Printing Tinplate Coils With Prime Quality for 0.19mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

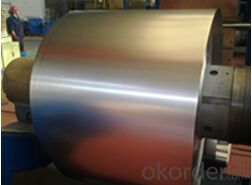

Printing Tinplate Coils With Prime Quality for 0.19mm

1.Structure of Description

Printing Tinplate Coils With Prime Quality for 0.19mm is one of the metal packing materials, which is widely used for making painting cans ,chemical package cans , electrical cable ,battery and metal printing etc.

2. Main Features

Steady and high quality

Fast shipment

Good experience for export work

For the surface, Plate uniform in thickness,uniform and smooth tin coating, without flaws,rusts,scratch,wave,nick of tin coating etc.

Price competitive

3. Images

4. Specification

Standard : GB2520-2000 ,JIS G3303

Steel type : SPCC

Coating : 2.8/2.8

Surface: Bright, Stone ,

Thickness:0.31

Width :600MM~1000MM

Temper : T1~T5

Package: tinplate wrapped completely with an inner cover of plastic or waterproof papers with vorners protected with metal angels.

5.FAQ

A. What is the package of tinplate? (Referred as below)

For sheets, thin plastic film + rust-proof paper + metallic cover + metallic angles+ steel band strips + fumigated wooden pallet.

For coil, thin plastic film + rust proof paper + metallic cover + steel band strips + fumigated wooden pallet

B. The surface of tinplate could you supply?

Stone finish, Bright finish, Matte finish, Silver finish

C. What is the shipment date?

Around 50- 60days.

- Q: Can tinplate packaging be used for toy products?

- Yes, tinplate packaging can be used for toy products. Tinplate is a durable and versatile material that provides a protective barrier, making it suitable for packaging various types of toys. Additionally, tinplate can be easily printed on, allowing for attractive and customized designs for toy packaging.

- Q: How is tinplate used in the confectionery industry?

- Tinplate is commonly used in the confectionery industry for packaging purposes. It provides a protective and airtight barrier, ensuring the freshness and quality of confectionery products. Tinplate cans or containers are often used for storing chocolates, candies, and other sweets, keeping them safe from moisture, light, and external contaminants. Additionally, tinplate's versatility allows for attractive and customizable designs, enhancing the visual appeal of confectionery packaging.

- Q: Cookies with tinplate packaging has what advantage

- 1. good mechanical properties: tinplate cans relative to other containers, such as plastic, glass, paper containers and strength, and good rigidity, it is not easy to break. It is not only used for small sale packing, but also the main container for large transportation package. 2. excellent barrier: Tin than any other...

- Q: Can tinplate be used for packaging frozen foods?

- Yes, tinplate can be used for packaging frozen foods. Tinplate is a commonly used material for food packaging due to its durability, resistance to corrosion, and ability to maintain product freshness. It provides a reliable barrier against moisture and oxygen, making it suitable for preserving the quality of frozen foods.

- Q: Can tinplate be used for packaging fragile items?

- Yes, tinplate can be used for packaging fragile items. Tinplate is a strong and durable material that provides excellent protection against damage. Its resistance to impact and ability to withstand pressure make it suitable for packaging fragile items safely. Additionally, tinplate's ability to resist corrosion ensures that the packaging remains intact and protects the fragile items throughout the shipping or storage process.

- Q: How is tinplate coated with organic materials?

- Tinplate is typically coated with organic materials through a process called lacquering or varnishing. The organic coating, usually a resin-based material, is applied to the tinplate surface in a controlled manner, forming a protective layer that prevents corrosion, enhances durability, and provides a decorative finish.

- Q: Can tinplate be used for high-temperature applications?

- No, tinplate is not suitable for high-temperature applications due to its low melting point.

- Q: How is tinplate affected by extreme temperatures?

- Tinplate is minimally affected by extreme temperatures due to its high melting point and excellent heat resistance properties. It remains stable and does not undergo significant changes in its physical or chemical properties even in extremely hot or cold conditions.

- Q: Can tinplate be used for art and sculptures?

- Yes, tinplate can be used for art and sculptures. Its malleability and durability make it a suitable material for creating various artistic forms and sculptures.

- Q: How is tinplate made?

- Tinplate is made by coating thin sheets of steel with a layer of tin through a process called electroplating. The steel sheets are first cleaned and then passed through an electrolyte bath where a direct current is applied. This causes tin ions in the electrolyte to bond with the steel, forming a layer of tin on its surface. The resulting tin-coated steel sheets are then rolled into coils, ready to be used in various applications like food cans and packaging materials.

Send your message to us

Printing Tinplate Coils With Prime Quality for 0.19mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords