PVC Coated or Hot Dipped Galvanized Welded Wire Mesh( ISO9001 Manufacturer)

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 roll

- Supply Capability:

- 3000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

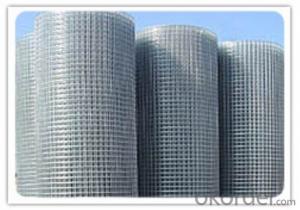

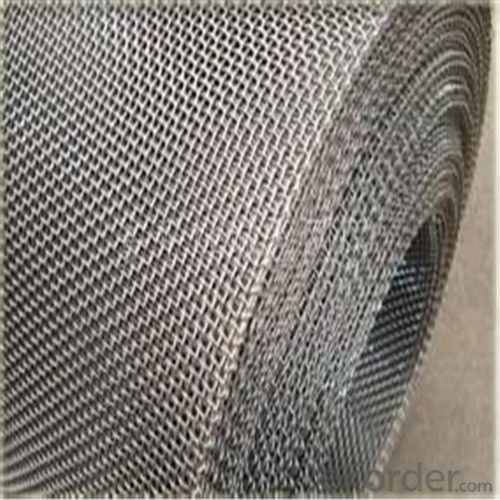

1.Structure of Welded Wire Mesh Description:

Welded Wire Mesh is make of Quality low carbon steel wire, stainless steel wire, aluminum alloy wire.Chain link fence with uniform mesh hole, flat surface, beautiful apprearance, great corrosion resistance, long service life. Does not dag or roll up at the bottom.

Welded Wire Mesh is mainly used in feeding chickens, ducks, geese, rabbits, zoo fence, machinery and equipment protection, highway guardrail, sports fence, the road green belt protection, storage, security and reinforcement materials, fencing of sports field, parks, zoos, ocean fishing, also security and protection of construction sites, rivers, mountain slope soil fixing and residential security.

2.Main Features of Welded Wire Mesh :

,• Uniform opening

• Beautiful shape

• Simple weaving

• Good anti-corrosion

• Practical use

• Firm structure

3. Welded Wire Mesh Images

4. Chain link Wire Mesh Specification

| Specification List of Welding Wire Mesh | ||

| Opening | Wire Diameter | |

| In inch | In metric unit(mm) | |

| 1/4" x 1/4" | 6.4mm x 6.4mm | 22,23,24 |

| 3/8" x 3/8" | 10.6mm x 10.6mm | 19,20,21,22 |

| 1/2" x 1/2" | 12.7mm x 12.7mm | 16,17,18,19,20,21,22,23 |

| 5/8" x 5/8" | 16mm x 16mm | 18,19,20,21, |

| 3/4" x 3/4" | 19.1mm x 19.1mm | 16,17,18,19,20,21 |

| 1" x 1/2" | 25.4mm x 12.7mm | 16,17,18,19,20,21 |

| 1-1/2" x 1-1/2" | 38mm x 38mm | 14,15,16,17,18,19 |

| 1" x 2" | 25.4mm x 50.8mm | 14,15,16 |

| 2" x 2" | 50.8mm x 50.8mm | 12,13,14,15,16 |

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your welded link Wire Mesh?

As a profession supplier ,we are engaged in the production and trade of wire mesh, like welded link Wire Mesh, hot rolled steel plate/coil, cold rolled steel coil, gi steel coil, pp gi coil, corrugated sheet, wire rod and so on.

We have established business relationships with clients in the Southeast Asia, South Asia, North America, and many other countries and regions. Our goal is to provide all our customers with qualified and low-cost steel products.

②The reason why you choose us?

· Diversification of products

. Professional sales team

· Industry experience over 15 years

· Shipment of goods -More than 50 countries worldwide

· We have the most convenient transport and prompt delivery

· We offer competitive price with best service

· We have win high reputation based on best quality products

③How long can we receive the product after purchase?

In the purchase of welded link Wire Meshwithin three working days, we will arrange the factory delivery as soon as possible. The pacific time of receiving is related to the state and position of customers. Commonly 15 to 20 working days can be served.

- Q: What is the effect of the wire mesh on the floor

- strong ground local load-bearing capacity: in the processing workshop, garage and other ground load larger room, to warm with wire mesh can improve the overall strength of the ground layer, to avoid ground cracking, collapse and so on.

- Q: How the wire is welded

- Will not affect the strength of the wire. It is not easy to break due to excessive heat input. Fusion welding can not do this.

- Q: Barbed wire mesh 20 mesh and 30 mesh what is the difference

- The mesh count refers to the number of holes of 2.54 cm. The unit used to express the mesh in the mesh product specification is hole / cm or line / cm. In countries and regions using imperial units of measurement, the mesh size is expressed in holes / inch or lines / inch.

- Q: Wire mesh for wire mesh applications

- Body network, can also be used for solid material classification screening, liquid and mud filtration. Weaving and features: the first rolling after the series, two-way wave bending, locking bending, flat top bending, two-way bending, one-way wave bending, solid structure.

- Q: Construction in the wall and the beam at the junction of nail wire mesh what role

- Fixed pipe: the appearance of the insulation layer laying wire mesh with nylon tie to fix the pipe, characterized by fast construction, accurate positioning, the role of all the pipe device is good.

- Q: How does proe draw wire mesh?

- The main is the rest assured that the grid generation, first in accordance with the form of a grid to draw a curve, of course,

- Q: What is the barbed wire fence? What is the general specification?

- With a variety of different columns to connect. Constitute a nice, high protective performance of the barbed wire fence.

- Q: Is the warm tube laid on top of the steel wire or below?

- on the maintenance of the warm tube I told you to see what you use the pipe to decide, if the use of high temperature polyethylene PE-RT material, then you can use a dedicated interface to hot-melt connection to repair, if used Is the coach polyethylene PE-X pipe, then it is difficult to deal with,

- Q: How is the wire mesh made

- First of all, the application of electrolytic pickling, high pressure flushing, card electric drying of the new technology successfully tested the continuous production of the wire drawing, the drawing process from the intermittent production into a continuous production, weakened the labor intensity and reduce the metal consumption.

- Q: Why do you want to shop a barbed wire?

- In the laying of this layer of wire mesh, we must pay attention to the wire mesh and the wall of the banding point is certainly not the density does not meet, or else the wall will produce a hollow problem. Also, we must pay attention to the proportion of cement mortar ratio, the proportion will not increase the probability of cracks in the wall.

Send your message to us

PVC Coated or Hot Dipped Galvanized Welded Wire Mesh( ISO9001 Manufacturer)

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 roll

- Supply Capability:

- 3000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords