Fiberglass Mesh Cloth Sanding Screen Discs Hot Selling Low Price 400C

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Sanding Screen Discs Description:

Sanding Screen Discs is made of nylon fabric, coated with abrasive materials; there are three kinds of shape: Sheets, Discs and Rolls.It is not only suitable for sanding plaster and wall surface, but also for sanding rusty spots of metal materials and making grinding and polishing treatment. It has good properties of grinding, cutting and filings removing. And it is the most ideal abrasive tool for interior decoration.

2.Main Features of Sanding Screen Discs:

High grinding efficiency, fine functioning in chip removal, excellent water tolerance and long service life

Has excellent performances of grinding, cutting and filings removing.

Being coated with abrasive materials on each side, both sides of the screens can be used

Sanding Surface of woodworking, plaster metal, plastic, enamel and remove rusty and making grinding and polishing treatment.

Easily cleaned by water, dried by air for reuse

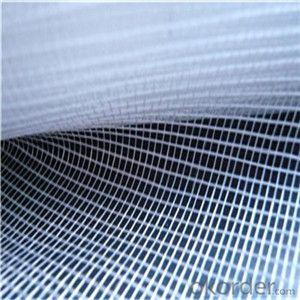

3. Sanding Screen Discs Images

4. Sanding Screen Discs Specification

| Sanding Screen Discs | |

| Backing | Fiberglass mesh |

| Abrasive | Silicon carbide, aluminum oxide |

| Color | Red, green, blue, white, yellow, black ,etc |

| Material | Fibreglass |

| Coating style | Close coated |

| Max width | according to customer requirements |

| Waterproofness | Good, can use wer or dry |

| Finished Shape | Sheet |

| Roll | |

| Disc | |

| Grit Range | P40-P600 |

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: How is fiberglass mesh used?

- The wall should be cleaned before paving and the pits will be patched and leveled

- Q: How do you paste the mesh cloth on the back of the stone?

- This is only for those of the plate (plate - not for the world) and cut out of the finished product, there is no side treatment.

- Q: Where are the steel wire mesh and the alkali resistant grid cloth used in the exterior wall insulation?

- The wall is filled with aerated blocks. Use shotcrete interface agent and then steel wire mesh. Is the foundation for the structure of the wall, after the thermal expansion and contraction, plastering no hollowing, cracking. Using mesh cloth for full paving. To reach the wall roughness, strengthen the surface cohesion, and consolidate the grassroots. Steel nets are generally used in the decoration, in the masonry wall and the original wall of the junction, but also can be used in the light body wall reinforcement. Mesh cloth is suitable for use in many parts.

- Q: What's the use of fiberglass mesh?

- Glass fiber mesh cloth with alkali resistant fiberglass mesh, it uses alkali free glass fiber yarn (the main ingredient is silicate, good chemical stability) by structure leno weaving and special organization, after the anti alkali, heat setting treatment such as reinforcing agent.

- Q: What kind of wall fabric is covered with fiberglass mesh? Do you apply the powder or the powder? Thank you

- And the wallFully paved, just an industry standard, the requirements are yes, but rare, there are really such a use, on the one hand is the cost, on the one hand is now mostly cast-in-place, there is no need!

- Q: Can fiberglass mesh waste be recycled? What can you do if you can?

- Mesh cloth, such as discarded cloth, is not corrosive and may not corrode for hundreds of years, causing serious pollution to the land;

- Q: Glass fiber mesh fabric stereotypes poor, general use of glue is acrylic emulsion, please add what accessories, you can finalize a better shape

- Add a bit of gum, and the mesh will become harder

- Q: What is the difference between alkali resistant fiberglass mesh and glass fiber mesh fabric?

- Therefore, the utility model has the advantages of good alkali resistance, flexibility, and high tensile resistance at warp and weft direction. The utility model can be widely used for heat preservation, water resistance and crack resistance of walls inside and outside buildings. Glass fiber mesh cloth with alkali resistant fiberglass mesh, it uses alkali free glass fiber yarn (the main ingredient is silicate, good chemical stability) by structure leno weaving and special organization, after the anti alkali, heat setting treatment such as reinforcing agent.

- Q: Self making method and formula of glass fiber mesh cloth shaping glue

- The external wall insulation mesh (glass fiber mesh) with alkali or alkali glass fiber yarn, woven glass fiber mesh to the substrate, and then a new alkali resistant products coated with acrylic copolymer solution after drying into. The product has the advantages of stable structure, high strength, good alkali resistance, corrosion resistance, crack resistance, etc., and the enhancement effect is the best, and the construction is simple and easy to do. Mainly used for cement, gypsum, wall, building and other structures to enhance the internal and external surface, crack prevention, is a new type of building materials insulation project.

- Q: What is the use of alkali resistant fiberglass mesh cloth on the exterior wall?

- Standard: to strengthen the material function and alkali fiberglass mesh cloth to external wall thermal insulation layer, the main role is: to improve the mechanical strength of the surface layer, ensure the continuity of the surface layer resistance, shrinkage pressure and insulation dispersed surface layer stress, avoid stress concentration, surface resistance nature temperature and humidity changes and accidents caused by the impact of the cracking. Therefore, alkali resistant glass fiber mesh fabric plays an important role in the external insulation system, so the selection of good glass fiber mesh fabric is also an important component to ensure the comprehensive quality of the external insulation system. The current national standard technology of exterior insulation (JG149-2003): glass fiber warp and weft resistance tensile strength shall not be less than 750N/50mm, alkali resistant tensile strength retention rate of not less than 50%, more than 130 grams of weight per square meter.

Send your message to us

Fiberglass Mesh Cloth Sanding Screen Discs Hot Selling Low Price 400C

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords