3 Plastic Pipe Fittings - PPR Elbow Fittings of Industrial Application with Superior Quality 2024 New

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 PCS

- Supply Capability:

- 100000 PCS/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

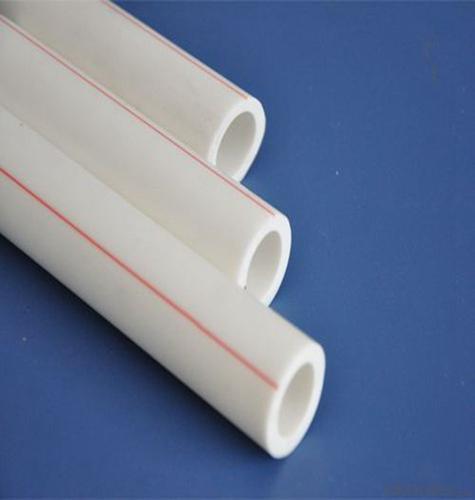

Description of Products:

PP-R (polypropylene random) tube called type three polypropylene pipe and is also called the PP-R pipe or PPR pipe, with energy saving, environmental protection, high strength, corrosion resistance, with smooth inner wall has the advantages of scale, construction and easy maintenance, long service life, widely used in building water supply and drainage, urban drainage city gas and power cable sheath, and industrial fluid transportation, agricultural irrigation construction, municipal, industrial and agricultural fields. The PP-R pipe is made of random copolymerized polypropylene and is extruded into tubes to be molded into tubes.

PPR Pipe Size:

Normal Sizes for CNBM PPR Pipe | |||||

Outside Diameter(mm) | Wall Thickness(mm) | Package(m/bale) | |||

S5 PN1.25MPa | S4 PN1.6MPa | S3.2 PN2.0MPa | S2.5 PN2.5MPa | ||

20 | 2 | 2.3 | 2.8 | 3.4 | 120 |

25 | 2.3 | 2.8 | 3.5 | 4.2 | 120 |

32 | 2.9 | 3.6 | 4.4 | 5.4 | 80 |

40 | 3.7 | 4.5 | 5.5 | 6.7 | 60 |

50 | 4.6 | 5.6 | 6.9 | 8.3 | 40 |

63 | 5.8 | 7.1 | 8.6 | 10.5 | 24 |

75 | 6.8 | 8.4 | 10.1 | 12.5 | 16 |

Specification:

Nominal diameter: DN20-DN110mm

Wall thickness: 2.0-18.3mm

Nominal pressure: S5/S4/S3.2/S2.5( 1.25-2.5Mpa)

Product physical properties:

Longitudinal retraction rate: < 2%

Melt Flow rate(230℃, 2.16kg):<0.5 g/10min

Hydraulic pressure test:

( 20 ℃, Cyclic stress 16 mpa, 1 h) : No leakage ,No damage.

( 20 ℃, Test pressure 5.05 mpa, 1 h) : No leakage ,No damage.

Application:

1) Cold / hot water supply facilities for public buildings

2) Food, chemical, electronic industry pipeline networks; Such as Pipeline networks for transporting all kinds of corrosive liquids

3) Drinking water production system pipeline networks; Such as Pure water and mineral water

4) Air conditioning facility pipelines

5) Compressed gas pipeline networks for industry

6) Pipeline networks for swimming pools

7) Pipeline networks for solar energy facilities

8) Agriculture and garden production transporting systems

Product Show:

Product Feature:

1. High Temperature Resistance: the maximum sustained working temperature is up to 70°C , the maximum transient temperature is up to 95°C

2. Heat Preservation: low thermal conductivity which is only 1/1500 of brass pipe, and 1/250 of steel pipe

3. Non-toxic: no heavy metal additives, would not be covered with dirt or contaminated by bacterium

4. Corrosion Resistance: resist chemical matters and electron chemical corrosion

5.High Flow Capacity: smooth interior walls and low friction result in low flow resistance and high volume

6. Excellent Flexibility: can be supplied in coil

7. Low Installation Costs: light weight and ease of installation can reduce installation costs

8. Longevity: more than 50 years under proper use

FAQ:

Q1: How Can I Get a Sample?

A1: You can get samples by communicate with our export sales.

Q2: How Long Is Delivery?

A2: Delivery time will be30-45days according to order quantity.

Q3: What Is The MOQ?

A3: MOQ depends on different items.

Q4: What Is Our Normal Payments Terms?

A4: Our normal payment terms now is: T/T, L/C or western union, MoneyGram.

- Q: Can plastic pipe fittings be used for swimming pool systems?

- Yes, plastic pipe fittings can be used for swimming pool systems. Plastic pipe fittings, such as PVC or CPVC, are commonly used in swimming pool systems due to their durability, corrosion resistance, and affordability. These fittings are designed to withstand the water and chemical environments typically found in swimming pools, making them a suitable choice for pool plumbing systems.

- Q: Can plastic pipe fittings be used for both residential and commercial applications?

- Yes, plastic pipe fittings can be used for both residential and commercial applications. They are versatile and commonly used in plumbing systems for both types of buildings due to their durability, ease of installation, and resistance to corrosion.

- Q: Can plastic pipe fittings be used for portable water systems?

- Yes, plastic pipe fittings can be used for portable water systems. However, it is important to ensure that the fittings are made of suitable materials, such as PVC or CPVC, which are specifically designed for use in potable water applications. Additionally, these fittings should meet the necessary standards and certifications to ensure they are safe and reliable for use in portable water systems.

- Q: Are plastic pipe fittings prone to clogging?

- No, plastic pipe fittings are not prone to clogging.

- Q: Are plastic pipe fittings resistant to freezing temperatures?

- Yes, plastic pipe fittings are generally resistant to freezing temperatures. Plastic materials such as PVC and CPVC are known for their ability to withstand low temperatures without cracking or breaking, making them suitable for use in cold environments.

- Q: Are plastic pipe fittings resistant to ammonia gas?

- Yes, plastic pipe fittings are generally resistant to ammonia gas.

- Q: Are plastic pipe fittings suitable for pharmaceutical manufacturing?

- No, plastic pipe fittings are generally not suitable for pharmaceutical manufacturing due to the risk of contamination and chemical reactions with the drugs or chemicals involved in the process.

- Q: What is the average lifespan of plastic pipe fittings?

- The average lifespan of plastic pipe fittings can vary depending on factors such as the type of plastic used, the conditions they are exposed to, and the quality of installation. However, in general, plastic pipe fittings can last anywhere from 20 to 50 years or more.

- Q: Can plastic pipe fittings be used for water supply in remote areas?

- Yes, plastic pipe fittings can be used for water supply in remote areas. Plastic pipes and fittings are lightweight, durable, and resistant to corrosion, making them suitable for long-distance transportation and installation in challenging terrains. Additionally, plastic pipes are cost-effective and easy to handle, making them a practical choice for remote areas with limited resources and infrastructure.

- Q: Are plastic pipe fittings resistant to thermal expansion?

- Yes, plastic pipe fittings are generally resistant to thermal expansion.

Send your message to us

3 Plastic Pipe Fittings - PPR Elbow Fittings of Industrial Application with Superior Quality 2024 New

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 PCS

- Supply Capability:

- 100000 PCS/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches