High-Quality PPR Male Adaptor Plastic Tubes for Drinking Water Transport - Chinese Factory

- Loading Port:

- Tianjin

- Payment Terms:

- L/C,T/T

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 50000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Features

1. Corrosion resistance

PPR pipes and fittings can resistant to most chemical corrosion; it can withstand PH value range 1-14 high concentration of acid and alkali corrosion over a wide temperature range.

2. Installation performance

PPR pipe PPR pipe is light in weight, and the operation installation is easy, which make it available to weld again. It is very important that pipe and pipe fittings can be welded together in seconds with a simple tool. Compared to traditional connection methods it can save 40%~50% of the time.

3. Safety Indicators

The basic component of PPR is carbon and hydrogen which is simple. It keeps in line with food hygiene regulations, non-toxic. If you use PPR pipe, there will no dirt in the inner wall or “secondary water pollution” caused by rust any more.PPR pipe ,green building materials, is more suitable for transporting drinking water.

Advantages of PPR pipe

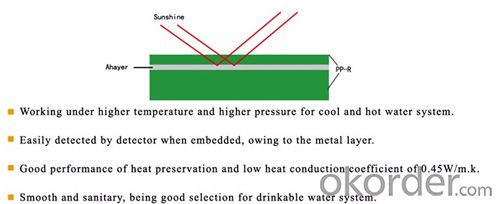

1. Maximum operating temperature can up to 95℃; it can work in a long term under the condition of 70℃ and 1.0Mpa.

2. PPR pipe density is only 1/8 of metal pipe; pressure resistance strength test is up 5Mpa, with good toughness, impact resistance.

3. Inner diameter of PPR pipe is little bigger than that of pipe fittings, which can ensure not to increase the resistance to fluid flow.

4. Inner wall of PPR pipe is smooth, no rust, no scaling, small fluid resistance

5. PPR pipe has excellent insulation properties, can significantly reduce the vibration and noise caused by the flow of liquid.

6. PPR pipe energy consumption is only 20% of steel pipe; its thermal coefficient is also only 1/200 of steel pipe, reducing heat loss greatly.

7. PPR pipe is poor electrical conductor material, which can avoid galvanic corrosion phenomena.

8. With poor thermal conductivity, PPR pipe can reduce condensation.

9. PPR pipes, fittings are recyclable.

Application

1. Hot and cold drinking water supply system of civil and industrial buildings

2. Clean, pure water piping system

3. Beverage production and transport systems

4. Industrial liquid delivery system

5. Central air conditioning system

6. Hot water circulation Heating System

7. Compressed air piping system

8. Garden and greenhouse irrigation systems

Construction Installation Guide of PPR Pipe

I. General Provisions

1. Before the pipeline installation and construction, should be with the following conditions:

a Drawings and other technical documents complete, and has been drawing technical tests, meet the construction requirements;

b Construction plan, construction techniques, materials and other equipment to ensure the normal supply of construction;

c Should be applied to the technical training of personnel through building water supply polypropylene pipeline installation.

2. Pipes and fittings provided shall meet the design requirements, along with the product specification and quality certification.

3. Do not use the material for signs of damage. Pipeline quality found abnormalities, should be identified prior to use technology or re-examination.

4. Pipeline system during installation openings should be blocked.

5. The construction should review the installation of cold, hot water pipe pressure rating and usage scenarios. Pipeline markers should be open to the outside, in a prominent position.

Second, the pipeline laying installation points

1. The pipe-wall Concealed, should be set aside with the civil recess dimensioned not specified, in-wall underground pipe wall groove depth De ten sizes 20mm, width of dry De + 40 ~ 60mm. Quiet concave surface must be smooth, without sharp corners and other projections, the pipeline pressure test, the groove wall with cement mortar to fill dense M7.5 class.

2. Pipeline Concealed in the floor surface, according to the design drawing position. As applied to the site there is a change, there should be shown the recording.

3. PPR installation, without axial distortion, when the wall or floor, the correction should not be mandatory. Polypropylene water pipes should be laid in parallel with other metal pipes have some protection from the net distance should be less than 100mm, and it should polypropylene tubes on the inside of the metal pipe.

4. The indoor surface mounted pipeline, should be carried out after the completion of the civil whitewash, the installation should be reserved holes with the civil right or top manager sleeve.

5. The pipe through the floor should be provided with steel casing, the casing above the ground 50mm, and a waterproofing. If the pipeline crosses roofing, waterproofing should be taken strict measures. It should be set through the front-end bracket.

6. When the hot water pipes through the wall, should be set up with civil steel casing, when the cold water pipe through the wall, can be reserved hole, the hole size than the outer diameter of 50mm.

7. Buried in the ground floor surface as well as inside the pipe wall, pressure test should be prepared and hidden works acceptance records for shelter before the closure.

8. Building physics introduction pipe and buried pipe laying indoor requirements are as follows:

a. Indoor floor the following pipeline 0.00 disabilities should be divided in two phases. 0.00 The following persons Floor laying the foundation wall to wall section to be first; after the paternity civil construction, then the outdoor connection pipe laying;

b. Indoor floor the following pipeline should be after the construction backfill compaction, re-excavation carried out. Prohibited in the soil before or without backfill compaction of laying;

c. The laying of the pipeline ditch should be flat; one must highlight the sharp hard object. Soil particle diameter of is not more than 12mm, to 100mm thick sand cushion shop when necessary.

d. When the buried pipeline backfill, backfill pipe circumference shall inclusion sharp hard object from indirect contact with the wall. Backfill soil should be sand or particles of diameter of not more than 12mm to the top of the pipe at the side 300mrn, after compaction before backfill the original soil. Indoor buried pipeline buried depth of not less than 300mnl;

e. Pipeline floor should be set at a protective tube with a height above ground assessment 100mnl;

f. The pipeline through the foundation wall should be provided with a metal sleeve. Casing and foundation wall reserved headroom above the hole, special design not less than 100mm;

g. Pipeline crossing the neighborhood road, when Futuhoudu less than 700mm, should adopt strict protection measures.

- Q: I am doing a project and i have a plastic tube that need to go in circles so i need to straighten it. Any Ideas? I need this fast please. :)

- Blow dryer on high or a heat gun on low. The heat gun will be the most likely to work. Not knowing your age I will say that you can get your parents to put it in your oven and set the temp for say 170F or less and heat it for 3-6 min. That will soften it up but if your oven does not go that low forget that method. The oven method would be my last choice. Just thought of one. If you have a rice cooker or steamer that may work if it is big enough. The steam will heat it but not burn it. But again if you are a minor have your parents do it. This you will have to watch and again it would not be my first choice.

- Q: I am using a device to push small volumes (60-100cc) through a plastic tube with a length of approx 24 and a diameter of 1mm or less. I can control flow rate, generally 2-4cc/sec. The liquid has a higher viscosity than water. I am trying to determine the difference in pressure on the piston face (which remains a constant size) using different fluids with slightly different viscosities through tubing of the same length, and differences in pressure using the same fluid through different tubing lengths. Ie; Fluid A and Fluid B through Tube 1, and Fluid A through Tube 1 and 2. The tubes are the same material, same diameter, regardless of length. The pressure used to push the piston remains the same across all fluid/tubing combinations.

- If the flow is not turbulent (no high speeds) and incompressible, and the tube is of circular cross section, then Poiseuille Law flow will ensue. In Poiseuille flow through a cylindrical pipe the velocity is largest along the centerline of the tube and diminishes to zero at the inner wall quadratically with distance r: v(r) = c (R^2 - r^2) with c a constant for given viscosity and pressure gradient ( delta(p) / L ) In Poiseuille flow through a cylindrical pipe the rate of flow (volume/second) is given by Qdot, where Qdot = ( Delta(p) pi R^4 ) /(8 eta L). (where eta is the dynamic viscosity of the fluid) Since the pressure difference Delta(p) is the pressure on the piston face - ambient pressure , let's call this (p - p0) , you have p - p0 = ( 8 eta L) * Qdot /(pi R^4) Using this Poiseuille' s Law you can calculate the pressure on the piston. You say at the end of your question that the pressure used to push is kept constant. In that case the flow rate you measure should be inversely proportional to eta and L.

- Q: Plastic tubing is touching compressor (or close to it) and gets hot and brittle. I recoupled a bad spot 1 year ago and it is leaking again. I would like to replace the tubing from the back of the refrig (solenoid) to the water filter. Any ideas on what material to use? I would like to use copper line thru the bottom of the refrig if not all the way to the water filter, but don't know how to connect it to the solenoid. Also would pex (1/4 OD) line be a better (albeit more expensive) choice for this?

- You can replace the line with copper. If the connection point is metal you'll want to use a brass compression nut (brass) with a (brass) compression sleeve (know as a ferrules) if the connection point is plastic you'll want to use a nylon compression fitting. The metal ferrules one wont work as you would need to crank the you know what out out it to make it seal, and run the risk of stripping the plastic threads. The nylon takes less torque to seal if that makes sense as its a more dense material. You should be able to get all the parts from a local hardware store or big box store such as lowes or homedepot.

- Q: Can plastic tubes be used for packaging cosmetics?

- Yes, plastic tubes can be used for packaging cosmetics. They are commonly used due to their versatility, flexibility, and ability to protect the contents from moisture and contamination. Plastic tubes also offer convenience in terms of dispensing the product and can be easily customized for branding purposes.

- Q: Are plastic tubes resistant to discoloration?

- Yes, plastic tubes are generally resistant to discoloration.

- Q: What's the name of that plastic tube used to fold stars?

- (1) the straw is bent back;(2) turn left pipe to the lower right;(3) turn the upper pipe to the left;(4) turn the two pipes together;(5) wrap the left tube over the right tube and fold it to the lower right;(6) wrap the upper tube over the lower tube;(7) the two pipes are turned together, with steps (4), repeating steps (4), (5), (6), (7);(8) stick the first angle close to the two pipes;(9) wrap the left tube over the first corner;(10) turn the top pipe down to the bottom;(11) repeat steps (9), (10) fold the tube to the end;(12) pass one of the tubes through the stars;(13) trim after tensioning;(14) complete

- Q: Are plastic tubes resistant to impact or pressure?

- Plastic tubes can vary in their resistance to impact and pressure depending on the specific type and quality of plastic used. Some plastic tubes can be designed to withstand high impact and pressure, while others may be more prone to damage. It is important to consider the intended use and specifications of the plastic tube to determine its level of resistance.

- Q: ...little grinding bits come in.The seal can be O.D. or I.D. and needs to slip on and off fairly easy, just like the seals in the tubes that contain the littler grinding bits Dremel makes.

- 1 piece of heat-shrink tubing to insulate your solder connection between EL wire and stereo wire (RadioShack) 1/2 6x32 clear polycarbonate screw to hold end bushing in (this is a recent addition, because the end bushings have come out of some of my blades when they are dueled with. However, these are rather expensive, as screws go. I think I payed about $10 for 50 screws.) hot glue, or silicone for end of blade super glue to glue in top and bottom bushings Note: I don't really like RadioShack all that much. I have a much better electronics store locally that I use that has a better selection and cheaper prices, but you can't order from them online, so I know you should be able to find what you need at RadioShack) That's just for the blade.

- Q: PVC plastic pipe in the underground, what need to diameter, the hoop and flange is a kind of thing?

- The flange is the part that connects the pipe to the pipe and is connected to the end of the pipe. Flange connection or flange connection, is defined by the flange, gasket and bolt connection between the three sealing structure of the detachable connection as a combination of group pipe flange refers to the pipeline installation of piping flange, used in equipment refers to equipment import and export flange. The flange is lined with bolts to secure the two flanges. Gaskets for gaskets between flanges. Flange, threaded joint flange and welding flange.

- Q: Can plastic tubes be used for hydroponic gardening?

- Yes, plastic tubes can be used for hydroponic gardening. They are commonly used as a component of hydroponic systems, serving as a conduit for nutrient-rich water to flow to the plants' roots. Plastic tubes are durable, easy to clean, and resistant to water and nutrient solutions, making them a practical choice for hydroponic gardening setups.

Send your message to us

High-Quality PPR Male Adaptor Plastic Tubes for Drinking Water Transport - Chinese Factory

- Loading Port:

- Tianjin

- Payment Terms:

- L/C,T/T

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 50000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords