PPR Pipes and fittings of industrial are Hot Selling

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product description

Product introduction

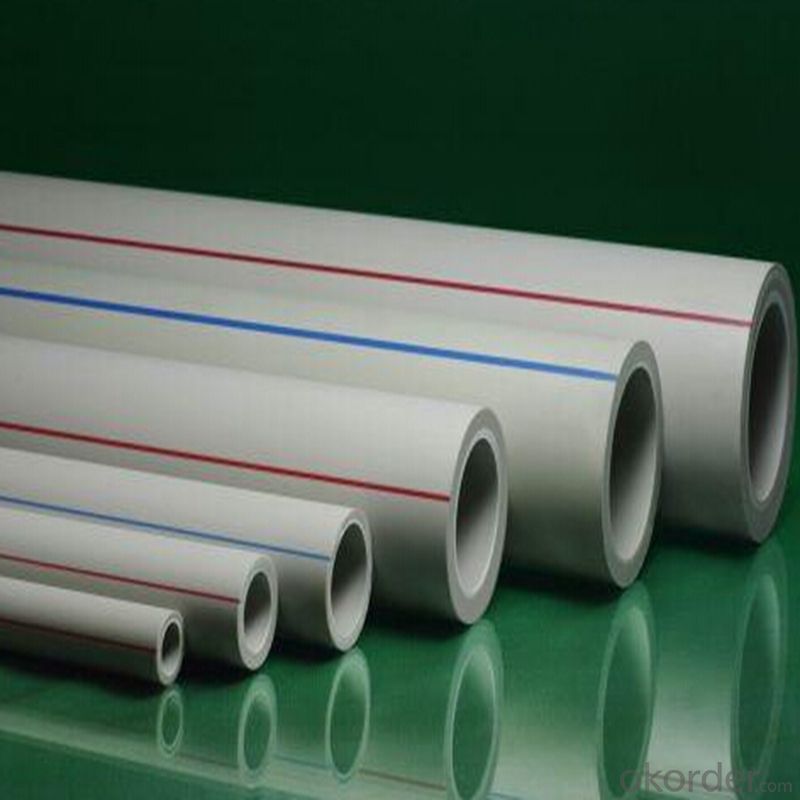

PP-R(polypropylene random)pipes are adopted thermal welding technique during the project of hot / cold water transmission. The comprehensive technical performance and economic indicator of PP-R are much better than galvanized pipe, UPVC pipe, polyethylene-aluminum compound pipe, PE-X (cross-linked polyethylene) and polybutylene pipe etc. For this reason PP-R is the leading products and widely used for feed-water piping in developed countries in Europe and America.

Product Applications

Distribution for cool and hot water

Duct for drinkable water system

Pipes for kinds of high-temperature and low-temperature heating system

Pipes for heating and coolling settings in solar energy system

Connecting pipe for air conditioners

PP-R Pipes & Fittings Advantage

1.More than 15 years of producing experience.

2.Light weight and small volume components,which is easy for installation and transportation.

3.Healthful and nontoxic:the product belongs to environmental green protective building materials.It can be used in the piping system of pure water and drinking water.

4.High temperature resistance:the maximum sustained working temperature is up to 70°c,the maximum transient temperature is up to 95°. white ppr pipe with red and blue line with ppr hyosung raw material

5.Higher flow capacity: smooth interior walls result in lower pressure loss and higher volume than metal pipes.

6.Attractive appearance and professional design.

7.Competitive price. white ppr pipe with red and blue line with ppr hyosung raw material

8.Long service life:more than 50 years under normal condition.

9.100% leakage testing,ensuring the tightness.

Specifications

1) Material: PPR, brass and others

2) Products: Pipelines for water supply and drain , Female and male Coupling ,Socket, Cap , Tee , Adapter , Elbow , Reducer, Union , Pipe Clip , Valve , and so on

3) Size: 20mm-110mm

4) Standard: DIN,GB

5) Life span: at least 50 years

6) Connection: Socket fusion joint, electro fusion joint, male and female thread joint

Packaging & Delivery

Our Service

1.Any inquiries will be replied within 24 hours

2.Professional manufacturer.

3.OEM is available.

4.High quality, standard designs,reasonable&competitive price,fast lead time.

5.Faster delivery: Sample will be prepared in 2-3days.

6.Shipping: We have strong cooperation with sea transportation land transportation air transport,ect

7.You can also choose your own shipping forwarder

- Q: How do plastic pipe fittings differ from metal pipe fittings?

- Plastic pipe fittings differ from metal pipe fittings primarily in terms of material composition, cost, and durability. Plastic fittings are made from materials like PVC, CPVC, or PEX, while metal fittings are typically made from materials like brass, copper, or stainless steel. Plastic fittings are generally less expensive than metal fittings, making them a more budget-friendly option. However, metal fittings are often considered more durable and have higher temperature and pressure resistance compared to plastic fittings. Ultimately, the choice between plastic and metal pipe fittings depends on the specific requirements of the plumbing system and the preferences of the user.

- Q: Can plastic pipe fittings be used in hot tub systems?

- Yes, plastic pipe fittings can be used in hot tub systems. However, it is important to ensure that the fittings are made from high-quality, heat-resistant materials such as PVC or CPVC that can withstand the high temperatures and chemicals commonly found in hot tubs. It is also recommended to consult the manufacturer's guidelines and local building codes to ensure compliance and safety.

- Q: Can plastic pipe fittings be used in fish farming systems?

- Yes, plastic pipe fittings can be used in fish farming systems. Plastic fittings are commonly used in aquaculture due to their durability, chemical resistance, and affordability. They are suitable for various applications, such as water supply, drainage, aeration, and filtration systems in fish farming operations.

- Q: Can plastic pipe fittings be used in DIY projects?

- Yes, plastic pipe fittings can be used in DIY projects. They are commonly used for plumbing and irrigation systems, as they are easy to work with, affordable, and resistant to corrosion. However, it is important to ensure that the fittings are compatible with the specific type of plastic pipe being used and that they are installed correctly to ensure a secure and leak-free connection.

- Q: How do plastic pipe fittings work?

- Plastic pipe fittings work by connecting and sealing sections of plastic pipes together to create a secure and reliable plumbing system. These fittings typically have threaded ends or are designed to be glued onto the pipes. They use various mechanisms such as compression, push-to-connect, or solvent welding to ensure a tight and leak-free connection. Plastic pipe fittings are versatile, durable, and resistant to corrosion, making them a popular choice for many plumbing applications.

- Q: Can plastic pipe fittings be used for stormwater management systems?

- Yes, plastic pipe fittings can be used for stormwater management systems. They are commonly used due to their durability, corrosion resistance, and ease of installation. Plastic pipe fittings are able to withstand the demands of stormwater management systems and can effectively convey and control the flow of stormwater.

- Q: Are plastic pipe fittings resistant to chlorine gas?

- Yes, plastic pipe fittings are generally resistant to chlorine gas.

- Q: Do plastic pipe fittings require any special tools for removal?

- Yes, plastic pipe fittings often require special tools for removal. The most common tool used is a pipe wrench or pliers specifically designed for plastic fittings. Additionally, some fittings may require the use of heat or solvent-based products to loosen the joints before removal.

- Q: Can plastic pipe fittings be used for compressed air energy storage?

- No, plastic pipe fittings are not recommended for compressed air energy storage. Compressed air systems require high-pressure applications, and plastic fittings may not have the necessary strength or durability to handle the pressure. It is advisable to use fittings made from materials like metal, such as steel or brass, which can withstand the high pressures involved in compressed air energy storage.

- Q: What's the size of the PPR pipe?

- Using a special scissors cutting vertical pipe, the incision should be smooth, without burr, such as must be cleaned before welding, welding parts, cleaning pipes and fittings, avoid sand and dust quality joint damage.Two. Mark the depth of the end of the tube with a marker.Three, with the welded pipe size matching heating head assembly welding machine, connect the power supply, waiting for heating head to achieve the most work temperature (260 + 10 degrees Celsius)Four. Meanwhile, pipe and fittings are inserted into the welding machine and heated according to the prescribed time. The heating time is shown in the hot melt connection process parameter table

Send your message to us

PPR Pipes and fittings of industrial are Hot Selling

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords