Solar Vacuum Tube PV Modules Made in China for Overseas Market

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pallet

- Supply Capability:

- 100000000 pallet/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

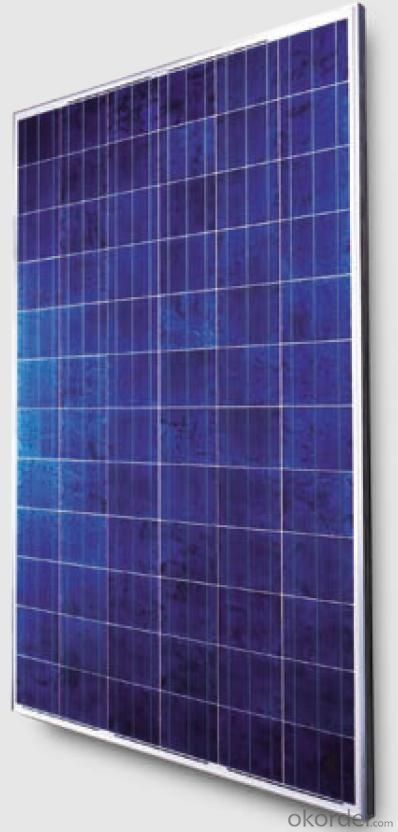

Solar panel refers either to a photovoltaic (PV) module, a solar hot water panel, or to a set of solar photovoltaic modules electrically connected and mounted on a supporting structure. A PV module is a packaged, connected assembly of solar cells. Solar panels can be used as a component of a larger photovoltaic system to generate and supply electricity in commercial and residential applications. Each module is rated by its DC output power under standard test conditions, and typically ranges from 100 to 320 watts. The efficiency of a module determines the area of a module given the same rated output – an 8% efficient 230 watt module will have twice the area of a 16% efficient 230 watt module. There are a few solar panels available that are exceeding 19% efficiency. A single solar module can produce only a limited amount of power; most installations contain multiple modules. A photovoltaic system typically includes a panel or an array of solar modules, an inverter, and sometimes a battery and/or solar tracker and interconnection wiring.

Solar modules use light energy (photons) from the sun to generate electricity through the photovoltaic effect. The majority of modules use wafer-based crystalline silicon cells or thin-film cells based on cadmium telluride or silicon. The structural (load carrying) member of a module can either be the top layer or the back layer. Cells must also be protected from mechanical damage and moisture. Most solar modules are rigid, but semi-flexible ones are available, based on thin-film cells.

Electrical connections are made in series to achieve a desired output voltage and/or in parallel to provide a desired current capability. The conducting wires that take the current off the modules may contain silver, copper or other non-magnetic conductive transition metals. The cells must be connected electrically to one another and to the rest of the system. Externally, popular terrestrial usage photovoltaic modules use MC3 (older) or MC4 connectors to facilitate easy weatherproof connections to the rest of the system.

Bypass diodes may be incorporated or used externally, in case of partial module shading, to maximize the output of module sections still illuminated.

Some recent solar module designs include concentrators in which light is focused by lenses or mirrors onto an array of smaller cells. This enables the use of cells with a high cost per unit area (such as gallium arsenide) in a cost-effective way.

Specifications:

solar panels from 5W--300W, made of TAIWAN MOTECH brand cells,with CO in TAIWAN,Mono and Poly with VDE,IEC,CSA,UL,CE,ISO.

We import solar cells from Taiwan Motech brand, with this CO in taiwan and our CSA certification,we can still sell goods to Anti-dumping areas like USA. Our main products are solar panels, off grid and on grid solar home systems , solar street lighting systems, solar water heating system,solar pump,solar attic fan, solar DC LED lights and solar DC refrigerators.

Certificates : ISO, CE, VDE IEC, MCS, CSA-UL, CEC.

Delivery time: sample 10days, order 25-30days.

Sample: charged.

Payment term: T/T 30% as deposit, 70% before shipment. Or irrevocable L/C at sight.

Trade term: FOB Shenzhen or CIF destination seaport or Airport.

Characteristics:

I.Solar Cell : High efficiency crystalline solar cell. Even if under the weak light, the solar module can produce maximum power output.

II.Tempered glass (toughened glass): Anti-reflecting coating and high transmission rate glass increase the power output and mechanical strength of solar module.

III.EVA and TPT: Using high quality EVA and TPT to prevent destroying and water.

IV.AI frame: Without screw, corner connection. 6 holes on the frame can be installed easily.

V.Junction box: Multi function junction box with water proof.

VI.Long lifetime: ≥25 years; Less power decrease.

VII.Good performance of preventing from atrocious weather such as wind and hails.

VIII.Resisting moisture and etching effectively, not effected by geology.

IX.The certificate issued by international authority: UL, TUV, IEC, VDE, CE.

Quality and Safety

1. Rigorous quality control meets the highest international standards.

2. High-transmissivity low-iron tempered glass, strong aluminium frame.

3. Using UV-resistant silicon.

4. IS09001/14001/CE/TUV/UL

Warranties

1. 10 years limited product warranty

2. 15 years at 90% of the minimal rated power output

3. 25 years at 80% of the minimal rated power output

Technical date :

ITEM NO.: | Poly 156*156 cell ,60pcs . Power range from 230Wp-260Wp | ||||||

Maximum Power(W) | 230 | 235 | 240 | 245 | 250 | 255 | 260 |

Optimum Power Voltage(Vmp) | 29.4 | 29.5 | 29.7 | 30.1 | 30.3 | 30.5 | 30.7 |

Optimum Operatige Current(Imp) | 7.83 | 7.97 | 8.08 | 8.14 | 8.25 | 8.37 | 8.48 |

Open Circuit Voltage(Voc) | 36.7 | 36.8 | 36.9 | 37.1 | 37.3 | 37.5 | 37.7 |

Short Circuit Current(Isc) | 8.52 | 8.59 | 8.62 | 8.65 | 8.69 | 8.73 | 8.78 |

Solar Cell: | 156*156 Poly | ||||||

Number of Cell(pcs) | 6*10 | ||||||

Name of Solar Cells | Polycrystalline Cell | ||||||

Size of Module(mm) | 1650*992*40/45/50 | ||||||

Cable & Connector Type | Pass the TUV Certificate | ||||||

Frame(Material Corners,etc.) | Aluminium-alloy | ||||||

Back sheet | TPT | ||||||

Weight Per Piece(KG) | 19.5KG | ||||||

FF (%) | 70-76% | ||||||

Junction Box Type | Pass the TUV Certificate | ||||||

Tolerance Wattage(e.g.+/-5%) | ±3%, or 0-3% | ||||||

Front Glass Thickness(mm) | 3.2 | ||||||

Temperature Coefficients of Isc(%) | +0.04 | ||||||

Temperature Coefficients of Voc(%) | -0.38 | ||||||

Temperature Coefficients of Pm(%) | -0.47 | ||||||

Temperature Coefficients of Im(%) | +0.04 | ||||||

Temperature Coefficients of Vm(%) | -0.38 | ||||||

Temperature Range | -40°C to +85°C | ||||||

Surface Maximum Load Capacity | 5400Pa | ||||||

Allowable Hail Load | 23m/s ,7.53g | ||||||

Bypass Diode Rating(A) | 12 | ||||||

Warranty | 90% of 10 years, 80% of 25 years. | ||||||

Standard Test Conditions | AM1.5 1000W/ 25 +/-2°C | ||||||

Packing | carton or pallet | ||||||

1*20' | 14 Pallets / 316pcs | ||||||

1*40'STD | 25 Pallets / 700pcs | ||||||

FAQ:

I..Will you focus on the safety of the goods during transportation?

Yes, Safety of the cargo is the primary element that we would consider on transportation.

II..How would guarantee the quality will meet the requirements of your clients?

Before shipment, we will have inspection for each batch of goods.

III..What certificates do you have?

IEC,UL,TUV,CSA,etc.

IV..Can you do OEM according to clients’ requirements?

Yes, we have our own brand while we can provide OEM service.

- Q: Do solar vacuum tubes require a specific insulation material?

- Yes, solar vacuum tubes require a specific insulation material known as a heat pipe. The heat pipe acts as a barrier to prevent heat loss, allowing the solar vacuum tubes to efficiently capture and retain solar energy.

- Q: How do solar vacuum tubes compare to solar-powered desalination?

- Solar vacuum tubes and solar-powered desalination are both innovative technologies that harness solar energy for different purposes. Solar vacuum tubes are primarily used to generate heat for domestic or industrial purposes, such as water heating or space heating. On the other hand, solar-powered desalination utilizes solar energy to remove salt and impurities from seawater or brackish water, making it suitable for drinking or irrigation purposes. The main difference lies in their applications, with solar vacuum tubes focusing on heat generation and solar-powered desalination addressing water scarcity issues.

- Q: Is to keep the water tank with a clean, the water inside the vacuum tube is full, with no use, I say it right

- That's true。 If you really want to use, you can slightly on some water, cold water mass, hot water light, you can put the tube hot water out of the. Be careful not to put too much water, otherwise the water will be cool.

- Q: Are solar vacuum tubes suitable for use in spas and wellness centers?

- Yes, solar vacuum tubes are suitable for use in spas and wellness centers. They are an effective and environmentally-friendly option for heating water in these facilities. Solar vacuum tubes have high thermal efficiency and can provide ample hot water supply for various spa and wellness treatments. Additionally, their compact design allows for easy installation and integration into existing spa systems.

- Q: What is the lifespan of the heat pipes inside the solar vacuum tubes?

- The lifespan of heat pipes inside solar vacuum tubes can vary depending on various factors such as the quality of the materials used, maintenance practices, and environmental conditions. However, on average, heat pipes in solar vacuum tubes can last anywhere from 10 to 20 years.

- Q: The solar vacuum tube has a good heating effect

- Try something else, such as rice. Due to the excellent water absorption capacity and the family must be able to communicate with the mobile phone in a sealed bag, and then wait for a few days. Do not use a hair dryer or a stove to bake, because the external heat will damage the phone's internal precision electronic components. The correct approach is to use a clean towel quickly wipe, to ensure that the water will not flow into the charging port, headphone jack, etc..

- Q: Solar vacuum tube what color is good

- This type of consumer discrimination method of vacuum tube:1, the naked eye, the general tube and the appearance of the three high tube is dark blue, purple tube appearance is dark red2, in the sun from the tube to see, ordinary tube partial blue, three high tube partial red, purple tube is very red (pictured above)

- Q: Do solar vacuum tubes require water treatment or filtration?

- No, solar vacuum tubes do not require water treatment or filtration.

- Q: Are solar vacuum tubes suitable for areas with limited access to fuel sources?

- Yes, solar vacuum tubes are suitable for areas with limited access to fuel sources. Solar vacuum tubes rely solely on sunlight to generate heat, making them an ideal choice for locations where fuel sources such as gas or electricity are scarce or expensive. They can provide a reliable and sustainable source of hot water or space heating without the need for traditional fuel sources, helping to reduce dependency on non-renewable energy and lower overall energy costs in such areas.

- Q: How do solar vacuum tubes perform in areas with high levels of air particulates?

- Solar vacuum tubes can experience reduced performance in areas with high levels of air particulates. These particulates, such as dust or pollution, can accumulate on the surface of the tubes, blocking sunlight and decreasing their efficiency. Regular cleaning and maintenance of the tubes can help mitigate this issue and ensure optimal performance.

Send your message to us

Solar Vacuum Tube PV Modules Made in China for Overseas Market

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pallet

- Supply Capability:

- 100000000 pallet/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords