QDY 5-74T Foundry Crane,Overhead Crane,Foundry Crane

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Profile

As a kind of special crane for metallurgy, the QDY foundry overhead crane is mainly used to lift molten metal(or metalloid material) and heat metal and etc. The rated lifting capacity of the QDY foundry overhead crane is less than 75T. The working class of the QDY foundry overhead crane is no more than M7.

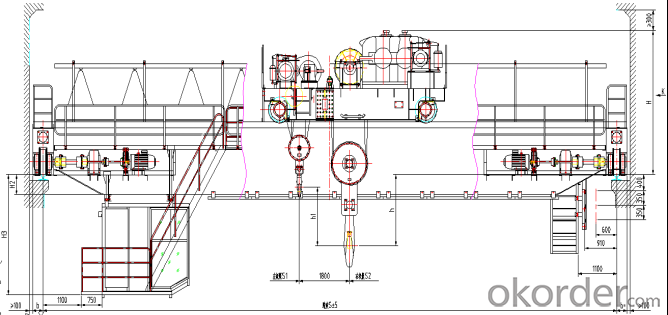

The main structural characteristic

The structural pattern of QDY foundry overhead crane adopts double girder double rail and winch with single trolley.

On the trolley of the QDY foundry overhead crane, it is equipped with main lifting mechanism and auxiliary mechanism. Each of the lifting mechanism adopts independent transmission system. Not only can the main lifting mechanism and auxiliary lifting mechanism complete the lifting separately, but also the main lifting mechanism and auxiliary can overturn the equipment cooperatively.

The working principle of the lifting mechanism: by means of acting of the lifting electric motor and changing speed by the reducer, then, the drum coupling or the C-type disk type gear will take the drive drum, the steel wire rope coiling system will complete the elevation of the hook.

The drive structural type traveling mechanism of the crane adopts 1/2 with stable braking and non-slipping phenomenon.

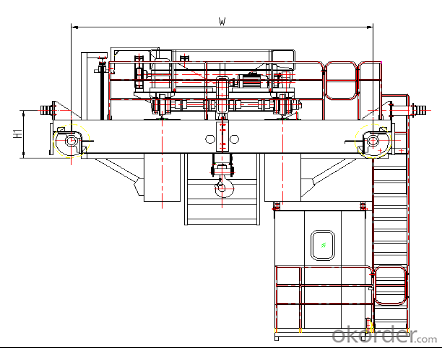

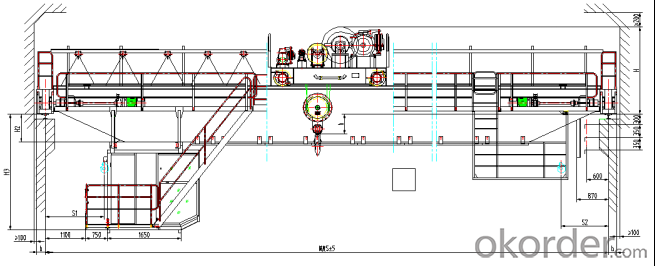

The span structure

The span structure is the main body of the crane and the main stress structure. The type of the span structure is double-girder and double-rail, which is mainly made up of main girder, end girder, walking board, handrail, ladder and other attached metal structure.

The structure of main girder is right box girder. Below the main girder, it is equipped with thermal insulation device. The cross section of the main girder adopts finite element calculation method to analysis and calculate systematically, which can ensure the cross section has enough strength, rigidity and stability of the whole overhead crane. On the walking board, it is set with crane traveling mechanism and electronic equipment reasonably, which aims to ensure the access of the operator conveniently.

The deflection upward of the crane is(0.9~1.4)S/1000. And position of the max. deflection of the is controlled in the range of 1/10S.

The structure of the end girder is box type. The connection between the main girder and end girder adopts rigid coupling. The disconnection of the end girder is connected by high strength bolt.

The attached steel structure is made up of walking board, handrail, ladder and the main steel structure.

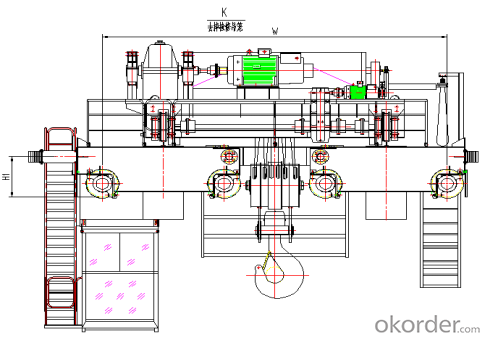

Lifting structure

The main lifting mechanism and auxiliary are set on the same trolley bracket, which is set with separately drive device. The allocating of the drive system of the main lifting mechanism and auxiliary lifting mechanism has following characteristic, such as compact structure,convenient maintenance and safety and reliability.

The lifting mechanism is made up of electric motor, brake, reducer, drum, pulley block, hook group, steel wire rope and other structure. Driving by single electric motor and lowering the speed by reducer, then it drives the duplex drum. By means of the steel wire rope coiling system that is made up of fix pulley and movable block elevates the materials.

Technical specification

Lifting capacity | t | 5 | 10 | |||||||||||||

Span | m | 13.5 | 16.5 | 19.5 | 22.5 | 25.5 | 28.5 | 31.5 | 13.5 | 16.5 | 19.5 | 22.5 | 25.5 | 28.5 | 31.5 | |

Max lifting Height | 16 | 15 | ||||||||||||||

Speed | Main | m/min | 13 | 13 | ||||||||||||

Trolley traveling | 39.5 | 35.2 | ||||||||||||||

Crane traveling | 93.7 | 95.2 | 95.2 | 88.3 | ||||||||||||

Main dimension(mm)

| W | 3800 | 3950 | 5400 | 4550 | 5500 | ||||||||||

S1 | 1500 | 1300 | ||||||||||||||

S2 | 1415 | 1650 | ||||||||||||||

H | 1881 | 2028 | 2078 | |||||||||||||

H1 | 765 | 800 | 765 | 850 | ||||||||||||

H2 | 126 | 226 | 376 | 526 | 676 | 826 | 976 | 128 | 228 | 378 | 528 | 628 | 778 | 928 | ||

H3 | 2546 | 2646 | 2796 | 2946 | 3096 | 3246 | 3396 | 2548 | 2648 | 2798 | 2948 | 3048 | 3198 | 3348 | ||

h | 150 | 604 | 554 | |||||||||||||

b | 230 | 230 | ||||||||||||||

Max wheel pressure | KN | 85 | 92 | 98 | 107 | 119 | 125 | 132 | 116 | 125 | 132 | 140 | 150 | 160 | 167 | |

Power source | 3-Phase A.C 380V 50Hz | |||||||||||||||

Trolley traveling mechanism

The trolley traveling mechanism adopts centralized driving two wheels plan. It is driven by electric motor. Then, the power is delivered to the reducer by the gear coupling and driving shaft. After it is slowed down by the reducer, the driving shaft and gear coupling will drive the driving wheel. Then it will drag the whole machine to complete the longitudinal motion. On the front end of the wheel, it is set with rail cleaner, which aims to automatically clean the stumbling block on the surface of the rail conveniently. It can ensure the safety of the crane traveling.

Crane traveling mechanism

The crane traveling mechanism adopts two electric motor to drive the driving wheel. It is driven by electric motor. Then, the power is delivered to the reducer by the gear coupling and driving shaft. After it is slowed down by the reducer, the driving shaft and gear coupling will drive the driving wheel. Then it will drag the whole machine to complete the longitudinal motion. On the front end of the wheel, it is set with rail cleaner, which aims to automatically clean the stumbling block on the surface of the rail conveniently. It can ensure the safety of the crane traveling.

Protection and indicator

The crane is set with switch for emergency power off. Under the emergency condition, it will cut off the total power source.

The electric motor is equipped with complete function protective device, which can effectively protect the over-current and short circuit. All the doors of the handrail are set with electronic interlock.

Overload limiter: the QDY foundry overhead crane is set with overload limiter. When it reaches the 90% rated load, the display will send a alarming automatically. When it reaches the 110% rated load, the QDY foundry overhead crane will cut off the the power source of the lifting mechanism.

The protective device for lifting limit position: the lifting mechanism of the hook is set with limit device. When it is lifted at the limit position, it will cut off the power source automatically.

Stroke limiter:on both sides of the crane and trolley traveling mechanism are set with stroke limiter. When the crane and trolley travel at the limit position, it can cut off the the power source automatically and it can travel reverse direction.

QDY74/20t-13.5~31.5m A7 Foundry Crane

Technical specification

Lifting capacity | t | 74/20 | |||||||||||

Span | m | 13.5 | 16.5 | 19.5 | 22.5 | 25.5 | 28.5 | 31.5 | |||||

Max.lifting height | Main hanger | 18 | |||||||||||

Auxiliary hanger | 20 | ||||||||||||

Speed | Main | m/min | 6.4 | ||||||||||

Auxiliary | 9.7 | ||||||||||||

Travelling of trolley | 32.5 | ||||||||||||

Crane traveling | 58 | ||||||||||||

Main dimension(mm)

| W | 6800 | |||||||||||

S1 | 1250 | ||||||||||||

S2 | 2800 | ||||||||||||

H | 3570 | 3572 | 3576 | 3580 | 3582 | 3582 | 3584 | ||||||

H1 | 900 | ||||||||||||

H2 | 490 | 690 | 694 | 700 | 900 | 1102 | 1104 | ||||||

H3 | 2910 | 3110 | 3114 | 3120 | 3320 | 3522 | 3524 | ||||||

h | 1730 | 1728 | 1724 | 1720 | 1718 | 1718 | 1716 | ||||||

h1 | 1420 | ||||||||||||

b | 300 | ||||||||||||

Max wheel pressure | KN | 271 | 287 | 303 | 319 | 331 | 334 | 361 | |||||

Power source | 3-Phase A.C 380V 50Hz | ||||||||||||

Send your message to us

QDY 5-74T Foundry Crane,Overhead Crane,Foundry Crane

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords