Titanium Dioxide CR350 for Plastic

- Loading Port:

- Guangzhou Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1*20fcl m.t.

- Supply Capability:

- 140,000MT m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description for Titanium Dioxide

Tio2 CR350 is designed to exceed today’s expectations for a titanium dioxide and set tomorrow’s standard in plastics formulations. The product is designed for formulators searching for a single grade of Tio2 with performance covering a broad range of plastics end uses.CR350 provides a matchless combination of excellent dispersion and processing, minimal volatile content, minimal interaction with polymer additives, durability and the brightness only a chloride-produced rutile Tio2 can provide.CR350 is the only Tio2 available that can offer such an exceptional set of properties.

TDS of the CR350

| Property | Index |

| Tio2,wt%,min | 95 |

| Specific Gravity | 4.1 |

| Color CIE L* | 99.0 |

Suggest for Use for Titanium Dioxide :

CR350 is optimized for polyolefin and ABS applications.CR350 allows a plastics formulator to design products that can be used in diverse applications ranging from general purpose plastics, durable/non-durable plastics and high quality products with critical end use applications.CR350 demonstrates excellent dispersion, marvelous processibility, exceptionally low volatility and enhanced durability. This combination of functions in one Tio2 make CR350 the prime choice for high temperature cast films, exterior films and general purpose applications while providing excellent assurance against discoloration.

CR350 Technologies pioneered the development of products that provide high opacity and blue undertone. This optical performance is something that is expected from Tio2 products.CR350 continues TITANIUM Technologies’ commitment to produce a Tio2 that can provide bright blue and clean appearance to plastics.

The CR350 rface allows for exceptional processing even in highly loaded Tio2 PE systems. Unique CR350 chemistry permits the product to adsirable masterbatch viscosities in a wide variety of polyolefin based resins. This fuction allows a formulator to minimize the Tio2 impact on melt properties during processing and end use applications.

Safety of Titanium Dioxide Powder :

As a matter of good industrial hygiene, gloves and safety glasses with side shields or better eye protection should be worn when handing Tio2,For more information, refer to the MSDS.

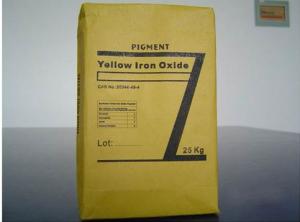

Packing Details of Tio2 :

25kg/bag, or 50kg/bag, even 1MT/bag will according to your need. the bag can be PP bag or paper bag. One 20 Feet container can be load 20MT with pallet , if without pallet , can load 22 MT.

Product Storage Titanium Dioxide Powder :

The shelf of CNBM Tio2 is indefinite as the material is kept from direct contact with moisture.

- Q: How much is a kilogram of paint

- Wuxi City Transit anti-corrosion paint, depending on the price of different varieties, the lowest 9.5, the highest 100 +

- Q: Whats the difference in the use of acrylic paints, compared to oil paints ?

- Generally speaking, acrylic paints are much faster to dry than oil paints so if you have a big art assignment that is due quite soon, it is better to use acrylics than oils. Otherwise, oils, because of their slow drying time, are easier to blend colours with as well as the fact that the colours stay the same. For acrylics, the colors dry slightly darker than before. Acrylic paint is really good to use in conjunction with acrylic mediums such as the retarding medium to slow down the drying process, as well as the binder medium (basically a substitution for water because water dilutes the paint too much). For texture, impasto is the way to go. Oh, and acrylics are definitely easier to deal with after painting because you can easily clean your brushes with water and soap (water-based), but oils, you have to use turpentine or special cleaning medium to get rid of the paint off the brushes.

- Q: Car antifreeze yellow and red color What is the difference

- Brand is not the same, the color of antifreeze is not the same. Now the antifreeze is generally green, mostly green. Red Blue.

- Q: What is the color on the model? Paint or watercolor paint? Hit the water out of color

- Basically can be divided into three types: water-based paint (acrylic paint), oily paint (enamel), oily paint (nitro) these three kinds of coating properties are different, understand their characteristics, the fans made model It would be helpful to choose a model paint for painting.

- Q: Cotton clothes on how to clean the paint above

- Use solvent: Remove the paint, you can use solvent gasoline, days that water, xylene, cyclohexanone, butyl and other solvents.

- Q: What is wood dyeing technology?

- Wood dyeing is a combination of dyes and wood chemical or physical chemistry, so that the wood has a certain color of the processing process is to improve the quality of wood surface, improve the visual characteristics of wood and increase the value of wood an important means. Wood dyeing by dye dyeing, chemical coloring and pigment coating. Wood dyeing is an important part of wood processing and utilization. Wood dyeing according to the solvent is divided into water-soluble dye dyeing, alcohol-soluble dye dyeing and oil-soluble dye dyeing, according to the dyeing method is divided into deep staining and surface staining. Deep dyeing is mainly used for processing veneer and wood, such as veneer veneer dyeing and technical wood veneer dyeing. Surface dyeing is the use of spraying, brushing or leaching method to deal with the surface of wood products.

- Q: What is the difference between polymer cement waterproof coating and polymer cement-based waterproof coating?

- It can be used in wet or dry masonry, mortar, concrete, metal, wood, hard plastic, glass, gypsum board, foam board, rubber, etc. For old and new buildings and structures (eg houses, underground works, Tunnels, bridges, pools, reservoirs, etc.) can be used, but also can be used as a binder. Particularly suitable for basement, underground tunnels, bathrooms, pools, etc., especially wet and long-term immersion in the water under the conditions of construction....

- Q: Favorite Leonardo Da Vinci painting? Why?

- I think Gioconda is just a must

- Q: How to use paint properly

- Home decoration selection paint a variety of ways, you can from the room decoration parts, finishes, chemical composition up, decoration can be selected according to their own requirements.

- Q: Who knows that the coating on the aluminum plate from the role of anti-oxidation and corrosion resistance of the kind of water-based paint is the kind of paint? Where there is a recipe to sell the best I can produce their own! Please give pointers

- Fluorocarbon baking paint, is ultra-durable baking fluorocarbon paint, fluorine resin as the main component, fluorocarbon baking paint for the spray factory paint production line design, with excellent durability, protection, lasting and so excellent performance.

1. Manufacturer Overview

| Location | GuangDong, China |

| Year Established | 1987 |

| Annual Output Value | Above US$100 Million |

| Main Markets | North America; South America; Eastern Europe; Southeast Asia; Africa; Oceania; Mid East; Eastern Asia; Western Europe; Southern Europ; South Asia |

| Company Certifications | REACH, ROSH,SVHC 53 Items Certificate ,SGS,CIQ,ISO9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Huang Pu Port |

| Export Percentage | 51% - 60% |

| No.of Employees in Trade Department | Above 100 People |

| Language Spoken: | English; Chinese;Spainsh; Farsi;French;German |

| b) Factory Information | |

| Factory Size: | Above 110,000 square meters |

| No. of Production Lines | Above 3 |

| Contract Manufacturing | Design Service Offered; Buyer Label Offered |

| Product Price Range | Rock Bottom Price With Best Quality |

Send your message to us

Titanium Dioxide CR350 for Plastic

- Loading Port:

- Guangzhou Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1*20fcl m.t.

- Supply Capability:

- 140,000MT m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords