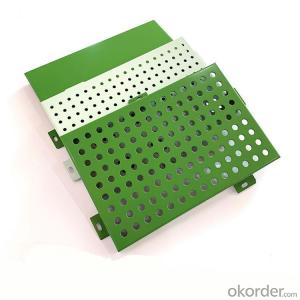

Punched / Perforated Aluminum Panel for Aluminum Wall Facade

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 60000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Punched / Perforated Aluminum Panel for Aluminum Wall Facade

Product Description

Quality Management Standards: ISO 14001, ISO 9001: 2000, SGS, CE, ASTM.

Product Name: PVDF aluminium composite panel, PE aluminium composite panel,HDP Aluminium composite panel, Polyester Aluminium composite panel, brushed aluminium composite panel, hairline aluminium composite panel, mirror aluminium composite panel, pearl color aluminium composite panel, Kynar 500 aluminium composite panel, nano aluminium composite panel, pvdf acm, pe acm, polyester acm, kynar 500 acm, mirror acm, brush acp, brushed acm, aluminium composite material, aluminium composite

Basic Information & Specifications:

Brand Bolliya, Boreer & OEM

Item No. PF-811 Flash Silver

Coating Coating Type PVDF, FlurocarbOn Powder >70% (Kynar 500)

Coating Thickness >25 microns

Specification Aluminum Skin Alloy 1100 H18, 3003 H24, 3105 H14

Thickness 0.2, 0.3, 0.4, 0.5mm

Core Thermal PE core

FR mineral Filled Core (B1 class)

Width 1220, 1250, 1500mm

Special width availabel upon request

Length 2440, 4880mm, any up to 5800mm

Total Thickness 3, 4, 6, others from 1mm to 10mm all avaliable

Standard Size 1220X2440X3mm

1250X2440X4mm

Characteristics

Smooth surface coating

Excellent impact resistance

Outstanding weather & UV resistance

Light weighted

Cost efficient

Good heat & sound insulation

Easy to process, install and maintain

Fabulous dimensional stability

Splendid corrosion resistance

Diversified colors

Recyclable

Applications:

Facade cladding, curtain wall cladding, interior wall decoration,

Renewal of old building facade, signboard, furnitures, truck box, etc.

Technical Datas:

Painting: Kynar 500 PVDF resin with quality dying material only from PPG or Beckers.

2-3 coating system as one of PPG's authorized coater in China

Color remain bright and vivid after long time duration even under server weathering considtion.

Why Kynar 500 PVDF coating? The one and only resin human could find can survive server neveda desert environment. PPG is the oldest PVDF resion supplier in the world, and they are famous for colorful and durability of dying materials. Choosing Bolliya aluminum composite panel means the everlasting of your building

Color: More than 30 standard colors and customerized colors available. Strict ΔE control.

ΔE means the color coherence control in same or different batch, eash the pressue on client's stocking plan or supplying line.

Core: PE flexible core or FR core

FAQ:

Q: Can you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 5 tons

Q: What are your payment terms?

A: We accept L/C, D/A, D/P, T/T, West Union, etc

- Q: What should I pay attention to? What brand of aluminum plastic plate is good? Aluminum-plastic plate those manufacturers, please list, thank you!

- , Folding aluminum-plastic plate corner, easy to break is not PE material or doping to make false.

- Q: Will the aluminum plate and aluminum plate and plastic plate what is the difference ah?

- Aluminum plate with aluminum buckle plate is the best one is a long one is a plastic one is the price of aluminum alloy is not necessarily see where the aluminum plate in OKorder, there are more than 100 are also dozens of fast also Buckle on the thousands of aluminum plate also if the above lights bad bad repair Kouban better, then he can be a piece of demolition

- Q: OKorder 3M glass curtain wall adhesive tape and aluminum-plastic plate Lvkou Ban and aluminum veneer special double-sided tape where there?

- US 3M company in OKorder designated agent 3M tape and glue labels and other products distribution and double-sided tape cutting and precision cross-forming! My company's tape has a professional curtain wall with double-sided adhesive.

- Q: Home decoration, aluminum-plastic board in general how thick ah?

- Listen to me, three millimeters thick on the line, the market has to sell single-sided aluminum-plastic plate, the kind of do not use, generally can not hold a year or two, are the pit of the public, and where you are decorated , The general aluminum-plastic plate should be slotted, the foil is too thin and bad, easy to break, that is, there will be a bump will leave indentation, it is beautiful, if the package is the best choice for aluminum foil, that is, wink Of the thick layer of aluminum, more than 12s, can be more flat, try to choose aluminum-plastic plate ruthless, the plastic is not followed with the cut off, the price of the standard board in a 130 or so, go to the market to see it Questions can be asked again

- Q: Sub-white aluminum-plastic door with a white aluminum side, how? The effect is good?

- The easiest way is to directly on the white aluminum-plastic plate directly attached to a layer of black aluminum plate. Since you have done aluminum-plastic board layer, that grass-roots flatness should not be a problem! We often do shop strokes, spray paint with the car, will not fall, the premise is to clean up the original level, remember that is spray, not brush.

- Q: How to sell aluminum and plastic

- One kilogram of two dollars around it!

- Q: Home improvement, trouble annoying. Really know how much. Members of the senior, trouble to answer, the more detailed the better! To be easy to clean. Not sticky fumes. Heat is not flammable. So clean. The strength is slightly better.

- According to reports, the roller coated aluminum slab color bright, but only plain, and more so contaminated with smoke, relatively difficult to care; film is covered in a layer of film, color directly on the film, The This film has two kinds of imported and domestic, its thickness also affects the service life of aluminum plate. Drawing is a pattern processing, relatively beautiful.

- Q: Kitchen ceiling with aluminum or aluminum plate is good? Which brand in Jinan, the higher cost?

- Now the kitchen ceiling is mostly hanging aluminum plate, is the integrated ceiling, upstairs that aluminum-plastic ceiling ceiling per square cost of about 60-70 yuan is not down, I am a carpenter, do aluminum plate ceiling light wages are To 50 yuan a square, there are materials, aluminum plate a medium 80 yuan a, a 2.88 square, but also with 9% rendering, but also Wan Nengjiao, keel, glass glue, nails, Medium material with a piece of material almost 150 yuan a square, but also freight, aluminum buckle board more convenient to buy the place there are installed workers,

- Q: Whether the aluminum plate is non-combustible material

- Can provide non-combustible grade aluminum composite plate material, but can not say that aluminum-plastic plate is non-combustible material.

- Q: I was doing aluminum-plastic board, but the company did not pay for the site, there is no other easy to use free platform ah?

- You can open a personal online banking, online transfer transfer can be achieved

Send your message to us

Punched / Perforated Aluminum Panel for Aluminum Wall Facade

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 60000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords