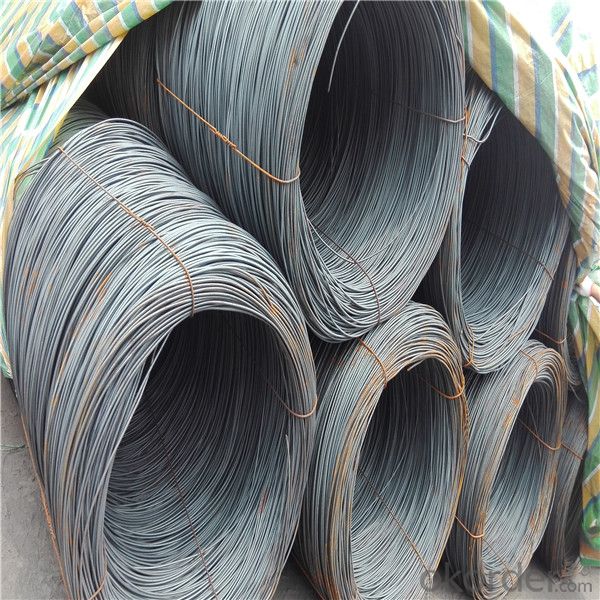

SAE1008 Steel wire rod 5.5mm-14mm low carbon

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 17645 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Produced from billets at the rolling mill, wire rod is the basis of all steel wire, rope and fencing products.

The most important characteristic in determining wire rod’s end use is its drawability. Common low carbon

wire rod is used for nails, small shaped products, barbed wires, various wire nettings, steel chains, and

other applications. High Carbon wire rod uses include steel tire cords for automobiles, conveyor belts, and

pressure hoses. Other applications include bolts, nuts, and machine parts, as well as compression, tension

and torsion springs.

Features

1、Pure steel quality, stable chemical contents, small tolerance.

2、Constant Quality, good drawing performance.

3、High dimension accuracy degree, accuracy degree of Level C up to 80%, smooth surface, less scale,

easy to be pickled.

4、Automatic bundling with 4 lines by Machine in tidy and good looks

5、Big high quality percentage, small coil percentage, and heavy coil weight for Hard Coil.

6、High sorbitizing percentage.

Product Description :

Standard | AISI, ASTM, BS, DIN, GB, JIS |

Material/steel grade | Q195-Q235,SAE1006B,SAE1006CR, SAE1008B, SAE1008CR, SAE1010B, SAE1018B, or according to customers requirements |

Wire Gauge | 5.5-12mm |

Coil weight | 1.8-2.1mts |

MOQ | 25MT |

Delivery Time | 15-30 days after receipt of L/C or deposit by T/T |

Packing | In coil and load in container, if large quantity, by bulk vessel; Can be packed as customers' special requirements |

Payment terms | 1).100% irrevocable L/C at sight. 2).30% T/T prepaid and the balance against the copy of B/L. 3).30% T/T prepaid and the balance against L/C |

Application | widely used in machinery parts, manufacturing industry, electronics industry, metal tools and others |

Application :

It generally used in braiding the hose for bathing product and machinery. With it

good flexibility, resistant to high temperature and resistant to corrosion, it

used widely in many industries.

Packing :

Hot-rolled wire rod is held in a unit with at least four steel straps in the

transverse direction and transported and stored without further packaging.

Before

the steel strapping is applied, the wire rod must be sufficiently compressed.

The strapping is fixed in the transverse direction with a single circumferential

strap so that the strapping does not slip and cause the coil to come apart.

Our service:

(1) We cooperate with famous factories with advanced equipment and well trained workers.

(2) We can provide factory price with trading company service.

(3) We continuously work on the improvement of our processes, guaranteeing

consistently high standards of quality to keep none compensation.

(4) We guarantee 24 hours response and 48 hours solution providing service.

(5) We accept small order quantity before formal cooperation.

(6) We deliver the agreed quality at the agreed time, reacting to changes in

customer wishes in a flexible way.

(7) Due to our volume and selling power, we have excellent freight rates with

shipping lines.

(8) We strive to always be fair and honest in our dealings with customers.

(9) We strive to work together with customers to achieve much more than we can

achieve alone.

(10) Through our passion and commitment we aim to be a market leader in all our

key markets. To maintain our position as market leader we must continue to add

value in all that we do.

FAQ:

1.Q: What's your MOQ(minimum order quantity)?

A: One full container, mixed acceptable .

2. Q: What's your packing methods?

A: Packed in bundle or bulk ..

3. Q: How can I buy CNBM products in my country?

A:Please send us an inquiry or email ,we will reply to you if there is distributor in your country

4. Q: Can we visit your factory?

A: Warmly welcome. Once we have your schedule, we will arrange the

professional sales team to follow up your case.

5. Q: How long does it take to get the product if i place an order?

A:With the process of your requirements,we will pack and deliver in 3

-7 days. If it is by sea shipment,it will take 15-45 days depending on different locations

- Q: How does the brittleness of steel wire rod vary with different heat treatment processes?

- Different heat treatment processes can significantly affect the brittleness of steel wire rod. These processes involve subjecting the wire rod to specific temperature and time conditions to modify its microstructure and mechanical properties. One commonly employed heat treatment process is annealing, which requires heating the wire rod to a specific temperature and then gradually cooling it. This method helps relieve internal stresses, refine the microstructure, and enhance the ductility of the wire rod. Consequently, annealed steel wire rod typically exhibits reduced brittleness and increased toughness. In contrast, quenching is another heat treatment process that involves rapidly cooling the wire rod after heating it to a specific temperature. Quenching can lead to the formation of a hardened microstructure called martensite, which can enhance the strength of the wire rod. However, this process can also elevate the brittleness of the material. As a result, quenched steel wire rod tends to be more brittle compared to annealed wire rod. Another heat treatment process, known as tempering, is often used in conjunction with quenching to mitigate the brittleness of the wire rod. Tempering necessitates reheating the quenched wire rod to a lower temperature, allowing for the redistribution of internal stresses and the transformation of some martensite into a more ductile microstructure. This process contributes to improving the toughness and reducing the brittleness of the wire rod. In conclusion, the brittleness of steel wire rod can be influenced by various heat treatment processes. Annealing generally reduces brittleness and enhances ductility, while quenching can increase brittleness while boosting strength. Tempering can then be utilized to decrease brittleness after quenching. The selection of the appropriate heat treatment process depends on the desired mechanical properties and intended application of the steel wire rod.

- Q: What are the standard dimensional accuracy requirements for steel wire rod?

- The standard dimensional accuracy requirements for steel wire rod vary depending on the specific application and industry standards. However, there are generally accepted tolerances that are followed in the manufacturing and production of steel wire rod. In terms of diameter, the dimensional accuracy requirement typically ranges within a certain tolerance limit. For example, for a specific grade of steel wire rod, the diameter may be required to be within +/- 0.10 mm, meaning that the diameter can deviate by up to 0.10 mm from the specified value. This tolerance ensures consistency in size and allows for proper fit and function in various applications. Similarly, for the length of steel wire rod, a dimensional accuracy requirement is set to ensure uniformity and compatibility. The length tolerance may be specified as +/- a certain value, such as +/- 0.5% of the specified length. This tolerance ensures that the wire rod meets the desired length requirements and can be easily incorporated into different manufacturing processes. Additionally, other dimensional parameters such as straightness, surface finish, and ovality may also have specific requirements depending on the intended use of the steel wire rod. These requirements ensure that the wire rod can be efficiently processed, formed, and used in various applications while maintaining the desired quality and performance. It is important to note that the specific dimensional accuracy requirements for steel wire rod may vary depending on the industry standards, customer specifications, and the intended application. Therefore, it is crucial to consult the relevant standards or communicate with the appropriate stakeholders to determine the precise dimensional accuracy requirements for a particular steel wire rod.

- Q: What are the main distribution channels for steel wire rod?

- The main distribution channels for steel wire rod include manufacturers, wholesalers, retailers, and e-commerce platforms. Manufacturers play a crucial role as they produce steel wire rod in various grades and sizes. They have their distribution networks to directly supply the product to wholesalers or retailers. These manufacturers often have their sales teams or agents who actively promote and sell their products to potential customers. Wholesalers are intermediaries who purchase large quantities of steel wire rod from manufacturers and then distribute it to retailers or other businesses. They typically have extensive networks and warehouses to store and transport the product efficiently. Wholesalers often offer competitive pricing and bulk discounts, making them an attractive option for retailers and businesses looking to buy steel wire rod in large quantities. Retailers are the final link in the distribution chain, selling steel wire rod directly to end consumers or small businesses. They can be specialized steel suppliers or hardware stores that carry a wide range of products. Retailers often provide convenient access to steel wire rod for customers who require smaller quantities or immediate availability. In recent years, the emergence of e-commerce platforms has significantly impacted the distribution of steel wire rod. Online marketplaces allow manufacturers, wholesalers, and retailers to reach a wider customer base and facilitate direct sales. E-commerce platforms provide convenience, quick delivery, and often offer competitive pricing, making it an increasingly popular choice for buyers. Overall, the main distribution channels for steel wire rod encompass a combination of traditional channels such as manufacturers, wholesalers, and retailers, as well as the growing prominence of e-commerce platforms in the industry.

- Q: What are the common production processes for low carbon steel wire rod?

- The common production processes for low carbon steel wire rod include heating and melting the steel, casting it into billets, hot rolling the billets into wire rod, cooling and coiling the wire rod, and finally, inspection and packing.

- Q: How is steel wire rod used in the manufacturing of cables?

- Steel wire rod is used in the manufacturing of cables as it serves as the core material for strength and support. The steel wire rod is typically drawn through a series of dies to reduce its diameter and increase its strength, resulting in a high-tensile wire. This wire is then twisted or braided together with other wires or fibers to form the cable's core, providing durability and stability.

- Q: What are the different types of wire ropes made from steel wire rod?

- Steel wire rod can be used to create various types of wire ropes, each with its own purpose and function. Some commonly used types include: 1. Galvanized Wire Ropes: To protect against corrosion in outdoor and marine settings, these wire ropes are coated with zinc using a process called galvanization. 2. Stainless Steel Wire Ropes: These wire ropes are made from high-quality stainless steel, providing exceptional corrosion resistance even in harsh conditions. They are popular in industries like marine, food processing, and pharmaceuticals. 3. Bright Wire Ropes: Also known as ungalvanized wire ropes, these ropes are made from plain steel wire rods without any protective coating. They are typically used in static applications where corrosion resistance is not a concern. 4. Plastic Coated Wire Ropes: For added protection against corrosion and abrasion, these wire ropes have a layer of plastic coating applied over the steel core. They are commonly used in applications like gym equipment and hoisting cables. 5. Compacted Wire Ropes: By compacting the strands, these wire ropes have reduced gaps between them, resulting in increased strength and durability. They are frequently used for heavy lifting operations and crane applications. 6. Rotation Resistant Wire Ropes: Designed to minimize twisting and rotation under heavy loads, these wire ropes have special strand and core configurations. They are ideal for applications like suspension bridges and tower cranes that require precise control and stability. 7. Wire Ropes with Fiber Core: These wire ropes have a core made of natural or synthetic fibers like sisal or polypropylene. The fiber core provides flexibility and cushioning, making them suitable for applications that require shock absorption, such as elevators and ski lifts. Choosing the right wire rope depends on various factors like the environment, load requirements, and intended application since each type has its own unique properties and advantages.

- Q: How is steel wire rod different from steel bars?

- Steel wire rod and steel bars are both made from steel, but they differ in terms of their shape and size. Steel wire rod is a long, thin, and cylindrical product, typically with a diameter ranging from 5.5mm to 20mm. It is primarily used as a raw material in the manufacturing of various steel products, including nails, wires, and reinforcement materials. On the other hand, steel bars are solid, straight, and usually have a larger diameter compared to wire rods. They are commonly used in construction projects as structural components, such as beams, columns, and reinforcing bars in concrete structures. Therefore, the key distinction lies in their shape and application in different industries.

- Q: What are the main factors affecting the dimensional stability of steel wire rod?

- The main factors affecting the dimensional stability of steel wire rod include the composition of the steel, the manufacturing process, and the environmental conditions during storage and use.

- Q: What are the different high-temperature properties of steel wire rod?

- Some of the different high-temperature properties of steel wire rod include high strength, good heat resistance, excellent oxidation resistance, and the ability to retain its shape and mechanical properties at elevated temperatures.

- Q: What are the different types of steel wire rod surface cleaning methods for wire galvanizing?

- There are several different types of steel wire rod surface cleaning methods that can be used for wire galvanizing. These methods are designed to remove any impurities or contaminants from the surface of the wire rod before it undergoes the galvanizing process. One common method is acid pickling. Acid pickling involves immersing the wire rod in a bath of acid solution, usually hydrochloric acid or sulfuric acid. The acid helps to dissolve any mill scale, rust, or other surface contaminants, leaving the wire rod clean and ready for galvanizing. Another method is mechanical descaling. This method involves using mechanical means, such as abrasive brushes or shot blasting, to physically remove any surface impurities from the wire rod. This method is often used for wire rods that have heavy scale or stubborn contaminants that cannot be easily removed by acid pickling alone. Additionally, there is a method called electrolytic cleaning. This method uses an electric current to remove surface impurities from the wire rod. The wire rod is immersed in an electrolyte solution, and an electric current is passed through the solution, causing the impurities to migrate away from the wire rod and towards the opposite electrode. This method is often used for wire rods that have a thin layer of oxide or other surface contaminants. Finally, there is a method called mechanical cleaning. This method involves using mechanical means, such as wire brushing or sanding, to physically scrub the surface of the wire rod and remove any surface impurities. This method is often used for wire rods that have light scale or surface contaminants that can be easily removed by mechanical means. Overall, the choice of cleaning method will depend on the specific requirements and condition of the wire rod. Each method has its own advantages and disadvantages in terms of effectiveness, cost, and environmental impact.

Send your message to us

SAE1008 Steel wire rod 5.5mm-14mm low carbon

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 17645 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords