Prime Grade Tinplate For Food Cans, MR Material

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

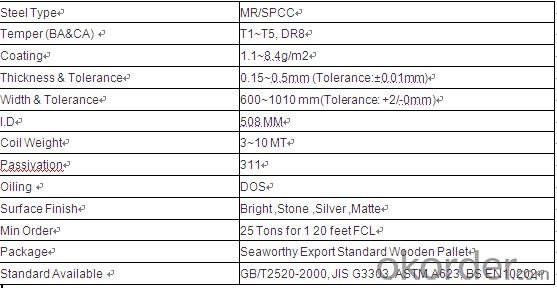

Specification

1.Usage

Tinplate is widely used for making all types of containers, containing industrial usage such as paint can, oil can, aerosol cans etc., and food cans like milk powder cans, tomato paste can, dry food cans etc.

2. Tinplate production Process

cold rolling mill---degreasing production line---tension leveler---batch annealing furnaces/continuous annealing line---tin coating line---cutting line---stock area

3. Specification

standard: GB/T2520, JIS G3303, DIN EN10202

Material: MR /SPCC

Thickness available: 0.16-0.50MM

Width available: 600~1050MM

Temper grade: T1 – DR8

Tin coating: ordinary 2.8g/2.8g, 5.6g/5.6g and others

Package: sea worthy export package.

Applications: Tin can for chemicals & paint cans, industrial cans, food cans

4.our production area picture

5. FAQ

a. what's the annual output?

about 500,000 tons per year.

b. where's the raw matrial from?

our hot rolled coil is purchased from Capital Steel and other state owned mill, with quite good quality.

c. how long is the delivery time?

normally for SPCC about 45~55 days, while 65~75 days for MR material

d. what's your advantage than other supplier?

we have overseas warehouse all over the world, like Saudi Arabia, Oman, UAE, Kuwait, Russia, South Africa etc.

e.how to control the quality during production process?

inside our workshop, we have MES syestem. It will show the status of each production step.

- Q: What kind of material is tinplate?

- Tin is mainly used to prevent corrosion and rust. It will be the steel strength and formability and corrosion resistance of tin soldering, and beautiful appearance with a material, corrosion resistant, non-toxic, high strength and good ductility properties

- Q: How is tinplate coated for toys and games?

- Tinplate is typically coated for toys and games using a process called electroplating, where a thin layer of tin is deposited onto the surface of the metal. This electroplating technique helps enhance the appearance, durability, and corrosion resistance of tinplate, making it suitable for various toy and game applications.

- Q: What are the typical manufacturing processes for tinplate products?

- The typical manufacturing processes for tinplate products include coil preparation, coil cleaning, annealing, coating, temper rolling, cutting, and forming.

- Q: How does tinplate packaging contribute to product protection against contamination?

- Tinplate packaging provides a protective barrier that helps prevent contamination of products. The tin coating on the steel surface acts as a barrier against moisture, oxygen, and other external factors that can potentially contaminate the product. This enhanced protection ensures the product's integrity and extends its shelf life by minimizing the risk of spoilage or degradation caused by external contaminants. Additionally, tinplate packaging is resistant to corrosion, further safeguarding the product from any potential contamination that could occur due to rust or other metal-related issues.

- Q: What are the main challenges in tinplate welding and soldering?

- Some of the main challenges in tinplate welding and soldering include ensuring proper surface preparation to achieve good adhesion, dealing with the thin gauge of tinplate which can make it more prone to warping or burning, and finding suitable fluxes and solder alloys that can effectively bond with tinplate due to its unique properties. Additionally, the presence of tin oxide on the surface of tinplate can hinder the formation of strong welds or solder joints, requiring special techniques or treatments to address this issue.

- Q: What are the different tinplate surface finishes?

- The different tinplate surface finishes include bright, stone, matte, and silver.

- Q: How is tinplate tested for quality control?

- Tinplate is tested for quality control through various methods such as visual inspection, chemical analysis, and mechanical testing. Visual inspection involves checking for any defects or imperfections on the surface of the tinplate, ensuring it meets the required standards. Chemical analysis is performed to determine the composition of the tinplate, ensuring it contains the appropriate levels of tin and other alloying elements. Mechanical testing involves subjecting the tinplate to various stress tests to assess its strength, ductility, and resistance to corrosion. These quality control measures help ensure that tinplate meets the necessary standards for its intended use.

- Q: How does tinplate compare to plastic in terms of sustainability?

- Tinplate is generally considered more sustainable than plastic due to its recyclability and lower environmental impact throughout its life cycle. Unlike plastic, tinplate is easily and endlessly recyclable without any loss in quality, making it a preferred choice for packaging materials. Additionally, tinplate has a lower carbon footprint, as it requires less energy to produce and emits fewer greenhouse gases during manufacturing. On the other hand, plastic often ends up in landfills or as litter, taking hundreds of years to decompose and contributing to pollution and wildlife harm. Overall, tinplate offers better sustainability attributes and is a more environmentally friendly option compared to plastic.

- Q: Can tinplate be embossed or engraved?

- Yes, tinplate can be embossed or engraved.

- Q: What are the environmental impacts of using tinplate?

- The environmental impacts of using tinplate include resource depletion, energy consumption, greenhouse gas emissions, and waste generation. Tinplate production requires the extraction of raw materials, such as iron and tin, which can lead to habitat destruction and ecosystem disruption. The manufacturing process is energy-intensive, contributing to carbon dioxide emissions and climate change. Additionally, the disposal of tinplate products after use can contribute to waste accumulation in landfills. However, tinplate is also recyclable, which can mitigate some of its environmental impacts if proper recycling practices are followed.

Send your message to us

Prime Grade Tinplate For Food Cans, MR Material

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords