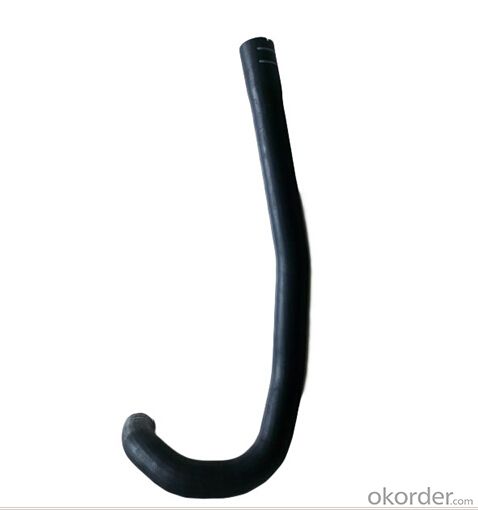

Rubber Fuel Hose High Pressure 90 Degree OEM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 50000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick details

Material: 100% pure silicone rubber+high quality polyester

Application: turbo boost/racing/tuning/intercooler/turbo/air intake/wastegate/cooling system

Thickness:4mm-6mm

Ply:3-5

Length:50mm-2000mm

ID:3mm-150mm

Color: red, blue, black, pink, purple, yellow, green, orange, white, transparent and other colors

Working Pressure: 1.2 Mpa

Bursting Pressure: 03~0.9 Mpa

Operating Temperature: -20℃ to ~ + 260 ℃

Quality Quarantee: 5 years

Packaging & Delivery

Packaging Detail: | fuel line hoses packing(5/16 inch) 80000m/container size:long 591 cm,wide5850px,high5950px. G.W:13TON |

Delivery Detail: | 15 Days |

Product Description

Construction:

Tube:Rubber with high performance on oil resistance

Reinforcement: High tensile braid of fibers

Cover: Synthetic rubber with excellent aging resistance and weather ability. Smooth surface, concave-convex surface and cloth covered

Temparature Range:-40°C~+110°C

Specification:

NO | I.D | Refer to O.D | Working pressure | Burst pressure | approximate Weight | |||||

(inch) | (mm) | (inch) | (mm) | MPa | Psi | MPa | Psi | kg/m | lbs/ft | |

1 | 1/8 | 3.2±0.2 | 0.35 | 9±0.3 | 2.06 | 300 | 8.27 | 1200 | 0.078 | 0.12 |

2 | 5/32 | 4±0.2 | 0.4 | 10±0.3 | 2.06 | 300 | 8.27 | 1200 | 0.092 | 0.14 |

3 | 3/16 | 4.8±0.2 | 0.43 | 11±0.3 | 2.06 | 300 | 8.27 | 1200 | 0.108 | 0.16 |

4 | 1/4 | 6.3±0.3 | 0.5 | 12.7±0.3 | 2.06 | 300 | 8.27 | 1200 | 0.134 | 0.2 |

5 | 5/16 | 8.0±0.3 | 0.56 | 14±0.3 | 2.06 | 300 | 8.27 | 1200 | 0.147 | 0.22 |

6 | 3/8 | 9.5±0.3 | 0.63 | 16±0.4 | 2.06 | 300 | 8.27 | 1200 | 0.182 | 0.27 |

7 | 15/32 | 12±0.3 | 0.75 | 19±0.5 | 2.06 | 300 | 8.27 | 1200 | 0.238 | 0.35 |

8 | 1/2 | 12.7±0.4 | 0.78 | 20±0.5 | 2.06 | 300 | 8.27 | 1200 | 0.262 | 0.39 |

9 | 5/8 | 16±0.4 | 0.94 | 24±0.5 | 1.03 | 150 | 4.12 | 600 | 0.351 | 0.52 |

10 | 3/4 | 19±0.4 | 1.13 | 28.8±0.5 | 1.03 | 150 | 4.12 | 600 | 0.515 | 0.77 |

11 | 1 | 25.4±0.5 | 1.38 | 35±0.6 | 1.03 | 150 | 4.12 | 600 | 0.637 | 0.95 |

Our Services

We can offer OEM Services

We can provide FREE SAMPPLE for our customers

We can crimp hose assembly for our customers.

We welcome clients to visit our factory leading to better understanding of our production.

FAQ

Q1. Do you produce smooth or cloth wrapped cover?

A. Both, we can produce both cover, which depends on customer’s request.

Q2. Do you produce embossed marking?

A. Yes, we do provide embossed and printing markings with different color.

Q3. Can you produce product with my own brand?

A. Yes, we have been offering OEM services for 20 years.

Q4. Does your product have different color hose?

A. Yes, we currently provide black, grey, red, blue and yellow.

Q5. How long does my order take to be delivered?

A. It usually takes 5 to 30 days, which generally depends on the quantity of your order and our storage.

- Q: What are the production processes and characteristics of high pressure rubber hose?

- High pressure wire braided hose production process: rubber, rubber mixing, extrusion, heat pipe casing (core casing, silicone oil and then wipe) molding glue, woven wire (wire stranding), package glue, water reel cloth, cloth, water solution of vulcanization, mandrel stripping, cutting head, pressure test and inspection packaging and warehousing.

- Q: SolidWorks how do you put rubber hose on the iron pipe?

- It is important to note that different materials are assigned to each other: metal and rubber. To produce engineering drawings that guide production, fill in the corresponding section lines on the cutaway surface.

- Q: How can I keep the rubber tube for stethoscope?

- I don't think this question should be considered purely from the point of view of sound transmission.

- Q: The difference between hose and rubber tube

- Latex tube is characterized by good elasticity, general tensile range of 6-9 times its own, back to stretch 100%. The rubber tube has the characteristics of oil resistance, acid and alkali resistance, heat resistance and pressure resistance, and attracts rubber pipes. It is mainly used in industry, mine, civil transportation and suction of liquids, gases and so on.Latex tube is generally used in hospitals, equipment factories, power plants, scientific research laboratories and other fields, but also related to bungee jumping, trampoline and other places of entertainment. Rubber tubes are mainly used in industry and agriculture. Latex tube is not resistant to oxidation and corrosion, and rubber tube has one of the characteristics, so its scope of application is more extensive.

- Q: What happened to the soft rubber flat?

- A slightly heated or pressurized medium will return to its original condition.

- Q: Classification of metal hoses

- The metal hose is an important connecting component in engineering technology. It is made up of corrugated flexible pipe, net sleeve and joint. In all kinds of gas and liquid pipeline system, length, temperature, position and angle compensation system as the compensation element, a sealing element and connecting element and damping element, used in various fields of aerospace, petrochemical, electronics, shipbuilding, mining machinery, textile, medical electronic energy construction etc.. The latest national standard for metal hose is the general specification for corrugated metal hose (GB/T14525-2010), which was implemented in October 1, 2011.

- Q: What are the properties of an oil resistant rubber hose?

- The performance of the extended product is accompanied by a rubber hose in life in many areas already occupy a crucial position, which makes the hose detection is important, especially for the rubber pipe detecting water, oil and gas and other purposes.

- Q: What's the cause of a default like a general rubber product?

- Rubber aging is a common problem of rubber products, and aging is mainly due to internal structure or component is easy to aging due to weakness, such as unsaturated double bond, branched, carbonyl, hydroxyl and so on; at the end, the main external or environmental factors are sunlight, oxygen, ozone, heat, water and mechanical stress force, high energy radiation, electricity, industrial gas, water, salt fog, fungi, bacteria, insects etc..

- Q: Faucet hose connection problem

- The buried water pipe is outside the wire, you can use the inner home angle valve. When installing, pay attention to the rubber ring in the metal hose. The gasket should be put away. It is better to buy the transparent rubber ring and the metal hose of that kind of gasket, and pay attention to the length.

- Q: How to identify the quality of rubber pipes for sewage treatment?

- The general hose inside and outside the adhesive layer material with natural rubber, styrene butadiene rubber or butadiene rubber; hose with chloroprene rubber, nitrile rubber; acid and alkali resistant, high temperature resistant hose with ethylene propylene rubber, fluorine rubber or silicone rubber etc.. Structure: hose structure is usually divided into inner layer, outer layer and skeleton layer (or middle layer). The inner layer directly bears the abrasion and erosion of the conveying medium; the outer rubber layer protects the inner part of the hose from the damage and erosion of the external environment; the stock price is the pressure bearing layer of the rubber tube, and gives the strength and rigidity of the tube body. The working pressure of the hose depends on the material and structure of the skeleton.

Send your message to us

Rubber Fuel Hose High Pressure 90 Degree OEM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 50000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords