PWF/R Spoke Rotor Type Powder Qualitative Feeding System

- Supplier:

Hefei GoodTimes Automation Co.,Ltd.

Hefei GoodTimes Automation Co.,Ltd.

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1000000 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction

PWF/R Series Spoke Rotor Powder Quantative Feeding System is mainly used for constant feed and control of kiln feed raw meal in cement production, and constant feeding and metering of powdery materials such as fly ash and slag powder with advanced technology, accurate metering, stable operation and convenient maintenance.

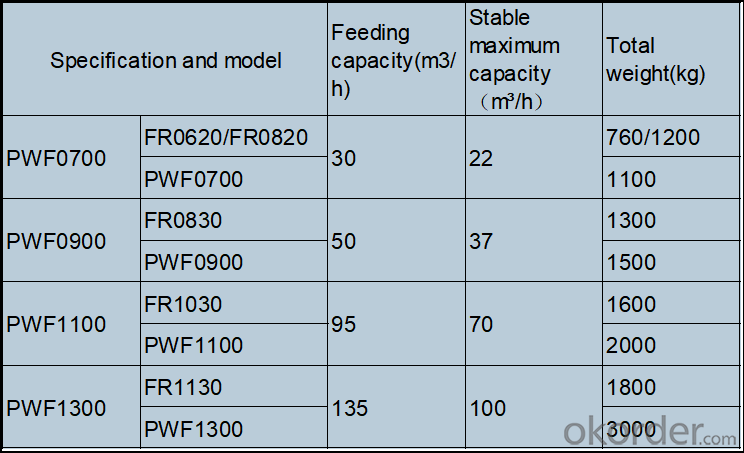

Technical indexes

Applicable material: material with size less than 2mm, such as slag powder, fly ash ,carbide slag powder and cement powder.

Moisture: <5%

Feeding capacity: 3.0≤180m3/h

Metering accuracy: ≤ ±0.5%

Adjusting range: ≤±1.0%

Adjusting range: 1:10

Characteristics

1. It directly measures material weight inside the rotor, whose metering accuracy is accurate and will not be influenced by material property, air flow and material flow properties.

2. Its bearing sealing prejudging technology and rotor suspended construction can ensure a long service life; within 5 years, there will be hardly any wearing parts.

3. It's of heavy duty adjustable suspension structure, with high weighing sensitivity whose real-time regulation is possible.

4. It adopts the predictive control technology, which saves in the control system the rotor load and its angular displacement at any time. Before the material is discharged, the angular speed during material discharging is calculated on the basis of the system set flow rate and rotor load. In controlling the speed of frequency variable motor, we can realize the quantitative feeding. The technology is advanced, with stable feeding.

5. It's of simple structure and full-sealing design. Inside, there's only a low speed rotor running, with easy operation, reliable running and no leaking.

6. It adopts spoke rotor, and the material freely falls during system running. During the rotor rotation, the material fluctuation and filling rate variation are small; the material feeding is uniform and stable.

7. According to the special process and the material properties, we adopt different pre-feeding device and implement pre-feeding+ predictive control technology (double loop control), ensuring continuous and stable feeding with high metering accuracy.

8. With special design of long service life, the system has a long service life, a low default rate and easy maintenance.

Utilization

Mainly suitable for constant coal feeding of industrial kilns in building materials, metallurgy, power, nonferrous metal and chemical industries, also for constant coal feeding of other powdery fuels such as petroleum coke powder.

1. Constant coal feeding of the rotary kiln and calciner for cement production in the building material industry.

2. Constant coal feeding of rotary kilns for aluminum oxide, magnesium oxide and zinc oxide burning in the non-ferrous metallurgy industry.

3. Constant coal feeding of rotary kilns for pellet, lean iron ore magnetization burning and ferronickle smelting in the ferrous metallurgy industry.

4. Constant coal feeding of rotary kilns for soda, phosphate fertilizer and barium sulfide burning in the chemical industry.

5. Constant coal feeding of waste heat power generation boilers.

6. Constant coal feeding of raw material burning rotary kiln for refractory material production.

7. Constant coal feeding of lime, carbon and fine ceramsity kilns in other industries.

Company Introduction

Hefei GoodTimes Automation Co., Ltd. is a technique oriented state-level high-tech enterprise, transformed from Hefei Jinshan Science and Technology Industrial Company organized on the basis of automation institute of Hefei Cement Research & Design Institute Corporation Ltd. under of CNBM.It was awarded the Anhui Industrial Design Center, Hefei Enterprise Technology Center, Hefei Brand demonstration Enterprise, Hefei Engineering Technology Research Center. The core team is composed of the automation laboratory of construction institute. It is a scientifific and technological enterprise with a long history and strong technical strength, which integrates scientifific research and development, equipment manufacturing, engineering settings, and technical service.The company has established a perfect quality assurance system, which has passed the authentication of ISO9001 quality management system certifification,ISO14001environment management system certifification,OHSAS18001 occupational health & safety management system certifification, level 3 work safety standardization and Certifificate for China Compulsory product certifification.It is engaged and specialized in the development of the whole series of material measurement, process control, factory power distribution and electric control, monitoring and control devices for cement production as well as their manufacturing and services. The company has inherited innovative development experience from the core team for more than 60 years. It is staffed with a professional team with fifirm grasp of the latest technology and rich practical experience. In product development, production and services, it adheres to the business concept of “Customer-centered, innovation-driven, aiming at the win-win”. The company will continue to make customers feel “carefree, assured and content"

Send your message to us

PWF/R Spoke Rotor Type Powder Qualitative Feeding System

- Supplier:

Hefei GoodTimes Automation Co.,Ltd.

Hefei GoodTimes Automation Co.,Ltd.

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1000000 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches