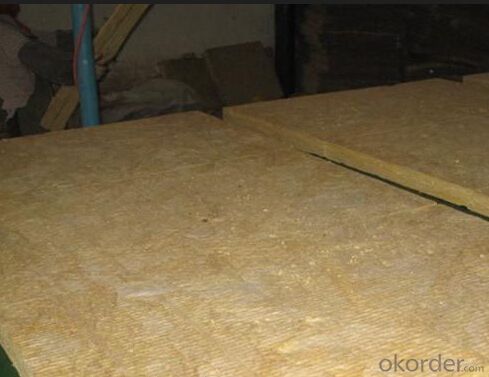

Ceramic Fiber Board - Rockwool Fiber Wool Board Cmax-4

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Rock Wool Sandwich Panel

:It sets fire prevention, thermal insulation, sound insulation and noise reduction and beautiful decorative in one.

Product Introduction:

Board sets fire prevention, thermal insulation, sound insulation and noise reduction and beautiful decorative in one,is the ideal choice for building external wall panel, level, smallpox, internal partition wall

Product Application:

1,Incapable of corroding the building components made of steel, aluminum ect.

2,Excellent thermal insulting and heat preserving functions, outstanding heat absorptivity , which can increase thermal resistance value of external wall of buildings, reduce energy consumption, energy saving and emission reduction.

3,Light weight, easy to cut and processing. Can make to order extra wide, exceed wide products to use special span needs.

4,Applicable to flat, smooth and functional sandwich panels, with flat surface and stable size.

Specification:

Length(mm) | Width(mm) | Thickness(mm) | Density(kg/m3) |

1200 | 600 | 30 | 90—180 |

1200 | 600 | 40 | 70—180 |

1200 | 600 | 50 | 60—180 |

1200 | 600 | 60 | 60—180 |

1200 | 600 | 70 | 60—180 |

1200 | 600 | 80 | 60—180 |

1200 | 600 | 90 | 50—170 |

1200 | 600 | 100 | 50—150 |

1200 | 600 | 110 | 50—130 |

1200 | 600 | 120 | 50—130 |

1200 | 600 | 130 | 50—120 |

1200 | 600 | 140 | 50—100 |

1200 | 600 | 150 | 50—100 |

Technical Parameters:

Properties | Unit | Estimated Value |

Thermal Conductivity | W/mk | <0.004 |

Fiber Diameter | um | 4.8±1 |

Slag ball Content | % | <5 (grant size:>0.25mm) |

Melting Point | °C | >1000 |

Hydrophobic Rate | % | >99 |

Fire Performance | — | Incombustible class A1 |

Acidity Coefficient | — | >1.8 |

Dimensional Stability | % | <1.0 |

Compressive Strength (deformation 10%) | Kpa | >50 |

Tensile Strength | Kpa | >15 |

The quality of moisture absorption rate (50°C, RH 95%, 96h) | % | <1.0 |

Short-term water absorption (10mm, 24h) | Kg/m2 | <0.5 |

FACTORY:

- Q: What method should be used to measure the thermal conductivity of fiberboard?

- It is concluded that the test error of this method and device is about 2%. This filament ultra light aluminum silicate fiber product: the filament ultra light aluminum silicate product is by Shandong Zibo high quality burnt precious stone as raw material, passes through the smelting furnace, the rejection silk, blows the cotton, the auxiliary mold and so on to deliver the work procedure. Therefore, the thermal conductivity of fiberboard is chosen by heat flow meter method.

- Q: What are the standards for ceramic fiber boards?

- Ceramic fiber board is made of continuous production, water production line and advanced technology, ceramic fiber board produced with smooth surface, accurate size, good toughness, can be arbitrarily cut, good insulation effect and other performance characteristics.

- Q: Ceramic fiber plate and aluminium silicate plate are chosen as lining materials

- Volume density is low: the density of the ceramic fiber lining is about 25% of the lining of the light heat insulation brick, about 10% of the lining of the light pouring material; adopting the fiber lining can greatly reduce the steel structure load of the furnace and prolong the service life of the furnace lining.

- Q: Refractory insulation board, pressure plate, nano heat transfer plate, calcium silicate board and ceramic fiber board, which is good?

- Ceramic fiber boardCeramic fiber board product categories:1260 standard ceramic fiber board sygx-264 1260 high purity ceramic fiber board sygx-3641400 zirconium ceramic fiber board sygx-564 1400 high alumina ceramic fiber fire plate sygx-464D1400 zirconium ceramic fiber fire baffle sygx-564D

- Q: What are the sound-absorbing fiber boards?

- Ordinary materials have sound-absorbing effect, just how much difference. And when it comes to sound-absorbing board, we are only sound-absorbing coefficient of more than 0.3 of the material known as sound-absorbing material.

- Q: What is the difference between ceramic fiber board and nano ceramic fiber board?

- The nano ceramic fiber board through the introduction of nanotechnology, the special production process, product performance has been greatly improved, high strength, low thermal conductivity, good heat insulation performance, energy saving effect is obvious, which improves the safety of the furnace, and in high temperature and high pressure conditions, can also play a good performance the product.

- Q: What are the specifications of the ceramic fiber board?

- Ceramic fiber board, also known as aluminum silicate or refractory fiber, including ceramic fiber blanket, ceramic fiber, ceramic fiber fireproof plate (plate).

- Q: What are the differences between nano ceramic plate and ceramic fiber board?

- Nano ceramic plate for ceramic fiber with insulating board (felt), it is a functional material with excellent properties of aerogel insulation material and has a heat shielding function, adaptation to adhesive and a variety of inorganic elements in high temperature ceramic fiber as reinforcing material, through a special process preparation.

- Q: What are the uses of ceramic fiber boards?

- According to the conditions of use, can be divided into:Fire dragon high purity ceramic fiber fire block HLGX-364DThe dragon high alumina ceramic fiber fireproof plate HLGX-464D

- Q: How much pressure can the ceramic fiber board withstand?

- Ceramic fiber fireproof plate, the density of 350-400Kg/m ceramic fiber board, fand; density above fand 400Kg/m.

Send your message to us

Ceramic Fiber Board - Rockwool Fiber Wool Board Cmax-4

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords