Raw Materials for High Density Oven Insulation Board

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

Oven insulation board

1.Max Tem.:1800C

2.Density:300-700kg/m3

3.Size:Customized

High density oven insulation board

Oven insulation boardbelongs to wet vacuum suction filter molding, the loose cotton and organic

and inorganic binder.

The product has hard texture and excellent strength, anti erosion, easy processing cutting

The chemical properties of refractory fiber material stability, and light weight, good thermal

insulation effect,it is a multi-purpose product, which can be applied to the lining surface of heat resistant flame and high

temperature air directly impact.

High stability

Low thermal conductivity

Low thermal capacity

Resistance to thermal shock

Resistance to erosion

Easy to be processed and cut

High thickness precision and size precision

Exceptional ability to withstand flames and gas flows

Regular size of Oven insulation board :

LxW:600mmx400mm,1000mmx500mm,1000mmx600mm

Thickness:20-150mm

Epecial size:According to custoers' requirement

Packing:Carton or wooden box

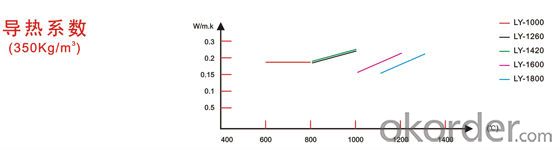

Model | LEPE-1000 | LEPE-1260 | LEPE-1400 | LEPE-1600 | LEPE-1800 | |

Classification temperature | 1000°C | 1260°C | 1400°C | 1600°C | 1800°C | |

Density(kg/m3) | 300-700 | 300-700 | 300-700 | 300-700 | 300-700 | |

Reheating Linear Change (%) | (800°CX24h)<1 | (1050°CX24h)<1 | (1200°CX24h)<1 | (1500°CX24h)<1 | (1600°CX24h)<1 | |

Chemical Composition (%) | Al2O3 | 38 | 42 | 50 | 68 | 85 |

Al2O3+SiO2 | 96 | 98 | 99 | 99.5 | 99.8 | |

Fe2O3 | 0.2 | 0.2 | 0.2 | - | - | |

Thermal conductivity of Oven insulation board

- Q: What is the best refractory company?

- Recently, many of the activities of palladium ah, find a few big beauty shoot videos, but also to send jewelry, and draw, seems to be the need to vigorously develop the market China.

- Q: How to do environmental impact assessment for refractory Co., Ltd.

- Give you a list of data, you can refer to. List of required data for environmental impact assessment 1) name, type, specification and quantity of main process equipment. 2) the supply and consumption of raw and auxiliary materials (annual consumption and unit consumption of raw materials, ingredients, electricity, new water and recycled water). 3) public utilities: power supply system: need to build several substations? What is the size of the substation? Water supply system: fresh water consumption, circulating cooling water consumption, domestic water consumption, production water consumption, fire water consumption, respectively, how much? Heating system: if the project has a self heating system, the size of heating boilers, types, scale, fuel types, sources, annual consumption, the boiler's circulating water supply.

- Q: What are the construction measures of refractory material in winter? Please descriptive briefly.

- The temperature is low in winter, so refractory bulk materials should be stirred evenly on time to avoid freezing.

- Q: What's the poured refractory material?

- According to its category, raw material of basic refractory: Mainly magnesite (magnesia), dolomite, lime, olivine, serpentine, high alumina material (sometimes neutral); main neutral raw material: chromite, graphite, silicon carbide (artificial).

- Q: What is the material of fire resistant glass reinforced plastics grating?

- What is the material of fire resistant glass reinforced plastics grating?

- Q: How to measure the influence of high-temperature performance of the products refractory in the formation of the liquid phase.

- Generally how can do high-temperature performance to measure how much liquid may affect hot bending strength rul refractoriness levels of high temperature creep?

- Q: Does anyone know about the A-level fireproof materials?

- A1-level fireproof materials include: 1. inorganic materials: glass wool, rock wool, foam glass,etc. 2. organic materials: phenolic foam insulation composite board. I hope my answer can help you.

- Q: what are the types of piping insulation material fire?rating?

- according to China's national standard GB8624-97, the combustion performance of construction materials can be divided into several grades grade A: Incombustible building material: Almost no burning material. Class B1: nonflammable building material: nonflammable material has a good flame resistance effect. when it meet the open fire in the air or burnd at high temperature, it is difficult to spread quickly, and when the fire source is removed, the combustion stop immediately. Class B2: flammable building material: flammable material has a good flame resistance effect. when it meets open fire in the air or at high temperature, it will immediately burst into flames and easily cause fire spread, such as wooden column, timber roof truss, timber beam, and wooden stairs,ect.. Class B3: inflammable building material: No flame resisting effects, highly flammable, high fire risk. 2, external wall thermal insulation materials, in accordance with fire rating, can be divided into1) grade A combustion performance thermal insulation material: Rock wool, glass wool, foam glass, foamed ceramics, foam cement, hole-closed perlite ect.. 2) class B1 combustion performance insulation materials: Extruded polystyrene board (XPS) after special treatment / Special treatment of polyurethane (PU), phenolic aldehyde, gelatine powder polyphenyl granule, etc. 3) combustion performance of class B2 insulation material: molding polystyrene board(EPS), extruded polystyrene board (XPS), polyurethane (PU), polyethylene (PE), etc.

Send your message to us

Raw Materials for High Density Oven Insulation Board

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords