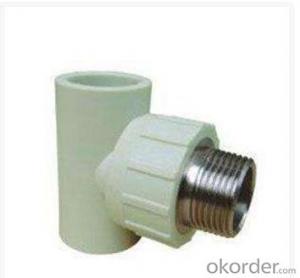

3/4 BSP PPR Plastic Pipe and Fittings for Household

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of Products

Place of Origin: Henan, China (Mainland)

Model Number: PE100

Material: PE

Specification: DN 20-mm~DN1200mm

Length: According to customer requirement

Thickness: SDR11/13.6/17

Standard: ISO

Color: many colors

Product name: Plastic Pipe

Application: house and garden

Usage: Family Decoration Industry

Certification: ISO Certificate

Feature: Lightweight

Size: Customized Size

Type: Round Pipe

Name: HDPE Plastic Pipe

Connection: Butt Fusion

size

Normal Sizes for CNBM PPR Pipe | ||||||

Outside Diameter(mm) | Wall Thickness(mm) | Package(m/bale) | ||||

S5 PN1.25MPa | S4 PN1.6MPa | S3.2 PN2.0MPa | S2.5 PN2.5MPa | |||

20 | 2 | 2.3 | 2.8 | 3.4 | 120 | |

25 | 2.3 | 2.8 | 3.5 | 4.2 | 120 | |

32 | 2.9 | 3.6 | 4.4 | 5.4 | 80 | |

40 | 3.7 | 4.5 | 5.5 | 6.7 | 60 | |

50 | 4.6 | 5.6 | 6.9 | 8.3 | 40 | |

63 | 5.8 | 7.1 | 8.6 | 10.5 | 24 | |

75 | 6.8 | 8.4 | 10.1 | 12.5 | 16 | |

Specification

1.Material: | PPR |

2.Color: | White, Gray, Green, or as you required. |

3.Size: | 20-110mm |

4.Logo: | CMAX or Customized |

5.MOQ | 500pcs |

6.Samples Time: | (1) 4-5days-If you want to customize your logo. |

(2) 1day-For our existing samples for reference. | |

7.OEM Accepted | Yes |

8.Certification available: | Yes |

9.Packing Details: | Weaving Bag |

10.Production Capacity: | 5,000,000pcs Per month. |

11.Payment Term: | (1) L/C, T/T, D/P |

Applications of PPR Pipe (white, gray):

1) Cold and hot water supply systems for civil and industrial constructions, e.g. in residential buildings, hospitals, hotels, school and office buildings, ship building

2) Drinking water systems and food industry pipe works

3) Central air conditioning system

4) Irrigating system for gardens and green houses

5) Public and sport facilities such as swimming pools and stadiums

6) For rainwater utilization systems

Packaging Details:

1. Large carton: 515 x 400x 220 Cubage: 0.04532 M3

Small carton: 390x255x250 Cubage: 0.0248 M3

2. PE poly bag+ carton Delivery Detail: 15 days/ 20" containers; 25 days/ 40HQ

FAQ

Q1: How Can I Get a Sample?

A1: You can get samples by communicate with our export sales.

Q2: How Long Is Delivery?

A2: Delivery time will be30-45days according to order quantity.

Q3: What Is The MOQ?

A3: MOQ depends on different items.

Q4: What Is Our Normal Payments Terms?

A4: Our normal payment terms now is: T/T, L/C or western union, MoneyGram.

- Q: How do plastic pipe fittings compare to polyethylene fittings?

- Plastic pipe fittings and polyethylene fittings are actually the same thing. Polyethylene is a type of plastic that is commonly used in pipe fittings due to its durability and resistance to corrosion. So, there is no significant difference between plastic pipe fittings and polyethylene fittings as they both refer to the same material.

- Q: TTP-PESI hole net steel belt composite pipe fittings need to be taken?

- The wire mesh and steel band composite plastic pipe is one of the achievements in the Ministry of construction's scientific and technological achievements. As a transportation pipeline, it can be widely used in petroleum, chemical, pharmaceutical, mining, municipal engineering and so on.

- Q: Can plastic pipe fittings be used in DIY projects?

- Yes, plastic pipe fittings can be used in DIY projects. They are commonly used for plumbing and irrigation systems, as they are easy to work with, affordable, and resistant to corrosion. However, it is important to ensure that the fittings are compatible with the specific type of plastic pipe being used and that they are installed correctly to ensure a secure and leak-free connection.

- Q: Are plastic pipe fittings resistant to ultraviolet (UV) rays?

- Yes, plastic pipe fittings can be resistant to ultraviolet (UV) rays. However, the level of resistance may vary depending on the type of plastic used in the fittings. Some plastics, such as PVC (polyvinyl chloride), are naturally more resistant to UV rays, while others may require additional additives or coatings to enhance their UV resistance.

- Q: Are plastic pipe fittings suitable for laboratory installations?

- Yes, plastic pipe fittings are suitable for laboratory installations. They are commonly used due to their durability, chemical resistance, and ease of installation. Plastic fittings are suitable for a wide range of laboratory applications and can effectively handle various chemicals and fluids.

- Q: Are plastic pipe fittings resistant to sulfuric acid?

- No, plastic pipe fittings are not resistant to sulfuric acid.

- Q: Are plastic pipe fittings compatible with electrofusion welding?

- Yes, plastic pipe fittings are compatible with electrofusion welding. Electrofusion welding is a commonly used method to join plastic pipes and fittings. It creates a strong, leak-proof connection by melting the pipe and fitting surfaces together using an electric current. Plastic pipe fittings, such as couplings, elbows, and tees, are specifically designed to be used with electrofusion welding techniques.

- Q: Are plastic pipe fittings resistant to impact damage?

- Yes, plastic pipe fittings are generally resistant to impact damage. They are designed to withstand various levels of force and impact, making them durable and less prone to damage compared to other materials. However, the level of impact resistance may vary depending on the specific type and quality of the plastic used in the fittings.

- Q: PE plastic pipe surface is concave, how could it happen?

- Pipe and pipe fittings should be placed in the construction site for a certain period of time after the connection, so that the pipe and pipe temperature is consistent

- Q: Can plastic pipe fittings be used for agricultural applications?

- Yes, plastic pipe fittings can be used for agricultural applications. Plastic fittings are commonly used in irrigation systems, providing durability, corrosion resistance, and ease of installation in various agricultural settings. They are suitable for transporting water, chemicals, and other fluids necessary for irrigation and crop cultivation.

Send your message to us

3/4 BSP PPR Plastic Pipe and Fittings for Household

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords