Copper Pipe Into Plastic Fitting - PPR Pipe and Fittings Used in Industrial Fields 2024 New

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

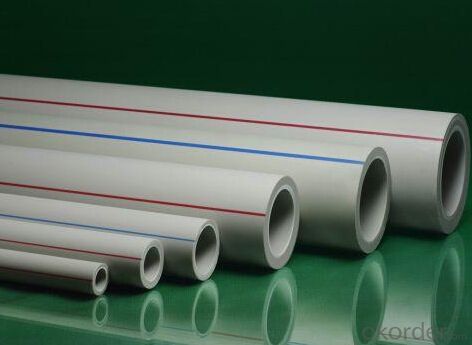

Introduction of Products

1.It is used in industrial fields

2. Beauty appearance.

3.Thermal insulation and energy saving.

4. Easy installation

5.excellent heat resistance and pressure resistance

size

1.25MPa | 1.6MPa | 2.0MPa | 2.5MPa | |

Outer | Wall | Wall | Wall | Wall |

Diameter | Thickness | Thickness | Thickness | Thickness |

dn(mm) | en (mm) | en (mm) | en (mm) | en (mm) |

20 | 2.0 | 2.3 | 2.8 | 3.4 |

25 | 2.3 | 2.8 | 3.5 | 4.2 |

32 | 2.9 | 3.6 | 4.4 | 5.4 |

40 | 3.7 | 4.5 | 5.5 | 6.7 |

50 | 4.6 | 5.6 | 6.9 | 8.3 |

63 | 5.8 | 7.1 | 8.6 | 10.5 |

75 | 6.8 | 8.4 | 10.1 | 12.5 |

90 | 8.2 | 10.1 | 12.3 | 15.0 |

110 | 10 | 12.3 | 15.1 | 18.3 |

160 | 14.6 | 17.9 | 21.9 | 26.6 |

Specification

1.Material: | PPR |

2.Color: | White, Gray, Green, or as you required. |

3.Size: | 20-110mm |

4.Logo: | CMAX or Customized |

5.MOQ | 500pcs |

6.Samples Time: | (1) 4-5days-If you want to customize your logo. |

(2) 1day-For our existing samples for reference. | |

7.OEM Accepted | Yes |

8.Certification available: | Yes |

9.Packing Details: | Weaving Bag |

10.Production Capacity: | 5,000,000pcs Per month. |

11.Payment Term: | (1) L/C, T/T, D/P |

Applications of PPR Pipe (white, gray):

1) Cold and hot water supply systems for civil and industrial constructions, e.g. in residential buildings, hospitals, hotels, school and office buildings, ship building

2) Drinking water systems and food industry pipe works

3) Central air conditioning system

4) Irrigating system for gardens and green houses

5) Public and sport facilities such as swimming pools and stadiums

6) For rainwater utilization systems

Packaging Details:

1. Large carton: 515 x 400x 220 Cubage: 0.04532 M3

Small carton: 390x255x250 Cubage: 0.0248 M3

2. PE poly bag+ carton Delivery Detail: 15 days/ 20" containers; 25 days/ 40HQ

FAQ

Q1: How Can I Get a Sample?

A1: You can get samples by communicate with our export sales.

Q2: How Long Is Delivery?

A2: Delivery time will be30-45days according to order quantity.

Q3: What Is The MOQ?

A3: MOQ depends on different items.

Q4: What Is Our Normal Payments Terms?

A4: Our normal payment terms now is: T/T, L/C or western union, MoneyGram.

- Q: Can plastic pipe fittings be used in DIY projects?

- Yes, plastic pipe fittings can be used in DIY projects. They are commonly used in various plumbing and irrigation applications due to their durability, affordability, and ease of installation. However, it is important to ensure that the fittings are compatible with the specific type and size of plastic pipes being used, and to follow proper installation guidelines to ensure a secure and leak-free connection.

- Q: What are the common materials used for plastic pipe fittings?

- Common materials used for plastic pipe fittings include PVC (polyvinyl chloride), CPVC (chlorinated polyvinyl chloride), PEX (cross-linked polyethylene), and ABS (acrylonitrile butadiene styrene).

- Q: Are plastic pipe fittings resistant to rodents?

- Yes, plastic pipe fittings are generally resistant to rodents. Unlike other materials like metal or wood, plastic does not attract rodents due to its lack of nutritional value. Additionally, plastic fittings are typically seamless, leaving no gaps or openings for rodents to access or damage the pipes.

- Q: How do you connect plastic pipe fittings to copper pipes?

- To connect plastic pipe fittings to copper pipes, you can use a transition fitting. This fitting typically has a threaded end that screws onto the plastic fitting, while the other end is soldered or brazed onto the copper pipe. It creates a secure and leak-proof connection between the two different materials.

- Q: What is the purpose of plastic pipe fittings?

- The purpose of plastic pipe fittings is to connect and join different sections of plastic pipes together, creating a secure and leak-proof plumbing system.

- Q: How long do plastic pipe fittings typically last?

- Plastic pipe fittings typically have a lifespan of around 50 to 100 years, depending on factors such as the type of plastic used, quality of installation, and exposure to environmental conditions.

- Q: How do plastic pipe fittings work?

- Plastic pipe fittings work by connecting sections of plastic pipes together in a leak-proof manner. They are designed with various shapes, sizes, and connections to accommodate different pipe systems. These fittings usually have threads, sockets, or grooves that allow them to be securely attached to the pipe ends. The fittings create a tight seal using compression, glue, or heat fusion methods, ensuring that the pipes remain connected and prevent any leakage.

- Q: Are plastic pipe fittings suitable for potable water distribution networks?

- Yes, plastic pipe fittings are suitable for potable water distribution networks. They are commonly used in such systems due to their durability, corrosion resistance, and ability to handle high pressure. Additionally, plastic pipe fittings are lightweight, easy to install, and cost-effective, making them a practical choice for potable water distribution.

- Q: Do plastic pipe fittings require any special tools for removal?

- Yes, plastic pipe fittings often require special tools for removal. These tools may include pipe wrenches, pliers, or specialized fittings removal tools, depending on the type of fitting being used.

- Q: Can plastic pipe fittings be used in medical gas systems?

- No, plastic pipe fittings should not be used in medical gas systems. These systems require materials that meet strict safety and regulatory standards to ensure the integrity and purity of the gases being delivered. Metal pipe fittings, such as copper or stainless steel, are typically used in medical gas systems due to their durability, resistance to corrosion, and ability to maintain gas purity.

Send your message to us

Copper Pipe Into Plastic Fitting - PPR Pipe and Fittings Used in Industrial Fields 2024 New

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords