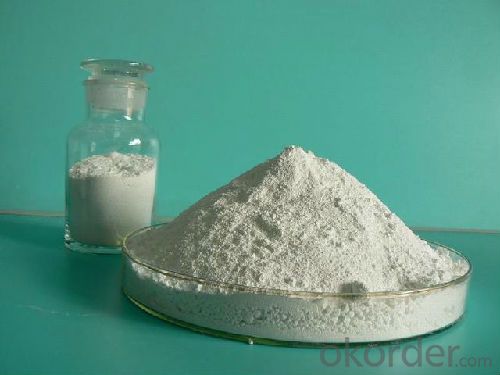

Professional Titanium Dioxide Used for Masterbatch

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 140000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Titanium Dioxide Used for Masterbatch Professional Supplier in China

1.Maily used on plastics,rubber

2.Manufacture

3.Rutile and anatase

4.High quailty,good price

coatings, printing ink, rubber, glass, leather, cosmetics, soaps, plastic and paper making etc

Chemical substances | TiO2/ Rutile Type (R type) |

Appearance | white powder |

Packing | 25kg woven bag, 1000kg sack |

Main features | high purity, high purity, good whiteness, strong hiding power, low abrasion to processing equipments. |

Range of application |

FOR PAINT ,COATING INK ETC.. |

Item | R-908 |

TiO2 Content(%) | 94 |

Rutile content (%) | 99 |

Surface Treatment chemicals | Alumina,Zirconium |

The disposal of organic compounds | Have |

pH Value | 8.0-9.0 |

Density(g/cm3) | 4.05 |

105°C Moisture % | 0.3 |

Particle Size micron | 0.3 |

Oil Absorption (g/100g) max | 20 |

Resistivity (Ω-m) | 150 |

CIE L* | 98.5 |

b* | 1.8 |

Tint-reducing power (Reynold’snumber) | 1900 |

Pb.As.Hg.Cr6+heavy metal element | 10 |

PBB,PBDE | No |

Exterior&interior durability | excellent |

ISO591-1:2000 | R2 |

ASTM D476:00 | II,III,IV |

- Q: i could use details for swirl painting guitar from do you primer, what type of paint is used

- Swirl Painting

- Q: The main ingredients and the use of attention to the matter

- Pungent taste is mainly from formaldehyde, benzene, TVOC and other pollutants emit out, their hazards are: formaldehyde is a colorless and soluble irritant gas. Particleboard, MDF, plywood and other man-made sheet, adhesive and wallpaper is the main source of formaldehyde in the air, the release period of up to 3 to 15 years. Can be absorbed by the respiratory tract, formaldehyde on the human body with a long-term hazards, latent, hidden characteristics. Long-term inhalation of formaldehyde can cause nasopharyngeal carcinoma, throat cancer and other serious diseases. Benzene is a colorless, with a special aroma of gas. Glues, paints, paints and adhesives are the main source of benzene in the air. Benzene and benzene by the body after inhalation, there may be central nervous system anesthesia; can inhibit human hematopoietic function, so that red blood cells, white blood cells, thrombocytopenia, aplastic anemia increased; also lead to abnormal menstruation, fetal congenital Defects and so on. TVOC total volatile organic compounds, VOC, Votatile Organic Compound abbreviation, VOC in the indoor air as a heterogeneous pollutants, because of their separate concentration is low, but the type, generally not one by one, respectively, to TVOC said its total. TVOC includes benzene, toluene, butyl acetate, ethylbenzene, p-xylene, styrene, o-xylene, undecane and the like. Interior construction and decoration materials are the main source of TVOC in the air. Studies have shown that even if the indoor air in a single VOC content is lower than its limit, but a variety of VOC mixed and its interaction, so that the damage intensity increases. TVOC showed toxicity, irritation, can cause the body immune disorders, affecting the central nervous system function, dizziness, headache, drowsiness, weakness, chest tightness and other symptoms, may also affect the digestive system, loss of appetite, nausea, etc. Damage the liver and hematopoietic system, and even cause death.

- Q: I have a ceramic mug that is glossed and I want to paint over it but make it microwave and dishwasher safe. What kinds of paints would I use?

- Acrylic Paint Once you have cleaned the greenware, you are ready to begin painting. Acrylic ceramic paints are available in almost any shade or color known. Choose the paint colors and purchase a small array of paint brushes to allow you to cover both large and small areas. Depending on the type of paint chosen, it is generally recommended to paint three coats of paint on the surface of the greenware. Allow the paint to thoroughly dry between coats. Don't be discouraged if the paint colors look extremely pale when applied to the greenware as the firing process will bring out the true colors. Now that you have applied three coats of ceramic paint to the surface of the greenware, return the painted item to your ceramic shop to be fired. The ceramic shop will fire the object and return it to you for glazing. Check under Sources for more info... Good luck!

- Q: What is the difference between home improvement paint and engineering paint?

- The so-called engineering paint, for everyone, may be a little knowledge, for some is not a professional person, hear some kind of so-called paint, only from the literal meaning to determine it, perhaps do not know how to paint, we Will think for a long time, and engineering paint is to let us a very headache of a variety of paint. Engineering paint is mainly for the construction industry services paint. Home paint a good understanding, specifically for the home decoration services of the paint varieties,

- Q: When i copy and paste stuff in paint white pixels are black Please help

- If i flow to photobucket, precise click on the image i admire, opt for replica, then flow to paint and open it and precise click and paste it places it in without issues. the only difference is i'm not utilising CtrlV. attempt this and see if it makes a distinctive to not use Ctrl-V If it nevertheless would not paintings then attempt saving the report on your computing gadget's hard stress and then copying it into paint.

- Q: What is the difference between water-based ink and ink?

- Water-based ink is referred to as ink, flexible version of water-based ink, also known as liquid ink, which is mainly composed of water-soluble resin, organic pigments, solvents and related additives by grinding. Water-based ink is particularly suitable for tobacco, wine, food, beverages, medicines, children's toys and other sanitary conditions require strict packaging and printing products.

- Q: What are the types of ink used in inkjet printers?

- Pigment Ink Pigment The colorant of the ink is a pigment that is insoluble in water and is suspended in water by means of a dispersant, so it is an opaque liquid. In other words, the first solid pigment grinding into very small particles, dissolved in a special water solvent. And dye ink into the media to form the principle of color exactly the opposite, it is attached to the media through the color of the surface to the hair color. Pigment ink chemical stability and optical stability, water resistance and light resistance, and high security, print color sharpness and high density. Although the water will penetrate the paper when printing, but the pigment is adsorbed by the paper and no longer dispersed in the water, will remain on the surface of the paper to form a stacking layer, hiding power, the requirements of the paper to reduce, so to achieve high density and high Sharpness of the print.

- Q: I paint a lot of paint by nubers but yet I don't seem to be able to paint without them? Help?

- Do you know how to draw? Do you understand shapes, colors, and how to make a complete picture? Do you understand composition and light quality? If you don't then it's no wonder you don't know how to paint without someone doing all the hard work for you. If you're actually interested in learning how to actually paint, then I suggest finding someone to teach you or looking up references and resources to help you.

- Q: Paint, PE and, PU paint, what is the difference

- Polyurethane coating (PU) its advantages: 1, fullness, hardness, transparency, have a better performance 2, stable performance, product stability 3, with other varieties of paint with, to make different performance It is a very good combination of excellent performance. The most widely used.

- Q: Paint pigment dyes What is the difference

- Paint: Paint and pigment are the same, the pigment is a formal chemical name. Dispersed in the solvent (which can be water or organic solvent) was suspended in the coloring agent called paint, sub-organic / inorganic two, color calm, poor transparency , But the light / redox performance is excellent. Most of the paintings of Chinese painting or oil painting are paint.

1. Manufacturer Overview

| Location | Langfang City,Hebei Province,China |

| Year Established | 2007 |

| Annual Output Value | US$10 Million - US$50 Million |

| Main Markets | North America, Domestic Market, South America, Western Europe, Mid East |

| Company Certifications | ISO9001;IS014001 Certificate |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao Port |

| Export Percentage | |

| No.of Employees in Trade Department | 5 - 10 People |

| Language Spoken: | English; Chinese; Spanish |

| b) Factory Information | |

| Factory Size: | 1,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Titanium Dioxide,White Carbon Black,Lithopone,Zinc Oxide,Barium Sulphate,Manganese Carbonate |

| Product Price Range | Average |

Send your message to us

Professional Titanium Dioxide Used for Masterbatch

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 140000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords