Grey Plastic PPR Pipe Fittings for Hot and Cold Drinking Water

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

Place of Origin: Henan, China (Mainland)

Model Number: PE100

Material: PE

Specification: DN 20-mm~DN1200mm

Length: According to customer requirement

Thickness:SDR11/13.6/17

Standard: ISO

Color: many colors

Product name: Plastic Pipe

Application: house and garden

Product Size

Outside Diameter(mm) | Wall Thickness(mm) | Package(m/bale) | |||

S5 PN1.25MPa | S4 PN1.6MPa | S3.2 PN2.0MPa | S2.5 PN2.5MPa | ||

20 | 2 | 2.3 | 2.8 | 3.4 | 120 |

25 | 2.3 | 2.8 | 3.5 | 4.2 | 120 |

32 | 2.9 | 3.6 | 4.4 | 5.4 | 80 |

40 | 3.7 | 4.5 | 5.5 | 6.7 | 60 |

50 | 4.6 | 5.6 | 6.9 | 8.3 | 40 |

63 | 5.8 | 7.1 | 8.6 | 10.5 | 24 |

75 | 6.8 | 8.4 | 10.1 | 12.5 | 16 |

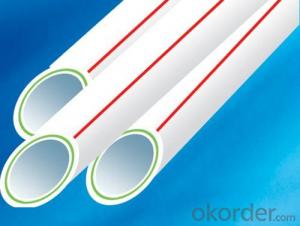

Product Show

Packaging & Shipping

Packaging Details:Carton

Delivery Time:30-45days

Applications

> Distribution for cool and hot water;

> Duct for drinkable water system;

> Pipes for kinds of high-temperature and low-temperature heating system;

> Pipes for heating and cooling settings in solar energy system;

> Connecting pipe for air conditioners;

Product Advantages

1)100% excellent raw materials ,safe and hygeian .

2)Drinking water pipeline system.

3)Recyclable ,benefit to the environment

4)Resistance to abrasion and corrosion.

5)Connected by heating ,leakage prohibit

6)Long lifespan,Minimum 50 years life time at 60 or 70°C and 10 bar maximum pressure.

FAQ

Q:What's your raw material? A: We use 100% new raw material.

Q: What is your MOQ? A: As customer's request. ( For example: PPR pipe DN20, MOQ 3000m)

Q:How is the production ability?or delivery time? A:40 HQ order finishing in one week

Q: What is the regular shipping port? A: Shanghai or Ningbo.

Q: Can we have sample? A: Sample free, but overseas freight costs you.

- Q: How do plastic pipe fittings differ from metal pipe fittings?

- Plastic pipe fittings differ from metal pipe fittings primarily in terms of material composition, cost, and durability. Plastic fittings are made from materials like PVC, CPVC, or PEX, while metal fittings are typically made from materials like brass, copper, or stainless steel. Plastic fittings are generally less expensive than metal fittings, making them a more budget-friendly option. However, metal fittings are often considered more durable and have higher temperature and pressure resistance compared to plastic fittings. Ultimately, the choice between plastic and metal pipe fittings depends on the specific requirements of the plumbing system and the preferences of the user.

- Q: Can plastic pipe fittings be used for rainwater collection systems?

- Yes, plastic pipe fittings can be used for rainwater collection systems. Plastic pipe fittings are commonly used in these systems due to their durability, resistance to corrosion, and affordability. They are also lightweight and easy to install, making them a popular choice for rainwater collection projects.

- Q: Spiral drain pipe fittings are not special pipe fittings

- Because the product of the tube holes in the trough, and elongated, effectively overcomes the planar circular hole is easy to block defects affect product drainage effect, according to the requirements of different drainage tube hole size is 10mm * 1MM-30MM * 3mm, and at 360 degrees, 270 degrees, 180 degrees, 90 degrees. Within the scope of the uniform distribution, widely used in highway, railway subgrade, subway engineering, waste landfill, tunnel, greening slope protection drainage belt, athletic field and high water content caused by agriculture, gardening, and underground irrigation and drainage system. It has become the three main products of civil engineering construction (water seepage, drainage) with soft permeable pipe and plastic blind ditch. According to the drainage pressure of municipal drainage network, double arm bellows and straight wall pipe can be used. The pressure of the straight wall pipe is stronger, and it can be used in the special pipe of large-scale drainage and sewage pipe network.

- Q: Are plastic pipe fittings suitable for compressed gas applications?

- No, plastic pipe fittings are not suitable for compressed gas applications.

- Q: How do plastic pipe fittings compare to brass fittings?

- Plastic pipe fittings are generally more affordable and easier to install compared to brass fittings. However, brass fittings are known for their durability, higher resistance to heat and pressure, and better overall performance in terms of longevity. It ultimately depends on the specific needs and budget of the project.

- Q: Can plastic pipe fittings be used for sewage systems?

- Yes, plastic pipe fittings can be used for sewage systems. Plastic materials such as PVC (polyvinyl chloride) and ABS (acrylonitrile butadiene styrene) are commonly used in sewage systems due to their durability, corrosion resistance, and cost-effectiveness. These fittings are designed to handle the demands of sewage transport and are widely accepted in the plumbing industry for sewage applications.

- Q: Are plastic pipe fittings suitable for underground sprinkler systems?

- Yes, plastic pipe fittings are suitable for underground sprinkler systems. They are durable, resistant to corrosion, and provide a cost-effective solution for irrigation systems. Additionally, plastic pipe fittings are lightweight and easy to install, making them a popular choice for underground sprinkler systems.

- Q: Can plastic pipe fittings be used for industrial waste disposal systems?

- Yes, plastic pipe fittings can be used for industrial waste disposal systems. Plastic pipe fittings are commonly used in industrial applications due to their durability, corrosion resistance, and ability to handle various chemicals. They provide a reliable and cost-effective solution for industrial waste disposal systems.

- Q: Can plastic pipe fittings be used for nuclear power plants?

- No, plastic pipe fittings cannot be used for nuclear power plants. Nuclear power plants require materials that can withstand extreme temperatures, high pressures, and are resistant to radiation. Plastic is not capable of meeting these crucial safety and performance standards.

- Q: Are plastic pipe fittings compatible with push-to-connect fittings?

- Yes, plastic pipe fittings are compatible with push-to-connect fittings.

Send your message to us

Grey Plastic PPR Pipe Fittings for Hot and Cold Drinking Water

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords