Punching Hole Meshes -- Best Choice for You

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 3000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

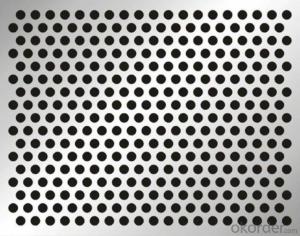

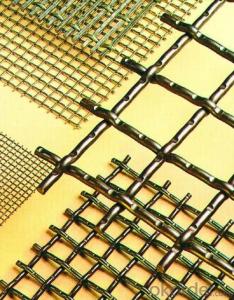

1.Structure of Punching Hole Meshes Description

Punching hole mesh with various patterns mainly standard perforated patterns and decorative patterns. Custom designs available.

Precise parameters guaranteed.

Hole Patterns including: Round; Rectangular hole; Square; Triangle; Diamond; Hexagonal; Cross; Slotted; and other patterns according to your drawings or application requirement.

2.Main Features of the Punching Hole Meshes

•Made of high quality steel wire.

•Various configurations and sizes

•Used for loose strata to aviod falling rocks.

•Suitable for shotcrete applications.

•Range of sizes to suit roadway width and bolting patterns.

•Easy installation,

•Avaliable in black or hot dip galvanized.

3. Punching Hole Meshes Images

4. Punching Hole Meshes Specification

Mesh/Inch | Wire Diameter | Aperture | Open Area | Weight(LB) /100 Square Foot | ||

Inch | MM | Inch | MM | |||

1x1 | 0.080 | 2.03 | 0.920 | 23.37 | 84.6 | 41.1 |

2X2 | 0.063 | 1.60 | 0.437 | 11.10 | 76.4 | 51.2 |

3X3 | 0.054 | 1.37 | 0.279 | 7.09 | 70.1 | 56.7 |

4X4 | 0.063 | 1.60 | 0.187 | 4.75 | 56.0 | 104.8 |

5X5 | 0.041 | 1.04 | 0.159 | 4.04 | 63.2 | 54.9 |

10X10 | 0.025 | 0.64 | 0.075 | 1.91 | 56.3 | 41.2 |

24X24 | 0.014 | 0.356 | 0.0277 | 0.70 | 44.2 | 31.8 |

80X80 | 0.0055 | 0.140 | 0.0070 | 0.18 | 31.4 | 16.9 |

90X90 | 0.005 | 0.127 | 0.0061 | 0.16 | 30.1 | 15.8 |

100X100 | 0.0035 | 0.089 | 0.0065 | 0.17 | 42.3 | 8.3 |

120X120 | 0.0037 | 0.0940 | 0.0064 | 0.1168 | 30.7 | 11.6 |

160X160 | 0.0025 | 0.0635 | 0.0038 | 0.0965 | 36.4 | 5.94 |

200X200 | 0.0021 | 0.0533 | 0.0029 | 0.0737 | 33.6 | 6.2 |

250X250 | 0.0016 | 0.0406 | 0.0024 | 0.0610 | 36.0 | 4.4 |

300X300 | 0.0051 | 0.0381 | 0.0018 | 0.0457 | 29.7 | 3.04 |

325X325 | 0.0014 | 0.0356 | 0.0017 | 0.0432 | 30.0 | 4.40 |

400X400 | 0.0010 | 0.0254 | 0.0015 | 0.370 | 36.0 | 3.3 |

500X500 | 0.0010 | 0.0254 | 0.0010 | 0.0254 | 25.0 | 3.8 |

635X635 | 0.0008 | 0.0203 | 0.0008 | 0.0203 | 25.0 | 2.63 |

5.FAQ of Punching Hole Meshes

①The general use?

Welded Wire Mesh with excellent corrosion resistance and oxidation resistance, is extensively used as fencing, decoration and machinery protection material in agriculture, construction, transport, mine, sports field, lawn and various industrial fields

② Our Advantages?

1. Low cost for molding or tooling

2. Advanced & Standardization workshops and facilitates.

3. High-tech and high precision manufacturing equipment.

4. Strict ISO14001:2004 , ISO9001:2008 standards.

5. ROHS compliant & enviroment friendly products.

6. Professional technical specialists and management personel

7. 100% in house inspection before delivery

③Why you choose us?

We can make high precision parts from foil as thin as 0.025mm.

Main metal material we can photo etching including:

Stainless steel, iron, brass, copper, Kovar, Molybdenum

Surface can be paint color, gold/silver plated or mirror finish

Products can be made according to your drawing in .dxf or .dwg format.

Please feel free to contact us for the quotation

- Q: On the issue of their own screen printing

- To India, you need to buy something: screen version, ink [water], scraper, so much can work

- Q: What is the process of the screen printing process?

- low image quality: screen printing speed is slow, not suitable for online production; ⑥ low image accuracy: screen printing resolution is not high, the conventional number of lines 24

- Q: How to get the correct fishing wire

- close the net, with a large bowl in accordance with the way when the net wire to close the net, with the float side of the received good, there are fish directly to the basin.

- Q: Screen printing and other printing methods of the difference

- Printed high weatherability, fastness. Simple operation procedure, simple tool / machine, relatively low investment, high return rate.

- Q: The difference between screen printing characteristics

- All shapes of things can be printed with silk screen. For those special diamonds can also be screen printing.

- Q: Screen printing and screen printing plate on the photosensitive material What are the requirements

- Synthetic fiber or metal frame pattern using hand-painted film or photochemical plate making silk screen version of the modern silk printing technology is the use of optical materials through the system plate production

- Q: How to clean the screen plate

- The screen is automatically cleaned, rinsed and dried, and the screen is automatically stopped when the set time is reached. The door is opened and the drying time is adjusted by pressing the start switch.

- Q: How to make screen printing layout smooth

- Paint the (pattern) paint, repeat it several times and check that the pattern is transparent. If the number of prints is not large, the back generally do not need to paint.

- Q: What is the screen printing plate?

- Is a certain tension by the tension of the screen after the tension on a frame, and then coated with a photoresist on the top and then with a specific pattern of film with UV light after the light washed out of the pattern made of water.

- Q: What is the principle of screen printing?

- Type of printing: no printing - such as inkjet, electrostatic copying, laser. Printed - such as movable type, off, screen.

Send your message to us

Punching Hole Meshes -- Best Choice for You

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 3000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords