SAND MAKING - VSI Vertical shaft Impact crusher

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

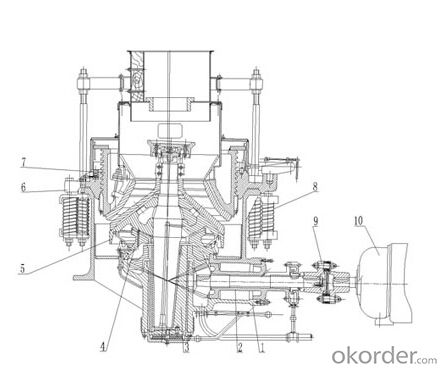

Vertical Shaft Impact crusher (VSI Sand Making Machine) uses a unique rock on rock crushing method employing a high speed rotor with crushing chamber of the equipment. Velocity is applied in Vertical Shaft Impact crushers as the resulting force, to break stone particles. While applying velocity rather than surface force the breaking force to be applied evenly on the surface of the rock.

In Vertical Shaft Impactors material to be crushed hit the other similar covering materials at very high velocity, simultaneously the same crushed particles come in collision with another particles frequently. The feed particles again acquire the velocity with he high impact of the kinetic energy of each other. The particles crack and crush under their mutual hit and force.

Vertical Shaft Impact crusher(VSI Sand Making Machine) gives perfect shape of final product. With the help of VSI crusher fine and course material production becomes easy and convenient . The output size in fine or coarse aggregates can be controlled by adjusting velocity of the input material and the distance between the end of the rotor and the impact point. The final output is cubicle in shape. VSI type of crusher is appropriate for materials with high abrasive property and silica content.

Vertical Shaft Impact crusher(VSI Sand Making Machine) consumes less energy to operate. VSI is equipped with double pump oil lubrication system and work on stone to stone crushing theory so the wear of components is minimum hence lower maintenance results lower operating cost in comparison to other similar stone breakers. It is easy to use due to simple operation mechanism.

1. Advanced double-pump oil lubrication system guarantee shaft bearing lower temperature increase, longer life time, more reliable operation.

2. Main shaft is equipped with imported precision rolling bearing. It makes main shaft work stable, lengthen maintenance cycle, increases productivity.

3. Hydraulic lifting mechanism of upper cover can move away the cover easily, which saves man power during maintenance.

4. Over-vibration device is equipped. There will be alarm when vibration surpasses a stipulated figure. It will stop the machine, in order to protect it.

5. Special dust-proof design for main shaft bearing fully avoid dust entering bearing lubrication part, which make sure the machine work normally.

6. Special feed opening structure makes it possible that center feeding and ring feeding comes together, in order to meet requirement of different stones. In addition, this equipment can not only crush stone, but also iron.

7. Shape of material-through device is better designed, which improve the utilization ratio.

1. Center Feeding:

Raw material falls down into feed hopper, then enters impellor through central entrance hole. It is accelerated in high-speed impellor, then is thrown out at speed of 60-75m/s. When hitting impact plate, it is crushed. Final products come downwards though outlet.

2. Ring Feeding:

Raw material falls down into feed hopper, then through ring, it is devided into two parts by material-dividing plate. One enters into impellor through the center of material-dividing plate. The other falls down from outside of material-dividing plate. Material, which is thrown out by impellor at speed of 60-75m/s, hits material coming down from outside of material-dividing plate. In this way, material is crushed.

| Model | VSI7611 | VSI8518 | VSI9526 | VSI1140 | |

| Capacity (t/h) | Center and Ring feeding | 120-180 | 200-260 | 300-380 | 450-520 |

| Center feeding | 60-90 | 100-130 | 150-190 | 225-260 | |

| Max Feed Size (mm) | Soft material | <35 | <40 | <45 | <50 |

| Hard material | <30 | <35 | <40 | <45 | |

| Rotation speed (r/min) | 1700-1890 | 1520-1690 | 1360-1510 | 1180-1310 | |

| Power for double motor (kW) | 110 | 180 | 264 | 400 | |

| Overall Dimension L×W×H (mm) | 4100×2250×2285 | 4140×2280×2425 | 4560×2450×2780 | 5100×2690×3200 | |

| Weight (t) | 7.8 | 10.3 | 16 | 25.6 | |

| Power Source | 380v 50Hz | ||||

| Vibrating Sensor | Inspect scope: 0.1-20mm/s adjusted continuously | ||||

| Lubrication hydraulic pressure station | Power for double oil pump | 2×0.31kW | |||

| Safety | To make sure the supply of the oil with double oil pump; stop working without oil or hydraulic pressure; temperature falls when the water cools; start the motor by heating it in winter. | ||||

| Overall dimension L×W×H(mm) | 820×520×1270 | ||||

| Power for oil box heater | 2 kW | ||||

- Q: What are the differences between dry sand making and wet sand making?

- Impact sand or centrifugal sand making machine, and semi-dry sanding process used by the sand machine can only use the impact of vertical shaft sand machine, which is the biggest difference between the two.

- Q: The composition of sand making machine

- The new type of sand making machine (vertical shaft impact crusher) for hardness is not higher than 320Pa soft or medium hard and extremely hard ore material broken, sand making machine is widely used in large, smelting, building materials, roads, railways,

- Q: Vertical sand making machine and horizontal sand making machine which is good

- , The general production mechanism of sand workers after a long time can be self-repair, and even in the event of failure will not lead to a full cut, you can more customers to bring greater economic benefits for some investment to build

- Q: What are the advantages of the new sand making machine compared to the traditional sand making equipment?

- Again, in the application area, the new sand making machine equipment has a variety of crushing cavity type, can achieve "stone stone" and "stone blacksmith" two kinds of broken sanding principle of easy conversion, thus solving a machine multi- So in the current mechanism of sand and gravel material, cement, refractories, metallurgy and other industries have a wide range of applications;

- Q: What is the energy efficient sand making machine, it is the difference between its ordinary sand making machine?

- 4, vsi vertical shaft impact sander wearing parts of low consumption, while the grain is also good, in the sand machine equipment is more outstanding.

- Q: How to choose the accessories of sand making machine

- Sand making machine is an important production equipment, the destruction of parts for the production process, etc. This is inevitable, we are in the production and processing at the same time, also pay attention to the occurrence of this situation, the timely solution to this Phenomenon, paving the way for the development of production.

- Q: What is the difference between environmentally friendly hydraulic press and cement brick machine?

- Pressure vibration forming, playing out of the product strength is relatively high

Send your message to us

SAND MAKING - VSI Vertical shaft Impact crusher

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords