Printing Tinplate Coils With Prime Quality for 0.29mm

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Printing Tinplate Coils With Prime Quality for 0.29mm

1.Structure of Description

Printing Tinplate Coils With Prime Quality for 0.29mm is one of the metal packing materials, which is widely used for making painting cans ,chemical package cans , electrical cable ,battery and metal printing etc.

2. Main Features

Steady and high quality

Fast shipment

Good experience for export work

For the surface, Plate uniform in thickness,uniform and smooth tin coating, without flaws,rusts,scratch,wave,nick of tin coating etc.

Price competitive

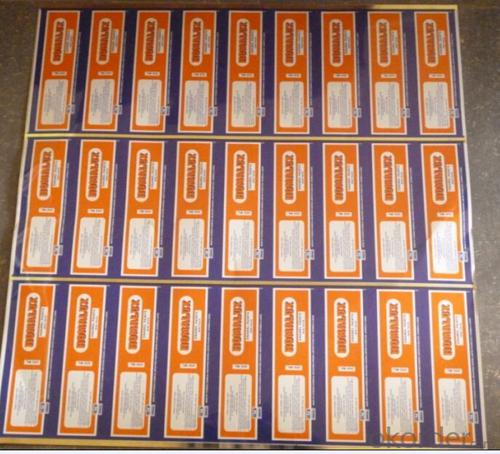

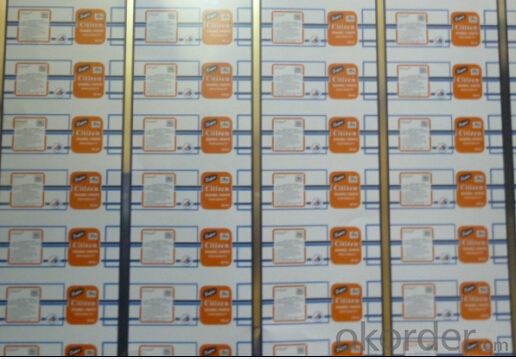

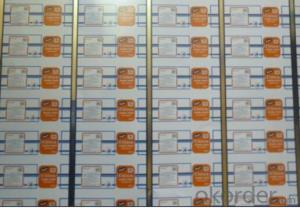

3. Images

4. Specification

Standard : GB2520-2000 ,JIS G3303

Steel type : SPCC

Coating : 2.8/2.8

Surface: Bright, Stone ,

Thickness:0.29

Width :600MM~1000MM

Temper : T1~T5

Package: tinplate wrapped completely with an inner cover of plastic or waterproof papers with vorners protected with metal angels.

5.FAQ

A. What is the package of tinplate? (Referred as below)

For sheets, thin plastic film + rust-proof paper + metallic cover + metallic angles+ steel band strips + fumigated wooden pallet.

For coil, thin plastic film + rust proof paper + metallic cover + steel band strips + fumigated wooden pallet

B. The surface of tinplate could you supply?

Stone finish, Bright finish, Matte finish, Silver finish

C. What quantity is the minimum order of tinplate?

Usually, the minimum quantity is 25MT. For special case, consult with us.

D. Can it make to be BA or CA for annealing?

Yes, both can do with.

- Q: How is tinplate used in the pharmaceutical industry?

- Tinplate is commonly used in the pharmaceutical industry for packaging purposes. It is often used to make containers, such as cans or tubes, for storing and protecting medicines, ointments, creams, or other pharmaceutical products. Tinplate containers provide a durable and protective barrier against external elements, ensuring the integrity and safety of the medication. Additionally, tinplate's resistance to corrosion makes it a suitable choice for pharmaceutical packaging, as it helps to maintain the quality and efficacy of the products over an extended period.

- Q: How is tinplate affected by different types of cosmetics?

- Tinplate can be affected by different types of cosmetics due to their chemical composition. Certain cosmetics, such as those containing acidic or alkaline ingredients, can cause corrosion or discoloration on the tinplate surface. Additionally, prolonged exposure to certain cosmetics, especially those containing solvents or oils, can lead to the degradation of the protective coating on the tinplate, making it more susceptible to rusting. Therefore, it is important to choose cosmetics that are compatible with tinplate packaging to ensure its longevity and integrity.

- Q: Why do tin tins rust easily when they are opened?

- It turned out to be sealed and oxygen has been transpiring. When opening is oxidized (Fe2o3), there is rust.

- Q: How does tinplate perform in high-temperature applications?

- Tinplate performs well in high-temperature applications due to its excellent heat resistance. It can withstand elevated temperatures without warping or deforming, making it suitable for various industrial and food processing operations that involve heat.

- Q: Can tinplate be used for signage?

- Yes, tinplate can be used for signage. It is a versatile material that can be easily shaped and printed on, making it suitable for various signage purposes.

- Q: Is to buy canned tinplate or aluminum

- Tinned food is usually made of tinplate, because the strength of tin is higher than that of aluminum cans, and the tin can not be deflatedAluminium is generally used in carbonated beveragesTin can be best served from the point of view of transport

- Q: Can tinplate be used for packaging of flammable liquids?

- Yes, tinplate can be used for packaging of flammable liquids. Tinplate is a durable and corrosion-resistant material that provides a strong barrier against external elements, including flammable liquids. It is commonly used in the packaging of various products, including flammable liquids, due to its ability to withstand the potential hazards associated with these substances.

- Q: How does tinplate perform in terms of insulation properties?

- Tinplate has poor insulation properties due to its high thermal conductivity, meaning it is not an effective insulator and allows heat and electricity to easily pass through.

- Q: What are the advantages of using tinplate for promotional items?

- There are several advantages of using tinplate for promotional items. Firstly, tinplate is a durable material that can withstand wear and tear, making it ideal for long-lasting promotional products. Secondly, tinplate is highly customizable, allowing for various shapes, sizes, and designs to be created, enhancing the visual appeal of the promotional items. Additionally, tinplate can be easily printed on, enabling businesses to display their branding and messaging effectively. Lastly, tinplate is eco-friendly as it is recyclable, making it a sustainable choice for businesses concerned about their environmental impact.

- Q: What is the difference between food grade tinplate and ordinary chemical tinplate? What is the difference between MR material and SPCC?

- Tinned food grade and non food grade. The main brands are MR and SPCC. because the meat food will be wall mounted in contact with food tin coated with two layers of yellow food, the food is yellow anti solvent, anti general acid-base, thus ensuring the safety of food packaging containing iron. The food there is no absolute security argument, now the technology has been fully capable of ensuring the safety of food containing.MR's impurity is a little more than SPCC, and the price is a little high. It's OK to use SPCC to spread two layers of food on the outside

Send your message to us

Printing Tinplate Coils With Prime Quality for 0.29mm

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords