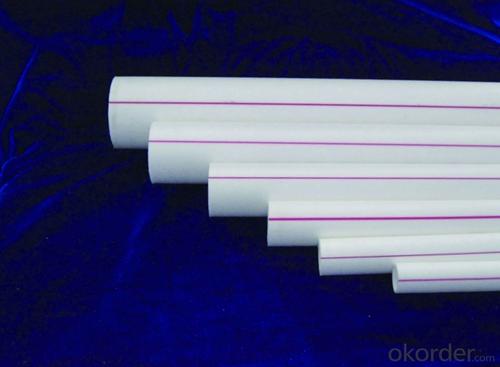

Plastic Tubes for PPR Pipes and Fittings for Hot and Cold Water Conveyance from China Factory

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Overview

1) Cold / hot water supply facilities for public buildings

2) Food, chemical, electronic industry pipeline networks; Such as Pipeline networks for transporting all kinds of corrosive liquids

3) Drinking water production system pipeline networks; Such as Pure water and mineral water

4) Air conditioning facility pipelines

5) Compressed gas pipeline networks for industry

6) Pipeline networks for swimming pools

7) Pipeline networks for solar energy facilities

8) Agriculture and garden production transporting systems

Product Applications:

1.Distribution for cool and hot water

2.Duct for drinkable water system

3.Pipes for kinds of high-temperature and low-temperature heating system

4.Pipes for heating and coolling settings in solar energy system

5.Connecting pipe for air conditioner

Why Us?

1.We can make any requirements in design, pattern, color and size.

2.We can make customer's logo on the surface of products.

3.The dimension tolerance of our products is controlled within 0.03mm.

4.Our products are child safety, pet safety and environment-friendly.

5.Our products are exported to America, Europe, India, west Asia, etc., and conforms to the standard test

Product Specification

1.Material : | PPR |

2.Color: | White, Gray, Green, or as you required. |

3.Size: | 20-110mm |

4.Logo: | CMAX or Customized |

5.MOQ | 500pcs |

6.Samples Time: | (1) 4-5days-If you want to customize your logo. |

(2) 1day-For our existing samples for reference. | |

7.OEM Accepted | Yes |

8.Certification available: | Yes |

9.Packing Details: | Weaving Bag |

10.Production Capacity: | 5,000,000pcs Per month. |

11.Payment Term: | (1) L/C,T/T,D/P |

Product Show

FAQ

Q1: How Can I Get A Sample?

A1: You can get samples by communicate with our export sales.

Q2: How Long Is Delivery?

A2: Delivery time will be30-45days according to order quantity.

Q3: What Is The MOQ?

A3: MOQ depends on different items.

Q4: What Is Our Normal Payments Terms?

A4: Our normal payment terms now is: T/T, L/C or western union, pay

- Q: Are plastic tubes microwave-safe?

- No, plastic tubes are generally not microwave-safe as they can melt or release harmful chemicals when exposed to high temperatures. It is recommended to use microwave-safe materials such as glass or ceramic when heating food or liquids in the microwave.

- Q: My friend gave me a bunch of mortars and i have never set off mortars before and i was wondering what you could use for a tube. Also how long does it need to be? first answer gets voted best by me

- Fiberglass Mortar Tubes

- Q: An air core is no core except air.

- Cute, but I saw the punch line back with the first bird.

- Q: What are the ways to remove the taste in plastic pipes?

- Method for removing peculiar smell of plastic pipe by vinegar. Clean the plastic tube with detergent first. Then soak the plastic tube in the vinegar and heat to 50-60 degrees. Keep the temperature. After 30 minutes, take out the plastic tube and clean it;

- Q: Are plastic tubes suitable for pneumatic conveying systems?

- Yes, plastic tubes are suitable for pneumatic conveying systems. They offer several advantages such as being lightweight, corrosion-resistant, and cost-effective. Plastic tubes also provide smooth internal surfaces, minimizing friction and enhancing the flow of materials. Additionally, they can withstand high-pressure environments and are available in various sizes and configurations, making them versatile for different pneumatic conveying applications.

- Q: Would exsanguination happen? Say the plastic tube is inserted and then left ignored. Blood flows out through the tube.Would the blood clot in the tube? Would the vein involved constrict and cut off flow? Would the patient die?

- It's unlikely that the patient would exsanguinate, especially if we are talking about a peripheral IV and not a central line. Yes, it is possible for blood loss to occur. Yes, blood can clot in the tube. This is what heplocks and flushes are for--to prevent this kind of thing when you don't have anything flowing through the IV.

- Q: Are plastic tubes suitable for use in the mining industry?

- Yes, plastic tubes are suitable for use in the mining industry. They offer several advantages such as being lightweight, corrosion-resistant, and easy to install. Plastic tubes are commonly used for conveying water, chemicals, and other materials in mining operations.

- Q: Anyone know where I can buy a custom tube (wood, aluminum, or plastic) with the following dimension...??I.D. : 4.0625 inchesO.D.: 4.1875 inchesLength: 1 inch (can be longer, of course)Ive been looking all over the net for custom plastic manufacturers but no success as of yet.Thanks!

- Do you really need spec.s to ten thousanths of an inch and not care about the nature of the material?

- Q: Are plastic tubes suitable for transporting hazardous materials?

- No, plastic tubes are generally not suitable for transporting hazardous materials as they may not provide adequate protection or resistance to chemical reactions or leaks.

- Q: How does transferring of liquid in a container to an empty container using a plastic tube works?

- You're talking about a siphon. You suck on the end to get the liquid up the tube and then down the other side, and all you need to do to keep it flowing is make sure the outside end of the tube is lower down than the inside end. The liquid pulls on itself, and there is more weight on the outer tube than the inner, so it's enough to draw the liquid up and down, as long as it ends up lower than it was before.

Send your message to us

Plastic Tubes for PPR Pipes and Fittings for Hot and Cold Water Conveyance from China Factory

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches