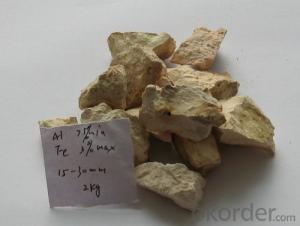

Raw Materials for Refractory:Calcined Bauxite (Aluminum-Containing 60%-65%) for Shaft Kiln, Rotary Kiln, and Round Kiln Applications

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Shape: | Lump | Dimensions: | 25kg/Bag | Chemical Composition: | Al2O3 60-65% |

| Moisture (%): | 0.5% | Al2O3 (Min): | 60%-65% | Place of Origin: | Shanxi, China (Mainland) |

| Brand Name: | CNBM | Model Number: | GYBL | Product name: | high quality bauxite aggregate |

| Product Usage: | Aluminum industry, precision casting | Refractory temperature: | 1770~2000℃(℃) | Grade: | A |

| Thermal conductivity at room temperature: | 0.03 | Elongation at break: | 1 | Bent at low tempreture: | ≤ 95 |

Packaging & Delivery

| Packaging Details: | 25kg/Bag or per customer request. |

| Delivery Detail: | 14 days |

Direct selling bauxite (aluminum-containing 60% -65%) clinker,shaft kiln/rotary kiln/round kiln calcined bauxite

Our factory specializing in the production of various types of bauxite.Aluminum content of 65%, 70%, 75%, 80%, 85%, 88%,size is customized, if need,welcome new and old customers to consult!

Our Service:

1. Your inquiry related to our products or prices will be replied in 24hours.

2. Manufacturer with large capacity, ensure the fast production cycle after confirmed the order.

3. Our professional technicians will answer your entire enquiry in patient.

4. To meet the refractory solutions, we can serve as your instructions.

5. Protection of sales area and private information for our entire customer.

If you’ve kind enquiries, please don’t hesitate to let us know. ^_^

- Q: Does the production of refractory belong to advanced technology?

- Refractories production is advanced technology supported by the state. The refractory enterprise is high-tech enterprises and it needs to apply for it in science and technology bureau.

- Q: What is the function of refractory in ceramics?

- In addition, the quality of refractory determines the finish and color of ceramic glaze.

- Q: What is the most reasonable drying heating curve of magnesia refractories? Products of less than 0.5T

- You'd better oxidize magnesia preformed unit at room temperature for a longer period of time, then bake it, during which, it's enough to control the maximum temperature within 300 degrees. During the middle process, usually heating up for 4 hours and keep warm for 3 hours. The entire heating up process takes about 20 hours. If it is the site operation magnesia-based castable, it should be heated slowly in the early stage, and pay attention to keeping warm at 80 degrees Celsius. Every manufacturers has their own heating curves, so do not blindly adopt existing curves, try to make your own heating curve.

- Q: What is high alumina refractory?

- It refers to inorganic non-metallic material with refractoriness of higher than 1580℃. Refractoriness refers to the celsius temperature that the cone-shaped refractory sample without load can resist, and under which the sample won't soften and melt down. Refractory material appears together with high temperature technology, and roughly dates from the Middle Bronze age. In the Eastern Han Dynasty (AD25~AD220) of China, fireclay refractories has been used as furnace refractories and saggers for making porcelains. In the early 20th century, refractory material develops toward the direction of high purity, high dense and ultra high temperature products, and meanwhile unshaped refractory and refractory fiber with no need of firing at all and with low energy consumption appear.

- Q: How many refractories are there for boiler above 1200 ℃?

- Ordinary clay brick is for burning layer, red brick for external wall, light clay brick for thermal insulation layer, built by clay refractory mortar. Sindeyuan Refractories.Hope you adopt. Thank you. In fact, there are many manufacturers producing furnace burden. We has been using products of Huaheng, which are anti-erosion, easy to construct and can improve production efficiency, reduce steelmaking cost.

- Q: How to choose construction external wall thermal insulation and fireproofing materials?

- Now external wall insulation decoration one board is more popular thermal insulation material. Low-carbon energy-saving insulation decoration board combine two constructions (decoration, insulation) into one, saving nearly ten processes,and construction period. Compared with conventional thermal insulation methods, it can increase construction efficiency one time by shortening 60% of the construction period. It integrates low carbon, energy conservation, decoration, fireproof and building aesthetic effect by combining like-dissolving-like binding system installation and bump fixed system, and under long-term cooperation of air handling system and waterproof system. It has excellent outdoor weather resistance, colour?retention, alkali?resistance, water resistance, scrubbing resistance, crack resistance and temperature change resistance, wear resistance, collion resistance and the paint film is firm and durable, with strong adhesive force and mould proof effect. It can provide all-dimensional thermal insulation, decoration, low carbon and energy conservation and fire prevention for construction projects.

- Q: What are the advantages and disadvantages of new external wall fireproof and thermal inuslation matertials?

- STP has a certain chance to self-destruct. After the sealing layer is damaged, the property will be bothered. When filling the foam glass, burst foam cement and low-strength glass fiber, the structural requirements are very high with big spraying limitations. As everyone knows that rock wool absorb organic matters, and the government do not allow us to use self-insulation, so it is not the mainstream with too low adoption rates. In fact the owners shouldn't worry about this problem. Since the developers have installed it for you, it is useless to worry about it. The other is that for those who want the original balcony closed up, if you want to shovel the original balcony wall insulation, you must pay attention to ask the construction team before you start. Because it is common that the cold bridges formed thereby will cause water seepage and moisture condensation in the balcony.

- Q: what should be paid sttention when buying the refractory?

- First, look at the appearance of the product, it will be better if the surface of product is smooth, if there are the injuries and damages which may influence the use, do not use it. Second, the main characteristics of insulation material is flame resistance, reduce the loss of fire occurred at the time of purchase combustion performance testing products, non-combustible stone wool products are the best. Third, refractory insulation with good hygroscopicity is also very important, it can keep your room drying for a long time , played the role of moisture-proof, and more capillary, the hygroscopicity is better.

- Q: Who knows what fire heat preservation material are there?

- It can be realized through inorganic insulation materials, such as glass wool, rock wool, foam glass etc.. The phenolic foam materials inside organic foam material is more special. Phenolic foam does not only have a good thermal insulation performance, but also can be combined with steel and other materials, to achieve a class A fire retardant level. Class A thermal insulation include: Rock (ore) cotton, foam glass, inorganic thermal insulation mortar, etc.. 1 thermal insulation materials with class A combustion performance Phenol, powder polystyrene particles etc.. Fire insulation materials of fire barrier zone can use class A material with class A combustion performance in rock (ore) cotton, foam glass, inorganic thermal insulation mortar. Hope my answer will help you.

Send your message to us

Raw Materials for Refractory:Calcined Bauxite (Aluminum-Containing 60%-65%) for Shaft Kiln, Rotary Kiln, and Round Kiln Applications

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords