the meaning of the building hoist’s code?

A: Take SC200/200 for example: “SC” stands for rack and pinion hoist, “200/200” stands for double cage and capacity

is 2 tons per cage. “SC200” stands for single cage and capacity is 2 tons.

Q: What is the dimension of the cage?

A: Normally the cage dimension is 3X1.5X2.5M (L/W/H) for 2t type hoist. Details should be checked according to our

quotation sheet. Also, the size can be customized according to the factual site condition. There are two doors (entrance

& exit doors) for each cage, It can be produced as up & down sliding or ramping model for safety and convenience

- Q: What measures should be taken to ensure safety when operating electric-motor powered building hoists?

- <p>When using electric-motor type building hoists, safety precautions include: ensuring all safety devices are in good working order, regularly inspecting and maintaining the hoist, following the manufacturer's guidelines, never overloading the hoist, keeping the hoist and its surroundings clean and free from obstructions, using proper lifting techniques, ensuring the hoist is stable and secure, wearing appropriate personal protective equipment, and training operators on the safe use of the hoist. Adhering to these precautions can significantly reduce the risk of accidents and ensure the safety of workers and the integrity of the construction process.</p>

- Q: What are the alternative uses of a building hoist besides construction?

- <p>Yes, building hoists can be used for other purposes beyond construction. They can be utilized in various industries for material handling, such as in warehouses for moving goods, in factories for lifting machinery, and in maintenance for accessing high areas. Additionally, building hoists can be employed in emergency services for rescue operations, especially in high-rise buildings. They are also used in special events for setting up stages and equipment. The versatility of building hoists makes them a valuable tool in many different scenarios where vertical transportation of materials or personnel is required.</p>

- Q: This question asks for criteria or factors to consider when selecting the appropriate type of building hoist for a specific construction project.

- <p>Choosing a suitable type of building hoist involves considering several factors: the weight and size of materials to be lifted, the frequency of hoisting, the height of the building, and safety requirements. Assess the load capacity needed, as hoists vary in their lifting capabilities. Consider the hoist's speed and efficiency to ensure it meets the project's timeline. The hoist's size and maneuverability are crucial for fitting within the construction space. Safety features and certifications should be verified to ensure compliance with industry standards. Consulting with hoist manufacturers or rental companies can provide insights into the most suitable hoist for your specific application.</p>

- Q: Can a building hoist experience failure due to mechanical problems or the natural aging process?

- <p>Yes, a building hoist can malfunction due to mechanical issues or wear and tear. Mechanical problems can arise from various factors such as poor maintenance, overloading, or manufacturing defects. Wear and tear, which is the gradual deterioration of a machine's parts over time, can also lead to malfunctions. Regular inspections and maintenance are crucial to identify and rectify these issues, ensuring the safety and efficiency of the hoist operation.</p>

- Q: What are the necessary maintenance tasks and considerations for ensuring the safe and efficient operation of a building hoist?

- <p>The maintenance requirements for a building hoist include regular inspections, lubrication, and checks on all mechanical components. It is crucial to inspect the hoist's cables, pulleys, and brackets for wear and tear. The drive mechanism and safety devices should be tested for proper functioning. Lubrication of moving parts is essential to reduce friction and prevent overheating. Additionally, the electrical system should be checked for any faults or damage. It's important to keep the hoist clean and free of debris to prevent any operational issues. Following the manufacturer's guidelines for maintenance intervals and procedures is vital to ensure the hoist remains safe and efficient.</p>

- Q: This question asks for the steps or methods to keep a building hoist in good condition and fix any damages.

- <p>To maintain and repair a damaged building hoist, follow these steps: Regularly inspect the hoist for wear and tear, checking cables, pulleys, and brackets. Lubricate moving parts to reduce friction and prevent rust. Replace damaged or worn-out components promptly. Ensure all safety features are functioning correctly. If a hoist is severely damaged, consult with a professional to assess the damage and perform necessary repairs. Always adhere to the manufacturer's guidelines and safety regulations during maintenance and repair processes.</p>

- Q: What is the need for the sc200/200 construction elevator cable?

- The sc200/200 construction elevator cable line should not be below 120 square. Man's ladder 33KW, 5 * 33 = 165KW The tower is 45KW one, 2 * 45 = 90KW The pressure slag welder is estimated to be 25KW Touch welder 1OKW, 5 * 10 = 50KW Other facilities such as mixer, temporary illumination etc. 30KW Total power: 165 + 90 + 25 + 50 + 30 = 365KW One square cable is 5 minus 7A, 380V is 1KW is equal to 2A. That's 730A 730A divided by 5-7 calculates that the cable line should not be less than 120 square.

- Q: Explain the key differences between electric and pneumatic lifting equipment in a few sentences.

- <p>Electric lifting equipment is powered by electricity and offers precise control, high efficiency, and is suitable for heavy-duty applications. Pneumatic lifting equipment, on the other hand, is powered by compressed air and is known for its simplicity, safety, and lower cost. It is often used in environments where electrical equipment might be hazardous, such as in the presence of flammable gases or dust. Electric systems can handle heavier loads and provide more precise control, while pneumatic systems are more resistant to overload and offer a fail-safe mechanism in case of air pressure loss.</p>

- Q: This question asks for guidelines on how to take care of lifting equipment after it has been used.

- <p>To maintain your lifting equipment after use, follow these steps: 1. Clean the equipment thoroughly to remove dirt, grease, and any debris. 2. Inspect all components for wear, damage, or signs of excessive use. 3. Lubricate moving parts as per the manufacturer's recommendations. 4. Check and tighten all bolts, nuts, and fasteners to ensure they are secure. 5. Store the equipment in a dry, clean, and well-ventilated area to prevent rust and corrosion. 6. Regularly review the manufacturer's maintenance schedule and perform any required servicing. 7. Keep a log of all maintenance and inspections to ensure you're staying on top of equipment care. Proper maintenance not only prolongs the life of your equipment but also ensures safety during use.</p>

- Q: Is it safe to use a lifting device with someone who has no experience with it?

- <p>It is generally not advisable to use a lifting device with someone who is not familiar with it. Lifting devices require proper training and understanding of their operation to ensure safety. Using such equipment without proper knowledge can lead to accidents and injuries. It is crucial to ensure that anyone operating a lifting device has received the necessary training and is familiar with the specific device's safety protocols and operation procedures.</p>

Send your message to us

SC200 Building Hoist (Passenger Hoist) for Sale

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords