SAND MAKING - PCL Vertical Shaft Impact Crusher

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

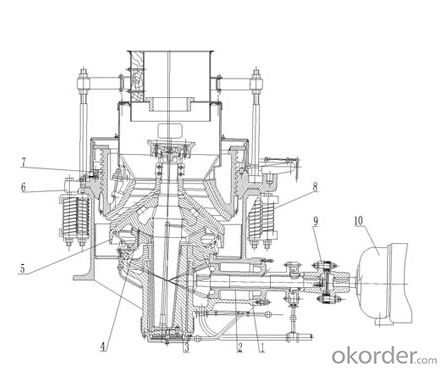

Sand Making Machine (namely PCL vertical shaft impact crusher) is of high-power and low-consumption, which is designed depending on several years’ hard work and study of mechanical mining equipment. Sand Making Machine absorbs advanced technology of the same products of Barmac Company of America, now it is of the international level. Sand Making Machine plays an important role in crushing minerals into pieces. PCL vertical shaft impact crusher is widely used in all kinds of minerals, cement, refractory material, carborundum grain, glass raw material, construction sand, stone stock and all kinds of metallurgy slag, especially carborundum, sintered bauxite, magnesite, such materials are with features of very hard and anticorrosion. And Sand Making Machine is more productive than other kind of crushers.

1.Simple structure and low operating cost;

2. High crushing ratio with low consumption;

3. Function of fine crushing and crude grinding;

4. Slightly influenced by moisture content of material, and the max moisture content is about 8%;

5. More suitable for crushing mid-hardness and hardness materials;

6. Cubic shape of final products, high density of piling up and low iron pollution;

7. More wearable and easier maintenance;

8. Low working noise (lower than 75 decibel) and light dust pollution.

The raw material enters into the PLC vertical shaft impact crusher through feed hopper and is devided into two parts by material-dividing plate. One enters into impeller through the center of material-dividing plate, be accelerated soon. The acceleration is hundreds of times than gravitational acceleration. Then the raw material is threw out from the three evenly distributed flow channels at the speed of 60-70m/s. The raw material first collides with the falling material and collides with the material liner in vortex cavity together. The raw material is rebounded by material liner and threw out to the top of the vortex cavity. The moving direction changes and deflects down. The material which is threw out from flow channels forms a continuous material liner. In this way, the material is hit, crashed and ground for twice or more times in vortex cavity. The crushed material discharges from outlet in the bottom. In the whole crushing process, the raw material is crushed by hitting with itself instead of with metal. The raw material hit, crash and crushed with material liner which reduce the pollution and extend the wear time. And the clever self-circulation of the airflow in vortex cavity eliminate dust pollution.

| Model | Rotate speed of impeller (r/min) | Max feed size (mm) | Power (kW) | Weight (including motor) (t) | Capacity (t/h) | Overall dimensions (mm) |

| PCL-600 | 2000-2600 | 30 | 2×30 | 5.6 | 10-30 | 2800×1550×2030 |

| PCL-750 | 1600-2100 | 35 | 2×45 | 7.5 | 30-50 | 3300×1800×2440 |

| PCL-900 | 1300-1700 | 40 | 2×55 | 12 | 50-80 | 3750×2120×2660 |

| PCL-1050 | 1100-1450 | 45 | 2×110 | 16 | 70-120 | 4480×2450×2906 |

| PCL-1250 | 950-1200 | 45 | 2×132 | 22 | 80-150 | 4563×2650×3176 |

| PCL-1350 | 900-1200 | 50 | 2×160 | 26 | 120-200 | 5340×2940×3650 |

- Q: What are the differences between dry sand making and wet sand making?

- The new type of sand making machine (vertical shaft impact crusher) for hardness is not higher than 320Pa soft or medium hard and extremely hard ore material broken, sand making machine is widely used in large, smelting, building materials, roads, railways,

- Q: The composition of sand making machine

- The use of automotive grease special focus lubrication, lubrication parts for the spindle assembly of the upper bearing and the lower bearing two, in order to facilitate the filling, with the tubing to the outside of the machine

- Q: Vertical sand making machine and horizontal sand making machine which is good

- Sand making equipment, there are many types of equipment, but also can be called river pebble sand machine, sand machine and other different names.

- Q: What are the advantages of the new sand making machine compared to the traditional sand making equipment?

- Again, in the application area, the new sand making machine equipment has a variety of crushing cavity type, can achieve "stone stone" and "stone blacksmith" two kinds of broken sanding principle of easy conversion, thus solving a machine multi- So in the current mechanism of sand and gravel material, cement, refractories, metallurgy and other industries have a wide range of applications;

- Q: What is the energy efficient sand making machine, it is the difference between its ordinary sand making machine?

- 1, vsi vertical shaft impact sand processing capacity, high yield, compared with the domestic similar sand making equipment, production increased by 30%;

- Q: How to choose the accessories of sand making machine

- Sand making machine is an important production equipment, the destruction of parts for the production process, etc. This is inevitable, we are in the production and processing at the same time, also pay attention to the occurrence of this situation, the timely solution to this Phenomenon, paving the way for the development of production.

- Q: What is the difference between environmentally friendly hydraulic press and cement brick machine?

- Cement brick machine, then some of the use of clay brick, clay itself is the land resources, with a large number of brick, then, certainly in the destruction of the ecological environment,

Send your message to us

SAND MAKING - PCL Vertical Shaft Impact Crusher

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords