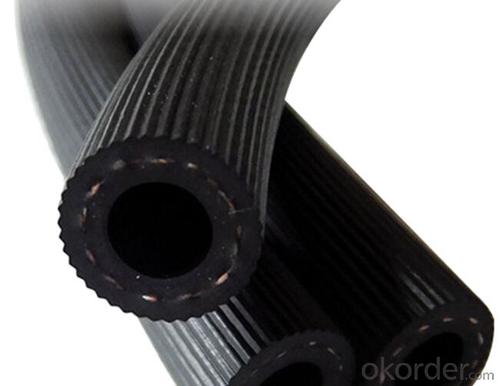

Rubber Fuel Hose High Pressure Reinforced OEM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m

- Supply Capability:

- 50000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick details

Product Category: | Hydraulic Rubber pipe | Business Type: | Manufacture | Material: | Synthetic Rubber & Steel Wire |

Inner Tube: | Nitrile | Reinforcement: | Two braided layer of high tensile steel wire | Cover: | Neoprene Blend |

Temperature range: | -40°C to 120°C | Surface option: | Smooth or Cloth Wrapped surface | Color Option: | Black, Red, Blue, Yellow and so on |

Applications: | Coal / Mining / Agricultural machine / |

Packaging & Delivery

Packaging Detail: | fuel line hoses packing(5/16 inch) 80000m/container size:long 591 cm,wide5850px,high5950px. G.W:13TON |

Delivery Detail: | 15 Days |

Product Description

Construction:

Tube:Rubber with high performance on oil resistance

Reinforcement: High tensile braid of fibers

Cover: Synthetic rubber with excellent aging resistance and weather ability. Smooth surface, concave-convex surface and cloth covered

Temparature Range:-40°C~+110°C

Specification:

NO | I.D | Refer to O.D | Working pressure | Burst pressure | approximate Weight | |||||

(inch) | (mm) | (inch) | (mm) | MPa | Psi | MPa | Psi | kg/m | lbs/ft | |

1 | 1/8 | 3.2±0.2 | 0.35 | 9±0.3 | 2.06 | 300 | 8.27 | 1200 | 0.078 | 0.12 |

2 | 5/32 | 4±0.2 | 0.4 | 10±0.3 | 2.06 | 300 | 8.27 | 1200 | 0.092 | 0.14 |

3 | 3/16 | 4.8±0.2 | 0.43 | 11±0.3 | 2.06 | 300 | 8.27 | 1200 | 0.108 | 0.16 |

4 | 1/4 | 6.3±0.3 | 0.5 | 12.7±0.3 | 2.06 | 300 | 8.27 | 1200 | 0.134 | 0.2 |

5 | 5/16 | 8.0±0.3 | 0.56 | 14±0.3 | 2.06 | 300 | 8.27 | 1200 | 0.147 | 0.22 |

6 | 3/8 | 9.5±0.3 | 0.63 | 16±0.4 | 2.06 | 300 | 8.27 | 1200 | 0.182 | 0.27 |

7 | 15/32 | 12±0.3 | 0.75 | 19±0.5 | 2.06 | 300 | 8.27 | 1200 | 0.238 | 0.35 |

8 | 1/2 | 12.7±0.4 | 0.78 | 20±0.5 | 2.06 | 300 | 8.27 | 1200 | 0.262 | 0.39 |

9 | 5/8 | 16±0.4 | 0.94 | 24±0.5 | 1.03 | 150 | 4.12 | 600 | 0.351 | 0.52 |

10 | 3/4 | 19±0.4 | 1.13 | 28.8±0.5 | 1.03 | 150 | 4.12 | 600 | 0.515 | 0.77 |

11 | 1 | 25.4±0.5 | 1.38 | 35±0.6 | 1.03 | 150 | 4.12 | 600 | 0.637 | 0.95 |

Our Services

We can offer OEM Services

We can provide FREE SAMPPLE for our customers

We can crimp hose assembly for our customers.

We welcome clients to visit our factory leading to better understanding of our production.

FAQ

Q1. Do you produce smooth or cloth wrapped cover?

A. Both, we can produce both cover, which depends on customer’s request.

Q2. Do you produce embossed marking?

A. Yes, we do provide embossed and printing markings with different color.

Q3. Can you produce product with my own brand?

A. Yes, we have been offering OEM services for 20 years.

Q4. Does your product have different color hose?

A. Yes, we currently provide black, grey, red, blue and yellow.

Q5. How long does my order take to be delivered?

A. It usually takes 5 to 30 days, which generally depends on the quantity of your order and our storage.

- Q: Could you tell me the maximum pressure that the hose can bear?

- It doesn't make any sense because there is no higher hydraulic pump that can work above 35MP. Of course, there is a super high-pressure hydraulic hose, the working pressure of up to 80MP., using 6 layers of steel wire or more winding process.

- Q: SolidWorks how do you put rubber hose on the iron pipe?

- This is to be made into an assembly. First, parts, iron pipes and rubber pipes are made separately, and then the assembly is made to fit together.

- Q: What kinds of pipe joints can be divided into? What are the differences between the so-called one - piece pipe joint and other types of pipe joint?

- The integral type is a pressure hose, and the hose joint is mostly of two parts, and the integral part combines the two parts together

- Q: My company does high-quality rubber tube, all of the core method, and why use EPDM to do the inner tube, it is difficult to take off the core, please point out! What's the reason?

- The core needs to be removed, and if it is too long, the mandrel can be divided into two sections and separated from the 2 sides

- Q: Will the outside of the brake hose of the car burst apart?

- If the brake oil pipe (you should be the brake hose) is best, I'd recommend replacing him

- Q: How do you remove the burrs on the rubber joint quickly?

- Frozen deburring machine is a kind of ultra low temperature using liquid nitrogen to make rubber, plastic products, zinc alloy burr occurs rapidly embrittlement, and under this condition, the burr of high-speed jet impinging particles of frozen products, so as to achieve both high quality and high efficiency removal products of burr, and keep possession the product itself does not change. The utility model can greatly improve the deburring precision of products, and has a high degree of intensification.

- Q: Hydraulic hose joint configuration

- Gas safety hose joint: a joint security guarantee gas transmission, including metal hose, Baotou, connecting pipe and a connecting nut, one end of the connecting pipe and hose, metal hoop pressure Baotou into one, the other end is connected with the inner hole of flange nut for different aperture of two parts, large hole diameter is slightly larger than the connection the flange is provided with internal thread, big hole depth is larger than the thickness of flange, hole diameter is slightly larger than the connecting pipe outer diameter and smaller than the outside diameter of the flange.

- Q: Will the electric water heater be well connected with metal hose or hose?

- The electric water heater, now in the industry are required to use PPR on the inlet and outlet pipe welding, a long service life, can effectively control the water heater outlet Water Leakage; on the other hand, can avoid the water heater power switch for two grounding and frequent take-off effectively. Therefore, the metal pipe connection does not meet the safety and installation specifications

- Q: How can the rubber tube be used properly and how to use it properly?

- Due to the aging hose burst of high temperature oil. Operation engineering machinery, hydraulic system for power loss and oil heating, and the influence of the outside temperature (especially in summer), the sharp increase in oil. The oil using high temperature, banana aging, elastic variation, decline the strength and sealing performance, the hose will soon burst. Therefore, during the operation, when the hydraulic system temperature is too high, too fast, should identify the reasons, be excluded; summer homework, especially in continuous operation, should take necessary measures to cool down.

- Q: The selection of valves and fittings has the following requirements

- The joint of the valve is threaded with an internal thread, so that the connection in the installation is easier to select transition joints.

Send your message to us

Rubber Fuel Hose High Pressure Reinforced OEM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m

- Supply Capability:

- 50000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords