Prime Quality Tinplate for Caps and Ends

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Description

Electrolytic Tinplate Sheets is one of the metal packing materials, which is widely used for making painting cans ,chemical package cans , electrical cable ,battery and metal printing etc.

2. Main Features

Steady and high quality

Fast shipment

Good experience for export work

For the surface, Plate uniform in thickness,uniform and smooth tin coating, without flaws,rusts,scratch,wave,nick of tin coating etc.

Price competitive

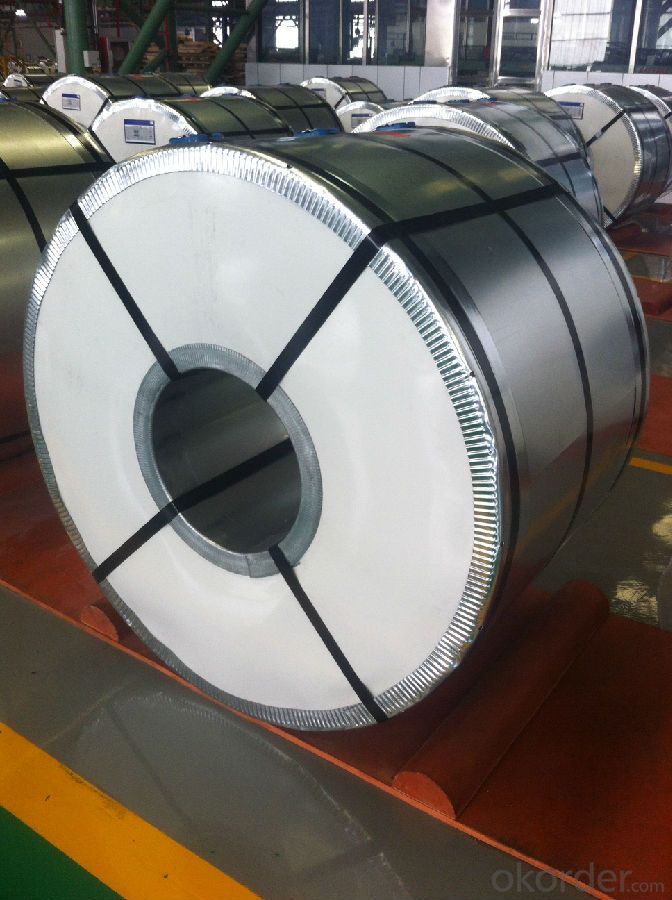

3. Images

4. Specification

Standard : GB2520-2000 ,JIS G3303

Steel type : SPCC

Coating : 2.8/2.8

Surface: Bright, Stone ,

Thickness:0.31

Width :600MM~1000MM

Temper : T1~T5

Package: tinplate wrapped completely with an inner cover of plastic or waterproof papers with vorners protected with metal angels.

5.FAQ

A. What is the package of tinplate? (Referred as below)

For sheets, thin plastic film + rust-proof paper + metallic cover + metallic angles+ steel band strips + fumigated wooden pallet.

For coil, thin plastic film + rust proof paper + metallic cover + steel band strips + fumigated wooden pallet

B. The surface of tinplate could you supply?

Stone finish, Bright finish, Matte finish, Silver finish

C. What quantity is the minimum order of tinplate?

Usually, the minimum quantity is 25MT. For special case, consult with us.

D. Can it make to be BA or CA for annealing?

Yes, both can do with.

- Q: How does tinplate packaging handle exposure to moisture?

- Tinplate packaging is highly resistant to moisture and provides an effective barrier against it. The tin coating on the steel substrate prevents direct contact between the metal and moisture, protecting the contents inside. This makes tinplate packaging suitable for various products, including food and beverages, as it maintains their quality and prevents spoilage caused by moisture.

- Q: How is tinplate tested for corrosion resistance?

- Tinplate is tested for corrosion resistance through various methods, including salt spray testing, electrochemical impedance spectroscopy, and weight loss analysis. These tests evaluate the ability of tinplate to withstand exposure to corrosive environments and provide insights into its protective properties.

- Q: The difference between a matte tin plate and a bright tin plate

- Silver tinplate:Silver surface processing refers to the original plate in plating passivation treatment after reflow treatment and the surface has a unique stable luster; after printing and coating, the operation of creating a gorgeous and elegant atmosphere, used in the manufacture of advanced art cans, nuts, etc..

- Q: What are the main applications of tinplate in the textile industry?

- Tinplate is commonly used in the textile industry for various applications such as packaging, labeling, and storage of textile products. It provides a protective and durable coating that prevents rust and corrosion, ensuring the longevity of the textile items. Tinplate is also utilized in the manufacturing of sewing machine parts, including bobbins and needles, due to its strength and resistance to wear and tear. Additionally, tinplate is employed for the production of textile dyeing and printing equipment, as it can withstand high temperatures and chemical reactions involved in these processes.

- Q: How does tinplate contribute to the durability of construction materials?

- Tinplate contributes to the durability of construction materials by providing a protective layer that is resistant to corrosion and rust. This helps to prevent deterioration and prolongs the lifespan of the materials, making them more durable and able to withstand harsh environmental conditions.

- Q: What are the main applications of tinplate in the aerospace industry?

- Tinplate is primarily used in the aerospace industry for manufacturing various components, such as fuel tanks, containers, and protective casings. Its corrosion resistance properties make it ideal for safeguarding against moisture and ensuring the longevity of these critical aerospace components. Additionally, tinplate's lightweight nature contributes to the overall weight reduction of aircraft, enhancing fuel efficiency and performance.

- Q: What are the benefits of using tinplate for paint cans?

- Tinplate offers numerous benefits for paint cans, including its excellent durability, resistance to corrosion, and ability to maintain product quality by providing a protective barrier. Additionally, tinplate is recyclable, making it a sustainable choice for packaging.

- Q: Can tinplate packaging be used for home decor products?

- Yes, tinplate packaging can be used for home decor products. Tinplate is a versatile material that can be molded into various shapes and sizes, making it suitable for packaging home decor items such as candles, ornaments, and small decorative accessories. Additionally, tinplate packaging offers a unique and aesthetically pleasing appearance that can enhance the overall presentation of home decor products.

- Q: How does tinplate packaging contribute to product protection against odors?

- Tinplate packaging contributes to product protection against odors due to its excellent barrier properties. The tin coating on the steel substrate prevents the penetration of external odors, ensuring that the product inside remains fresh and uncontaminated. Additionally, tinplate packaging provides a hermetic seal, preventing the escape of any odors from the product, thus preserving its quality and integrity.

- Q: What are the main factors influencing the growth of the tinplate industry?

- The main factors influencing the growth of the tinplate industry include increasing demand for packaged food and beverages, expanding urbanization and industrialization, advancements in technology leading to improved production processes, and the growing awareness about the benefits of metal packaging such as durability, recyclability, and food safety. Additionally, economic growth in emerging markets and the rising disposable income of consumers are also driving the growth of the tinplate industry.

Send your message to us

Prime Quality Tinplate for Caps and Ends

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords