Plastic Pipes Fittings - 2024 PPR Elbow Fittings for Industrial Application

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Overview:

1.It is used in industrial fields, agriculture and irrigation.

2.Beauty appearance.

3.Thermal insulation and energy saving.

4.Easy installation

5.excellent heat resistance and pressure resistance

6.affordable price

Applications of PPR Pipe (white, gray):

1) Cold and hot water supply systems for civil and industrial constructions, e.g. in residential buildings, hospitals, hotels, school and office buildings, ship building

2) Drinking water systems and food industry pipe works

3) Central air conditioning system

4) Irrigating system for gardens and green houses

5) Public and sport facilities such as swimming pools and stadiums

6) For rainwater utilization systems.

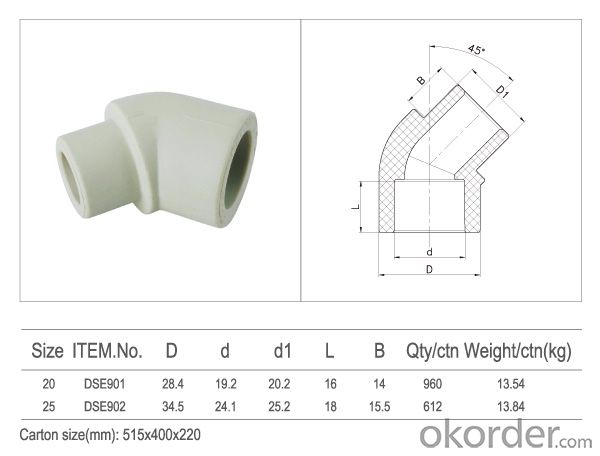

Product Description

Product Show

FAQ

Q: How do you guarantee the quality of your product?

A: Every process will be checked by responsible QC which insures every product's quality.

Q: How much is your delivery time?

A: Normally within 30 days of receipt of LC original or prepayment, but mostly according to the specific requirements or the quantity

Q: I need sample, could you support?

A: We can supply you with the sample for free, but the delivery charges will be covered by our customers. For avoiding the misunderstanding, it is appreciated if you can provide the International Express Account for Freight Collect. Also you can have a visit to us, welcome to CNBM!

- Q: Do plastic pipe fittings require special tools for installation?

- Yes, plastic pipe fittings often require special tools for installation. These tools may include pipe cutters, deburring tools, and heat guns for joining pipes using solvent welding or fusion methods. Additionally, some types of plastic pipe fittings may require specialized crimping or compression tools for secure installation.

- Q: Does the PPR plastic tube do any harm to your health? Is it big?

- Characteristics of PPR tubes:1, as a new type of water pipe material, PPR pipe is sanitary, non-toxic, no rust, no fouling, meet the international standards for drinking water.2, high temperature resistant, high pressure resistant, heat preservation and energy saving. Small resistance, fast flow, little noise.3, light weight, toughness, impact resistance, the specific gravity is only 1/8 of the metal tube, the pressure test strength of more than 50Kg/cm2. Easy installation, reliable connection, never leak. Under normal conditions, the service life can be up to 50 years.

- Q: Can plastic pipe fittings be used in fire-resistant systems?

- No, plastic pipe fittings cannot be used in fire-resistant systems as they have a low resistance to heat and can melt or release toxic fumes during a fire.

- Q: Can plastic pipe fittings be used for industrial cooling systems?

- Yes, plastic pipe fittings can be used for industrial cooling systems. They offer various advantages such as corrosion resistance, easy installation, and lower cost compared to traditional metal fittings. However, it is important to select fittings that are specifically designed for industrial cooling applications and can withstand the required temperature and pressure conditions.

- Q: How do plastic pipe fittings handle water treatment processes?

- Plastic pipe fittings are commonly used in water treatment processes due to their resistance to corrosion and chemicals, as well as their durability and ease of installation. They can handle the various stages of water treatment, such as filtration, disinfection, and chemical dosing, effectively and reliably. Plastic fittings also offer flexibility, allowing for easy modifications or expansions in the water treatment system if needed.

- Q: Can plastic pipe fittings be used in chemical processing systems?

- Yes, plastic pipe fittings can be used in chemical processing systems. Plastic materials such as PVC, CPVC, and polypropylene are commonly used in chemical processing due to their resistance to corrosion, chemicals, and high temperatures. Additionally, plastic pipe fittings are lightweight, easy to install, and cost-effective, making them suitable for various applications in chemical processing systems. However, it is crucial to choose the appropriate plastic material that is compatible with the specific chemicals and operating conditions of the system to ensure safety and reliability.

- Q: Can plastic pipe fittings be used for fire hydrant systems?

- No, plastic pipe fittings cannot be used for fire hydrant systems. Fire hydrant systems require durable and heat-resistant materials, such as cast iron or ductile iron, to withstand the high pressure and extreme temperatures associated with firefighting operations.

- Q: Are plastic pipe fittings resistant to ultrasonic vibrations?

- No, plastic pipe fittings are not generally resistant to ultrasonic vibrations.

- Q: Are plastic pipe fittings resistant to fire?

- No, plastic pipe fittings are not generally resistant to fire.

- Q: Can plastic pipe fittings be used in above-ground applications?

- Yes, plastic pipe fittings can be used in above-ground applications. They are commonly used for plumbing and irrigation systems due to their durability, versatility, and resistance to corrosion. However, it is essential to ensure that the fittings are suitable for above-ground use and compatible with the specific application to ensure proper functionality and longevity.

Send your message to us

Plastic Pipes Fittings - 2024 PPR Elbow Fittings for Industrial Application

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords