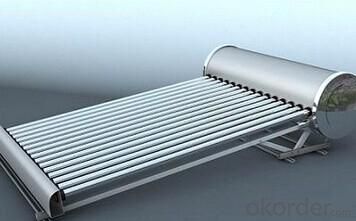

Eos Solar Collectors Pressurized Heat Pipe Solar Water Heater System 2024 New Design

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 6000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of Non-Pressure Solar Water Heater:

Non-pressure Solar Heater is one of the most economical solar water heating device with pretty high efficiency at the same time. It consists of hot water storage tank, solar vacuum tubes with mouth plug in storage tank, and bracket supporting tank and tubes.When cold water in evacuated tubes is heated with solar irradiation, as the specific gravities of hot water and cold water are different, hotter water goes upward to storage tank and colder water goes downward to glass tubes. through this continuous circulation, the cold water in storage tank will be gradually heated till sunset.

Specialty:

1. High thermal performance and working temperature: the heat exchanging rate even in winter can up above 55%.

2. Heat collecting efficiency is at least 20% above common solar systems.

3. Work in all day and all season: no matter any corner of the world, this system can work well even -40℃ to avoid the tube freezing problem.

4. Reliability: No water following through the tube, so water scale can not generate and tube cracks could be avoided, the system still can keep working even with some damaged tubes.

5. It can connect with water tap and work automatically with pressure0.6Mpa, bring enjoyable washing experience.

6. Safety: P/T valve would release pressure and temperature to protect tank..

Technical Specification:

1. Outer tank material: SUS304 stainless steel or powder coated color steel

2. Inner tank material: 1.2mm thick SUS304 food grade stainless steel ( Optional material SUS316L)

3. Vacuum tube material: borosilicate glass 3.3; AL-SS-CU absorb coating, with copper heat pipe inside

4. Frame material: 1.2mm thickness stainless steel

5. Insulation material: 55mm thickness polyurethane

6. Suitable for mains pressure water(up to 8 bar/116psi)

7. Easy plug-in installation

8. Install the T/P valve on the pressurized tank

9. Seal material: Stabilized High Temperature Silicon

Outer tank material: SUS304 stainless steel or powder coated color steel

Inner tank material: 1.2mm thick SUS304 food grade stainless steel ( Optional material SUS316L)

Vacuum tube material: borosilicate glass 3.3; AL-SS-CU absorb coating, with copper heat pipe inside

Frame material: 1.2mm thickness stainless steel

Insulation material: 55mm thickness polyurethane

Suitable for mains pressure water(up to 8 bar/116psi)

Easy plug-in installation

Install the T/P valve on the pressurized tank

Seal material: Stabilized High Temperature Silicon

19. Vacuum Tube | 20. Size (mm) | 21. Φ47*1500 / Φ58*1800 / Φ70*2100 | |||||

22. Tube (pcs) | 23. 10 / 12 / 15 / 18 / 20 / 22 / 24 / 30 / 36 / 42 | ||||||

24. Material | 25. Borosilicate 3.3 glass, magnetron spluttering selective coating | ||||||

26. Coating | 27. Single-target AL-N/AL or Three-target AL/N-Cu-SS | ||||||

28. Water Tank | 29. Capacity | 30. 80L ~ 500L for hot water storage tank | |||||

31. Inner tank | 32. Food-grade stainless steel SUS304-2B / SUS316 | ||||||

33. Insulation | 34. High-density polyurethane foam with 70~80 hour heat preservation | ||||||

35. Tank shell | 36. Food-grade stainless steel SUS304-2B | ||||||

37. Bracket | 38. Shaped strong aluminum alloy structure adaptable for flat or slope roof | ||||||

39. Accessories | 40. Anti-aging silicon seals, Dustproof seals, Air-vent cap, Stainless screws | ||||||

41. Auxiliary Devices | 42. Assistant tank, Intelligent controller, Electrical heater, Magnesium anodes | ||||||

43. Tilt Angle | 44. 25 ~ 50° | ||||||

45. Water Output | 46. 45 - 95°C | ||||||

47. Hail Resistance | 48. Φ25mm diameter | ||||||

49. Model Number | 50. Solar Vacuum Tube | 51. Tank 52. Liter | 53. System 54. Liter | 55. Container Loading Qty /sets | |||

56. Size /mm | 57. Qty /pcs | 58. 20GP | 59. 40GP | 60. 40HQ | |||

61. VNS-58SA12-100 | 62. Φ58*1800 | 63. 12 | 64. 100 | 65. 132 | 66. 58 | 67. 119 | 68. 140 |

69. VNS-58SA15-130 | 70. 15 | 71. 130 | 72. 170 | 73. 54 | 74. 108 | 75. 131 | |

76. VNS-58SA18-150 | 77. 18 | 78. 150 | 79. 198 | 80. 43 | 81. 86 | 82. 105 | |

83. VNS-58SA20-170 | 84. 20 | 85. 170 | 86. 223 | 87. 40 | 88. 80 | 89. 97 | |

VNS-58SA24-200 | 24 | 200 | 263 | 35 | 70 | 85 | |

VNS-58SA30-250 | 30 | 250 | 329 | 28 | 56 | 68 | |

VNS-58SA36-300 | 36 | 300 | 395 | 23 | 47 | 57 | |

Product Show

Our Services

1. OEM service

2. Warranty: 5 years

3. Considerable after sale service

Color steel Compact pressure Thermal solar heater

FAQ:

1. What’s the delivery time?

10 days after receiving deposit.

2. How long is the warranty?

5 years for whole system, 1 year for accessory

3. What’s your production capacity?

6000sets/month

4. What’s the MOQ?

1 set.

5. What’s your payment term?

Container: 30% T/T in advance for deposit, 70% T/T before shipment for fist order.

70% T/T after seeing copy of B/L from second order

Sample: 100% T/T in advance

Other choices: L/C at sight.

6. What certifications do you have?

CE, SOLAR KEYMARK, SRCC and etc.

- Q: How do solar collectors impact energy bills?

- Solar collectors can significantly reduce energy bills by utilizing sunlight to generate electricity or heat water, thereby decreasing reliance on conventional energy sources. This renewable energy source helps to offset energy consumption, leading to lower electricity or heating costs and ultimately reducing energy bills.

- Q: How do solar collectors impact the value of a property?

- Solar collectors can significantly increase the value of a property by reducing energy costs, providing a sustainable energy source, and contributing to a greener and more efficient home.

- Q: Can solar collectors be used for heating car rental facilities and parking lots?

- Car rental facilities and parking lots can benefit from the use of solar collectors for heating purposes. These devices, also referred to as solar thermal systems, harness the sun's heat and convert it into usable thermal energy. This energy can then be utilized in various ways, such as heating buildings and providing hot water. To utilize solar collectors for car rental facilities and parking lots, they can be installed on rooftops or in close proximity to the buildings. This allows them to capture solar energy effectively. The collected energy can then be used to heat the interior spaces of the rental facilities, ensuring a comfortable environment for both customers and staff. Office areas and waiting rooms can be heated using this approach. Additionally, integrating solar collectors into the parking lot infrastructure can provide heating for the pavement during colder weather conditions. This helps to prevent ice formation and improves driving safety. By adopting solar collectors for heating purposes, businesses can reduce their reliance on traditional heating systems that rely on fossil fuels. This not only helps to combat climate change by reducing greenhouse gas emissions but also leads to long-term cost savings. Energy consumption is reduced, and dependence on non-renewable resources is lessened. Moreover, solar collectors require minimal maintenance and have a long lifespan, making them a sustainable and reliable heating solution for car rental facilities and parking lots.

- Q: Can solar collectors be used for heating ice melting systems?

- Yes, solar collectors can be used for heating ice melting systems. Solar collectors can capture energy from the sun and convert it into heat which can then be used to melt ice. This can be achieved by transferring the heat generated by solar collectors to the ice melting system, such as through the circulation of a heat transfer fluid.

- Q: Can solar collectors be used in combination with desalination systems?

- Yes, solar collectors can be used in combination with desalination systems. Solar energy can be harnessed to power the desalination process, providing a sustainable and renewable source of energy. This combination offers an environmentally friendly solution to address water scarcity by utilizing solar power to operate desalination systems and produce freshwater from saltwater sources.

- Q: Are there any zoning restrictions for solar collector installations?

- Yes, there are zoning restrictions for solar collector installations. These restrictions vary by location and are typically set by local government bodies. The rules may cover aspects such as setback requirements, height restrictions, and aesthetic guidelines to ensure that solar collectors are installed in a way that is compatible with the surrounding environment.

- Q: Can solar collectors be used for heating water in freezing temperatures?

- Yes, solar collectors can be used for heating water in freezing temperatures. While the efficiency of solar collectors may be reduced in extremely cold weather, they can still generate enough heat to warm water. Additionally, many solar water heating systems include features such as insulated pipes and heat exchangers that help prevent freezing and ensure the water remains hot. Moreover, antifreeze solutions are often used in the solar collectors to prevent freezing. Overall, solar collectors can still be an effective and reliable method for heating water even in freezing temperatures.

- Q: Are solar collectors suitable for countries with limited sunlight?

- Solar collectors are still suitable for countries with limited sunlight, although their efficiency may be reduced compared to countries with abundant sunlight. Solar collectors work by converting sunlight into usable energy, and even in countries with limited sunlight, there is still some level of solar radiation available throughout the year. In countries with limited sunlight, it is important to consider the type and design of solar collectors that are used. For instance, using solar thermal collectors that focus on capturing heat rather than generating electricity can be more beneficial in such regions. These collectors can be used for heating water or space heating, which can be a significant energy demand even in countries with limited sunlight. Additionally, advancements in solar technology have led to the development of more efficient solar collectors that can still generate energy even in low-light conditions. For example, some solar panels are designed to capture diffuse light, making them suitable for regions with limited direct sunlight. Furthermore, integrating solar collectors with other renewable energy sources, such as wind or hydro power, can help compensate for the limited sunlight and ensure a more reliable and sustainable energy supply. Therefore, while solar collectors may not be as efficient in countries with limited sunlight, they can still be a viable and valuable renewable energy option, especially when combined with other renewable sources and optimized for the specific conditions of the region.

- Q: Do solar collectors work in cold climates?

- Yes, solar collectors work in cold climates. While the efficiency of solar collectors can be slightly reduced in colder temperatures, they still generate electricity or heat by absorbing sunlight. Additionally, advancements in technology have made solar panels more effective in capturing and converting solar energy, making them increasingly viable in cold weather conditions.

- Q: How are solar collectors different from solar panels?

- Solar energy can be harnessed through the use of solar collectors and solar panels, although their purposes and functionalities differ. Solar collectors are specifically designed to capture and convert thermal energy from the sun into heat. These collectors are commonly used to heat water or air in residential, commercial, or industrial settings. They consist of tubes or pipes that circulate a heat transfer fluid, like water or antifreeze, absorbing the sun's heat and transferring it to a storage tank or directly to the desired application. Solar collectors are mainly utilized in solar water heating or space heating systems. On the other hand, solar panels, also known as photovoltaic (PV) panels, are used to directly convert sunlight into electricity. They are composed of multiple solar cells made of semiconductor materials, such as silicon, that generate electricity when exposed to sunlight. Solar panels are primarily used for generating electricity in residential, commercial, and utility-scale solar power systems. They can be mounted on rooftops, integrated into building materials, or installed as ground-mounted arrays. In conclusion, solar collectors are designed to capture and convert solar energy into heat, whereas solar panels are used to directly convert sunlight into electricity. Both technologies have important roles in harnessing solar energy and are employed in various applications to reduce reliance on conventional energy sources and promote sustainability.

Send your message to us

Eos Solar Collectors Pressurized Heat Pipe Solar Water Heater System 2024 New Design

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 6000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords