RQ-S3 High Strength Micro Steel Fiber

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

RQ®-S3 High Strength Micro Steel Fiber

RQ®-S3 high strength micro steel fibers are made by steel wires under a certain condition,

which with tensile strength larger than 2900MPa. The steel fibers have excellent properties and

can get high anchoring force with cement-based materials, which can reduce the propagation of

micro-cracks due to plastic shrinkage, dry shrinkage and thermal stress. RQ®-S3 high strength

micro steel fibers can also prevent the formation and propagation of macro-cracks. The steel fibers can improve the ability of concrete by fracture resistance, tensile property, shearing

resistance,bending resistance, abrasion resistance, impact resistance and fatigue resistance. The

steel fibers are suitable for ultra high strength fiber reinforced cementitious composites and

reactive powder concrete.

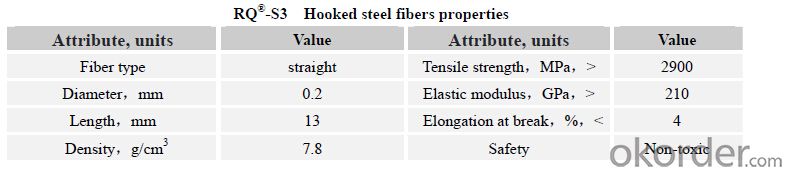

*The main technical performance and characteristics

* Excellent mechanical properties. After a cold drawing process, the tensile strength of

RQ®-S3 Micro steel fibers can reached 2900MPa to make concrete with excellent mechanical

properties.

* Excellent corrosion resistance. With copper plating on surface of micro steel fibers,

RQ®-S3 Micro steel fiber reinforced concrete has excellent corrosion resistance.

*Improvement of crack resistance. RQ®-S3 micro steel fibers can stop or retard the formation and development of the original cracks. The fibers can also reduce the formation of cracks caused by plastic shrinkage, and inhibit the formation and propagation of macro cracks.

* Improve mechanical properties. Under a dosage of 1-2% by volume of RQ®-S3 micro steel fibers, the tensile strength, compressive strength and bending strength can be increased

separately by above 100%, 10~25% and 60~120%.

*Usage and notes:

* Dosage: Common dosage of 20~312kg/m3 (corresponding to the volume dosage of 0.25~4%).

* Material requirements: Sea water, sea sand and chloride must not be used in steel fiber

reinforced concrete.

* Mixing:The workability of steel fiber reinforced concrete could be determined by referring to the slump of common concrete. The mixing time should be extended to obtain a good dispersion.

* Curing: The steel fiber reinforced concrete (or cement) and common concrete (or cement) with the same construction and curing process.

* Safety in use: Appropriate protection should be taken in case of stabbing and splashing into the eyes.

*Application range

Widely used in the highway pavement, bridge, tunnel, industry floor, airport pavement, building structure, underground engineering, underwater engineering, water -proof engineering, hydropower station, harbor pavement,military engineering and all kinds of concrete prefabricated.

*Packaging

Paper package with 25kg/bag (or customized). The packages should be sealed in a cool and dry

place. Waterproof should be ensured during transportation. Shelf life is one year. Handling and

transportation is very convenient.

*After-sale Service

To ensure the engineering units quality and improve the level of civil construction technology, thecompany will provide free technical advice and technical services with more than provide concrete mix suggestions and related on-site technical guidance.

Send your message to us

RQ-S3 High Strength Micro Steel Fiber

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords