Roofing Aluminum Sandwich Panel with Best price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Roofing Aluminum Sandwich Panel Description:

Roofing Aluminum Sandwich Panel are used in those applications where high structural rigidity and low weight is required. An evident example of use of sandwich panels is aircraft where mechanical performance and weight saving is essential. Other applications include packaging (e.g. fluted polypropylene boards of polypropylene honeycomb boards), transportation and automotive as well as building & construction.

Aluminum Sandwich Panel is mainly used for external and internal architectural cladding or partitions, false ceilings, signage, machine coverings, container construction etc. Applications of ACP are not limited to external building cladding, but can also be used in any form of cladding such as partitions, false ceilings etc. ACP is also widely used within the signage industry as an alternative to heavier, more expensive substrates.

2.Main Features of the Roofing Aluminum Sandwich Panel :

Excellent coating;

High 180°C Peel strength;

High strength;

Color uniformity and durability;

Excellent insulation of termal conductivity;

Excellent products.

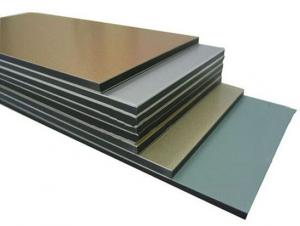

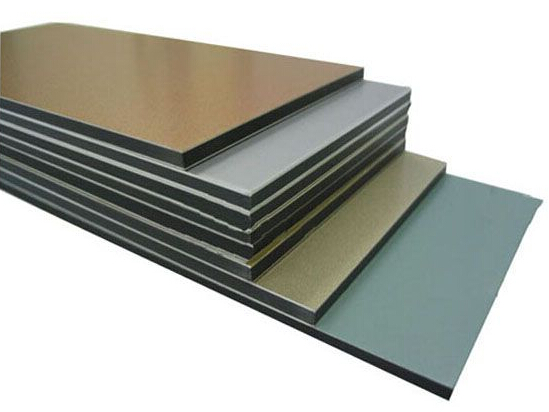

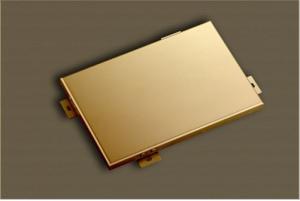

3. Roofing Aluminum Sandwich Panel Image:

4. Roofing Aluminum Sandwich Panel Specification:

Width | 1220mm, 1250mm, 1500mm |

Length | 2440mm or customize |

Total thickness | 2mm, 3mm(interior use), 4mm(exterior use), 5mm, 6mm |

Aluminium skin thickness | interior use:0.04, 0.06, 0.08, 0.10, 0.12, 0.15, 0.18mm |

Aluminium skin thickness | exterior use:0.21, 0.25, 0.30, 0.35, 0.40, 0.45, 0.50mm |

Nonstandard dimensions could be customized.

5.FAQ:

1). How to confirm the color for what you want?

You can contact me for our color card.You can also choose a color from the RAL/Panton color card.

2).What are your certificates?

ISO, CE, SGS certificates

3). How to confirm the color for what you want?

You can contact me for our color card.

You can also choose a color from the RAL/Panton color card

- Q: In the curtain wall applications, aluminum veneer and aluminum plate which is better?

- Combined with the current mainstream of the curtain wall material, aluminum veneer will be better, after all, from the cost, technology, and the effect, recycling and so have a remarkable place.

- Q: I was ordered to OKorder-made aluminum-plastic plate production, long-term Gong Geng in the capital, because the market "hair with" here, find eye

- East building materials are, a lot of!

- Q: Yueyang where to buy aluminum-plastic plate, which the market has aluminum-plastic plate sales

- December Xunyi mechanical and electrical market part of the shops opened, when the major hardware and mechanical have. Now you can go to the sun bridge big market or Dongting Building.

- Q: 3d board and aluminum plate prices? What kind of price?

- Three-dimensional board, including polymer composite board, aluminum plate, color plate and other molding materials, in general, polymer composite board, aluminum plate are in the price is higher than the aluminum-plastic plate.

- Q: OKorder 3M glass curtain wall adhesive tape and aluminum-plastic plate Lvkou Ban and aluminum veneer special double-sided tape where there?

- US 3M company in OKorder designated agent 3M tape and glue labels and other products distribution and double-sided tape cutting and precision cross-forming! My company's tape has a professional curtain wall with double-sided adhesive.

- Q: How is Allegro embossed aluminum-plastic plate is an aluminum-plastic plate, who can describe in detail?

- Athena embossed aluminum-plastic plate is the use of coated aluminum plate by a special fine process to suppress a variety of convex and convex pattern of aluminum.

- Q: How to sell aluminum and plastic

- Waste boards and side materials are meeting in the machine to crush and sort, separate sell, plastic re-granulation, see inside the content and the number of filled to fill, generally more than 2,000 tons

- Q: I want to find a single aluminum aluminum-plastic plate manufacturers, has been unable to find, I hope you know the squeaky sound, it is best to leave the phone or address, thank you! The

- Often outdated products

- Q: What is the aluminum plate and what features

- Aluminum-plastic composite panels can be divided into outdoor, indoor with two, and then can be divided into fire and general type. Now the market is a large number of sales are general type. Outdoor aluminum-plastic composite panels are up and down are O. 5mm aluminum (usually pure aluminum), the middle sandwich for the PE (polyethylene) or PVC (polyvinyl chloride), sandwich thickness of 3-5mm. Fireproof aluminum-plastic composite panel for the middle of the FR (fire plastic). Outdoor composite aluminum composite panel thickness of 4-6mm. Indoor use of aluminum-plastic plate is generally 0.2-O.25mm aluminum plate, sandwich thickness of 2.5-3mm, indoor aluminum plate thickness of 3-4mm. The standard specification for aluminum-plastic board products is generally 1220 (W) x 2440 (L) x thickness, and the width can also reach 1250 or 1500mm. Outdoor often used the thickness of the thinnest should be 4mm, indoor thickness stress 3mm.

- Q: Silver aluminum plate is what material is not silver aluminum plate?

- According to the current building facade commonly used materials to judge, it should be said that aluminum is a class, either aluminum or plastic plate, or according to the pronunciation, it should be said that there may be aluminum veneer. There is something close to carbon.

Send your message to us

Roofing Aluminum Sandwich Panel with Best price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords