Baseball Packaging Tape with PVC Electrical Tape Embossed Printing

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 roll

- Supply Capability:

- 100000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of PVC Electrical Tape with Embossed Printing

A thin premium grade plasticized PVC film coated with an aggressive rubber based adhesive with good characteristics. It is highly conformable and unaffected by most chemicals and moisture

Application of PVC Electrical Tape with Embossed Printing

Electric insulation below 600V; Insulating wrapping of electric wires and cables; Marking of electric wires and cables; Can be used indoors and out door

Available Size of PVC Electrical Tape with Embossed Printing

Paper Core ID: 76mm; 56mm; 38mm; 32mm

Jumbo Roll size: 1250mm x 33m

Cut roll size: 19mm x 10m; 19mm x 20m or as per customer's requirement

Cut rolls: Nine rolls in one plastic bag, placed in cartons, with or without pallet

Packing of PVC Electrical Tape with Embossed Printing

Jumbo rolls & log rolls: Packed with kraft paper and stretch wrap film, with or without pallet

Cut rolls: Shrink package, placed in cartons, with or without pallet

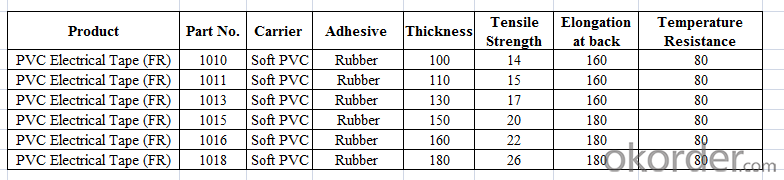

Technical Data of PVC Electrical Tape with Embossed Printing

Product Show of PVC Electrical Tape with Embossed Printing

FAQ: What are your company advantages?

Company Advantages:

1. Stable financial status and sound reputation as a state invested corporation under the direct administration of the State Council of PRC;

2. CNBM’s worldwide influence as one of the 500 global fortunes specializing in building materials including adhesive tapes;

3. More than a decade’s exporting experience and technology in adhesive tape industry;

4. Preferential shipping channels, with a separate team dealing with shipping.

- Q: Is packaging tape safe to use on plastic shower curtains?

- Yes, packaging tape is safe to use on plastic shower curtains. It provides a secure and reliable way to attach or mend the curtains without causing any damage.

- Q: Can packaging tape be used for sealing fabric or textiles?

- No, packaging tape is not suitable for sealing fabric or textiles as it may not adhere properly and could damage the material. It is recommended to use fabric-specific or textile adhesive tapes for this purpose.

- Q: Does packaging tape come in different finishes or textures for aesthetic purposes?

- Yes, packaging tape does come in different finishes or textures for aesthetic purposes. Some examples include glossy, matte, clear, colored, patterned, and even customizable options. These variations allow individuals and businesses to choose packaging tape that aligns with their branding or personal preferences.

- Q: Sealing tape sales skills and knowledge, please explain to professionals! Help, please

- Sales strategy.What do you sell in the sales process?Answer: myself1, the world's first car sales Jo Gilad said: "I do not sell my Chevrolet car, I sell myself."";

- Q: Can packaging tape be used on different materials?

- Yes, packaging tape can generally be used on different materials. It is commonly used to seal cardboard boxes, but it can also adhere to materials such as plastic, metal, and wood. The adhesive on packaging tape is designed to provide strong adhesion on a variety of surfaces, making it versatile for different packaging needs.

- Q: How do you store unused rolls of packaging tape?

- To store unused rolls of packaging tape, it is important to keep them in a cool and dry place to maintain their adhesive properties. One option is to use a plastic storage bin or container with a lid, which will protect the tape from moisture and dust. Alternatively, you can use a dedicated tape dispenser or a tape gun that has a built-in storage compartment for additional rolls. This not only keeps the tape organized but also prevents it from unraveling and becoming tangled. Remember to keep the rolls upright to avoid any potential damage or deformation. By properly storing unused rolls of packaging tape, you can ensure they remain in good condition and ready for use when needed.

- Q: Can packaging tape be used for sealing packages with perishable food items?

- Using packaging tape to seal packages containing perishable food items is not advisable. Perishable food items necessitate appropriate packaging materials that can establish seals resistant to air and moisture, thereby preserving their freshness and preventing contamination. Packaging tape is not specifically designed for this purpose and may not be capable of offering the required level of protection. It is highly recommended to employ specialized food-grade packaging materials such as plastic wrap, vacuum-sealed bags, or resealable containers to guarantee the safety and quality of perishable food items during transportation.

- Q: Can packaging tape be used for sealing glass jars?

- Indeed, sealing glass jars is possible with packaging tape. However, it should be noted that packaging tape is not specifically designed for this purpose and more suitable alternatives are available. While packaging tape can offer a temporary seal, it may not be as effective in preserving the freshness and airtightness of the jar's contents. Furthermore, the tape may not adhere well to glass surfaces and could peel off over time, potentially compromising the seal. For optimal results in preserving the contents of glass jars, it is recommended to utilize specialized methods and materials such as rubber gaskets, metal lids with screw caps, or heat-sealing techniques.

- Q: What is packaging tape?

- Packaging tape is a type of adhesive tape specifically designed for sealing and securing packages. It is typically made of a strong and durable material, such as polypropylene or PVC, and is used to hold boxes and cartons together during transportation or storage.

- Q: Is the insulating tape waterproof?

- Similar to plastic, it's waterproof. But it's insulated, too

Send your message to us

Baseball Packaging Tape with PVC Electrical Tape Embossed Printing

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 roll

- Supply Capability:

- 100000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches