Rear-Loading Refuse Vehicle,Evironmental Sanitatiopn Equipmeng

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 10 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Profile

Rear-loading refuse vehicle is designed for loading and transporting of spongy garbage. Rear-loading refuse vehicle manufactured by our company is a kind of professional truck,which is mainly used to collect, transport and unloading the garbage in gags, dust bin and bulk non-living garbage in cities and towns.

Functions of the vehicle

The garbage is pushed into the truck bed by vehicle-mounted garbage thruster(also known as negative pressure mechanism), which can made the garbage have a higher density and distribute in the truck bed uniformly till it is filled up. The adopted collection and transportation method of the rear-loading refuse vehicle is used widest at now. All of the functions of the rear-loading refuse vehicle are drought by automobile engine by means of hydraulic mechanism in manual or electronic control.

The truck van, loader(known as hopper) and sewage box adopts to high-quality carbon steel plate with fully sealed welded structure , which has the advantage of high strength, light weight and without secondary pollution.

Technical characteristic

1.The above structures of the total vehicle are weld with high quality steel plate. The van is cove with beautiful appearance and superior performance

2.The operational control devices are separately mounted in the cab and the rear of the vehicle. 3.The operator can control the loading and compression of garbage in the rear of the vehicle. In the cab, the lifting of negative pressure mechanism and pushing and unloading of the garbage can be controlled.

4.The hydraulic system adopts to electronic control and hydraulic control, which has the combined control system including electronic, gas and hydraulic.

5.Electronic control system adopts to PLC. It can realize automatically control the engine output in the progress of compression. Also, the idling and accelerating situation can be chose automatically, which can avoid power lose of vehicle.

6.Lifting cylinder of tramper has the function of self-locking. On the side of the tramper, there equipped with emergency stop button separately, which can stop the compressing devices at casual palace.

7.The rear-loading refuse vehicle has the performance of safety and reliability.

It can satisfy the different requirements of the clients. The users can choose different overturning mechanisms of dust bin in line with various requirements.: standard ironed dust bin( 300L), plastic dust bin ( 240L、660L、1100L),the small garbage hopper installed on the vehicle (800L), the sealed and covered garbage hopper (1400L), the big garbage hopper(3350L) and etc.

Technical specification

Type | WTZ5070ZYS | WTZ5160ZYS | WTZ5250ZYS |

Boundary size(mm) | 6915X1980X2470 | 8580X2500X3100 | 9885X2500X3450 |

Total weight(kg) | 7300 | 15800 | 25000 |

Type of chassis | QL1070A5HAY | DFL1160BX1V | DFL1250A13 |

Type of chassis engine | 4KH1-TCG51 | ISD210-50 | ISD245-50 |

Power of chassis engine(KW) | 88 | 155 | 180 |

Standard of chassis engine emission | National standard Ⅴ | National standard Ⅴ | National standard Ⅴ |

Wheel base(mm) | 3360 | 4500 | 4350+1350 |

Volume of mating van(m³) | 7.2 | 13.6 | 17 |

Pressure of hydraulic system(MPa) | 16 | 16 | 16 |

Control method | automatic、manual | automatic、manual | automatic、manual |

Max.speed(km/h) | 95 | 90 | 90 |

Working Principle

When the stuffing bin is full of rubbish, the scraper opens and the skateboard moves along with the scraper run into garbage to break and first time compression; after that, the scraper is turned forward to compact rubbish; when the scraper is in place, move upward with the slide board. Compact and load the rubbish into the garbage bin and then back to the starting position.

Automatic control for the whole work process, when the garbage is continuously pressed and pressed, the push shovel under the press pressure overcome the back pressure step back to achieve the bidirectional compression to garbage till to fill the garbage bin. When the garbage truck gets rid of the rubbish in the process (or when landfill), lifts the filler, pushes the shovel back, and pushes the rubbish out of the garbage bin horizontally.

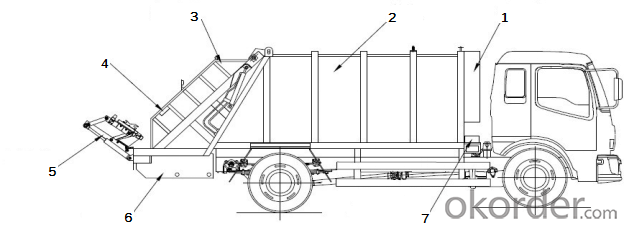

Overall drawing

1. Hydraulic fuel container 2.Box 3.Bucket lifting mechanism 4.Rear bucket control panel/Operation indicator board 5.Bucket turnover mechanism 6.Bilge tank 7.Handle operation/Operation indicator board

Necessity of Rear-loading refuse vehicle

At present, the total annual output of municipal solid waste (MSW) in China has reached 1.8 tons, and it is still increasing( annual growth rate of 8% to 10%.) With the continuous expansion of urban construction scale and the improvement of people's living standard, the composition of municipal solid waste has changed greatly. The main features of change are: the garbage density is decreasing and the compressible rate is increased. If continue to use the conventional garbage transportation, its easy to cause the load loss of garbage in the transfers, and reducing efficiency. Another hands, the suburbs can be used to landfill are less then before, people have to consider setting up garbage disposal sites in suburban areas where far from the city. According to statistics, garbage treatment plants are more than 50km far to urban areas in several major cities in China, transport costs account high proportion of garbage disposal costs. In some developed countries, transportation costs have accounted for more than 80% of the cost of garbage disposal. Therefore, to reduce the garbage collection fee is the key to reduce the city garbage disposal fees, garbage compression can solve the payload problem of garbage transport, lower transport costs is the way to collect garbage of city. Therefore, the advantage of rear-loading refuse vehicle is obvious day by day, and the efficient garbage compression transportation mode has made great progress.

Rear-loading refuse vehicle is one of the common structural type, which is composed of an automobile chassis, a filler, a cabinet body and a discharge plate mechanism. The rear-loading refuse vehicle’s characteristic is increasing the loading capacity of the garbage and improving the sealing capacity of the vehicle; better classification of garbage and it will good for environmental protection.

Send your message to us

Rear-Loading Refuse Vehicle,Evironmental Sanitatiopn Equipmeng

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 10 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords